Phosphorus-free environment-friendly corrosion and scale inhibitor as well as preparation method and application thereof

A corrosion and scale inhibitor, an environmentally friendly technology, applied in the field of phosphorus-free and environmentally friendly corrosion and scale inhibitors and its preparation, can solve problems affecting the effect of phosphorus-free corrosion and scale inhibitors, monitoring data deviation, metal corrosion, etc. , to achieve excellent scale inhibition effect, promote integrity and reduce pitting corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of the tracer copolymer specifically comprises the following steps:

[0044] S1: Synthesis of Fluorescent Monomers

[0045] (1) Add 355g of glacial acetic acid and 63g of 4-chloro-1,8-naphthalenedicarboxylic acid anhydride in a 500mL three-necked glass bottle, start stirring, slowly add 30g of 3-dimethylaminopropylamine, and heat the temperature to 110° C. The temperature was cooled to 40°C for 5 hours, the stirring was stopped, the material was discharged into a 5L glass bottle, 2L pure water was added, the stirring was started, 460g of 48% sodium hydroxide was added to adjust the pH to 11, cooled to room temperature, and the stirring was stopped. Remove the liquid to obtain a brownish-yellow solid, bake at 85°C for 5 hours, and pulverize to obtain Intermediate 1;

[0046] (2) add 95g methanol, 26g sodium methoxide, 20g intermediate 1 into a 500mL three-neck glass bottle, start stirring, pass nitrogen for 20 minutes and then heat, the temperatur...

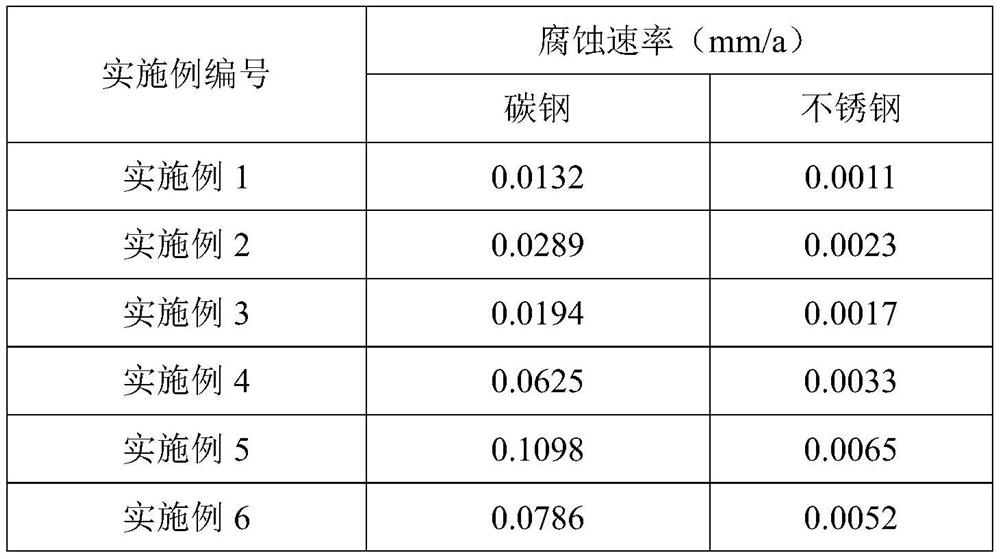

Embodiment 1

[0061] The first aspect of the present embodiment provides a phosphorus-free environment-friendly corrosion and scale inhibitor, which, in parts by weight, includes the following raw materials: 8 parts of inorganic salts, 10 parts of polyepoxysuccinic acid, benzotriazole 0.7 parts of azole, 8.8 parts of polyaspartic acid, 7.5 parts of hydrochloric acid, 2.8 parts of triethanolamine, 20 parts of tracer copolymer, and deionized water to make up to 100 parts.

[0062] The inorganic salt includes zinc chloride, sodium citrate, and lithium molybdate, and the weight ratio of the three is 1:1.5:1.5.

[0063] The polyepoxysuccinic acid was purchased from Nantong Runfeng Petrochemical Co., Ltd., and the polyaspartic acid was purchased from Hebei Synergy Environmental Protection Technology Co., Ltd.

[0064] The mass concentration of the hydrochloric acid is 30%.

[0065] The preparation method of the tracer copolymer specifically comprises the following steps:

[0066] S1: Synthesis ...

Embodiment 2

[0078] The first aspect of the present embodiment provides a phosphorus-free environment-friendly corrosion and scale inhibitor, which, in parts by weight, comprises the following raw materials: 5 parts of inorganic salts, 6 parts of polyepoxysuccinic acid, benzotriazole 0.6 parts of azole, 5.5 parts of polyaspartic acid, 6 parts of hydrochloric acid, 3 parts of triethanolamine, 12 parts of tracer copolymer, and deionized water to make up to 100 parts.

[0079] The inorganic salt includes zinc chloride, sodium citrate, and lithium molybdate, and the weight ratio of the three is 1:1.5:1.5.

[0080] The polyepoxysuccinic acid was purchased from Nantong Runfeng Petrochemical Co., Ltd., and the polyaspartic acid was purchased from Hebei Synergy Environmental Protection Technology Co., Ltd.

[0081] The mass concentration of the hydrochloric acid is 30%.

[0082] The preparation method of the tracer copolymer specifically comprises the following steps:

[0083] S1: Synthesis of F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com