Preparation method of mulberry fibers

A technology of mulberry fiber and cellulase, which is applied in the chemical post-treatment of fibers, fiber treatment, textiles and papermaking, etc., can solve the problems of complex operation, long process flow, environmental pollution, etc., and achieve smooth fiber surface and degumming rate High effect with little damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

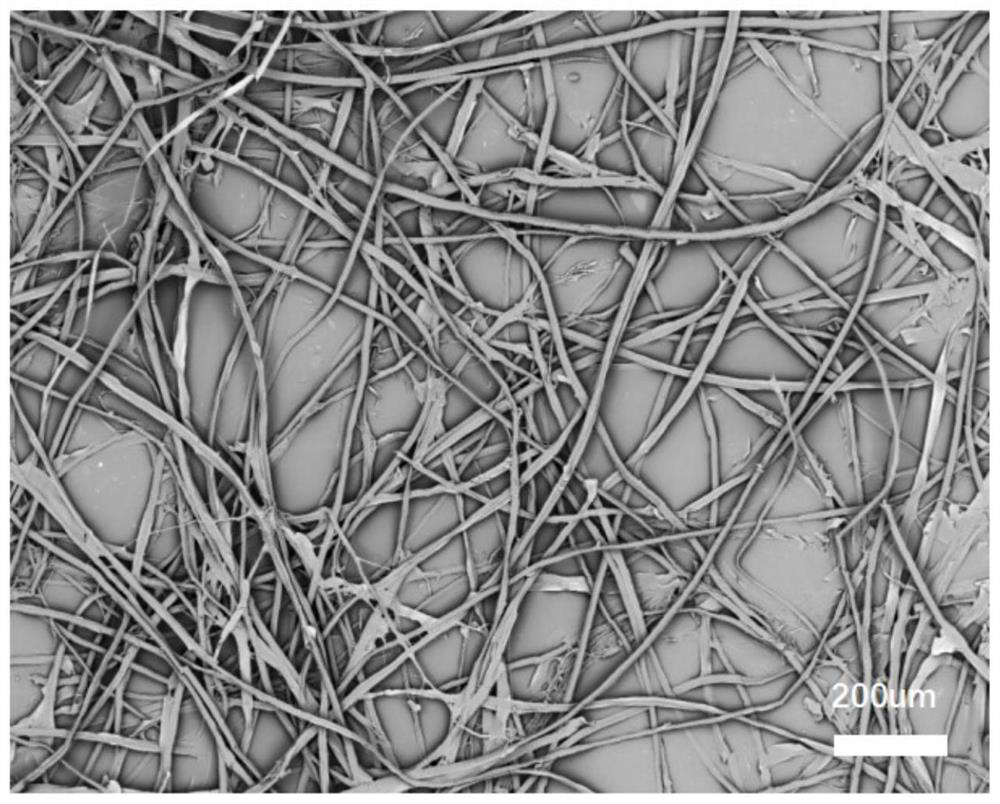

Image

Examples

preparation example Construction

[0022] The purpose of the present invention is to provide a preparation method of mulberry fiber, including impurity removal→microbial fermentation→enzymatic degumming→ultrasonic treatment.

[0023] Removal of impurities: refers to boiling and peeling of mulberry branches → mechanical beating of mulberry peels after washing → soaking mulberry peels in 75-80 ℃ impurity removal liquid for 3-5 hours; impurity removal liquid is formed by dissolving tea saponin, and the mass concentration is 4-6 g / L, The mulberry bark is soaked in impurity removal liquid, and the bath ratio is 1g: 17-20mL.

[0024] Microbial fermentation: refers to putting the mulberry bark after impurity removal in the compound bacterial culture solution at 26°C for 28 days, and then washing with water to remove the bacterial solution and part of the gum; the mass concentration of the mulberry bark treated with the compound bacterial community culture solution is 24% The complex flora includes Bacillus licheniform...

Embodiment 1

[0031] Preparation method of mulberry fiber:

[0032] (1) Removal of impurities: mulberry branches are boiled and peeled → mulberry peels are mechanically beaten after washing → soak mulberry peels in 80 ° C impurity removal liquid for 3 hours; impurity removal liquid is formed by dissolving tea saponin, and the mass concentration of impurity removal liquid is 5g / L, The mulberry bark is soaked in impurity removal liquid, and the bath ratio is 1:18;

[0033] (2) Microbial fermentation: put the impurity-removed mulberry bark in a compound bacterial culture solution at 26°C for 28 days, and then wash with water to remove the bacterial solution and part of the gum; the mass concentration of the mulberry bark treated with the composite bacterial community culture solution is: 24%; the complex flora includes Bacillus licheniformis, Bacillus subtilis and EM bacteria with a mass ratio of 1:0.2:0.5;

[0034] (3) Enzymatic degumming: put the mulberry bark after microbial fermentation i...

Embodiment 2

[0038] Preparation method of mulberry fiber:

[0039] (1) Impurity removal: mulberry branches are boiled and peeled → mulberry bark is washed and mechanically beaten → soaked mulberry bark in 75°C impurity removal solution for 5h; The mulberry bark is soaked in impurity removal liquid, and the bath ratio is 1:20;

[0040] (2) Microbial fermentation: put the impurity-removed mulberry bark in a compound bacterial culture solution at 26°C for 28 days, and then wash with water to remove the bacterial solution and part of the gum; the mass concentration of the mulberry bark treated with the composite bacterial community culture solution is: 24%; the complex flora includes Bacillus licheniformis, Bacillus subtilis and EM bacteria with a mass ratio of 1:0.3:0.5;

[0041] (3) Enzymatic degumming: put the mulberry bark after microbial fermentation in the degumming solution at 45 °C for 3 hours, and then wash with water to remove the degumming solution and gum; the mulberry bark is tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com