Manufacturing method of semiconductor structure and semiconductor structure

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, transistors, etc., can solve problems affecting the performance of transistors and access performance of DRAM devices, so as to improve switching speed, reduce quantum tunneling effect, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

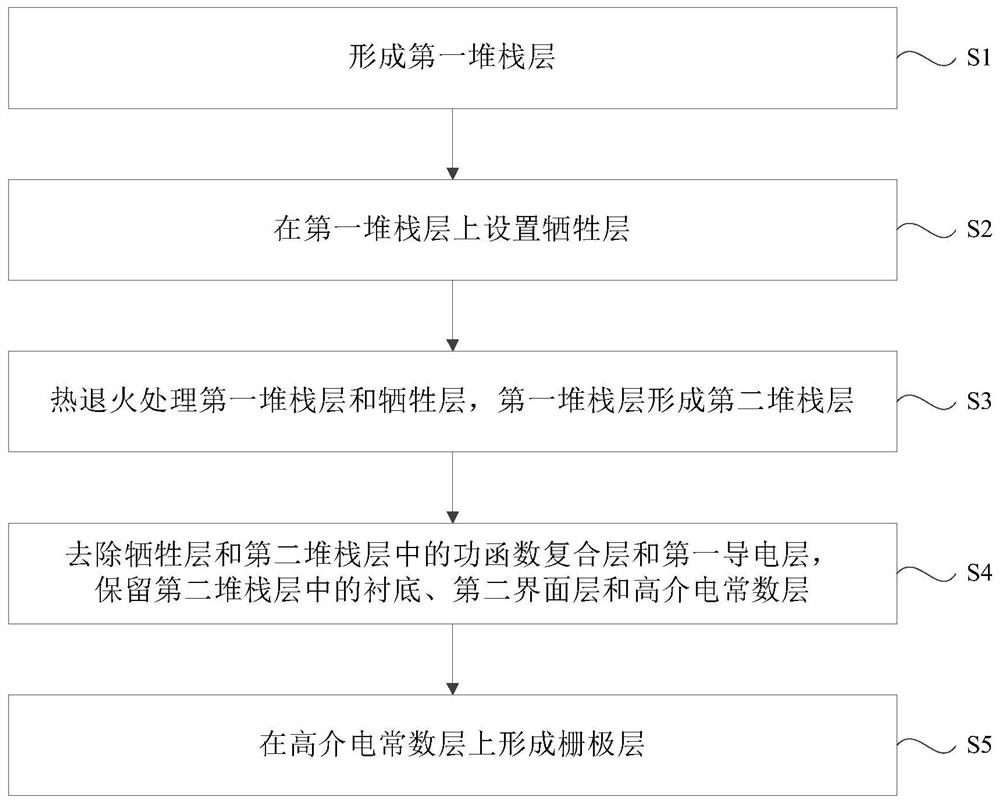

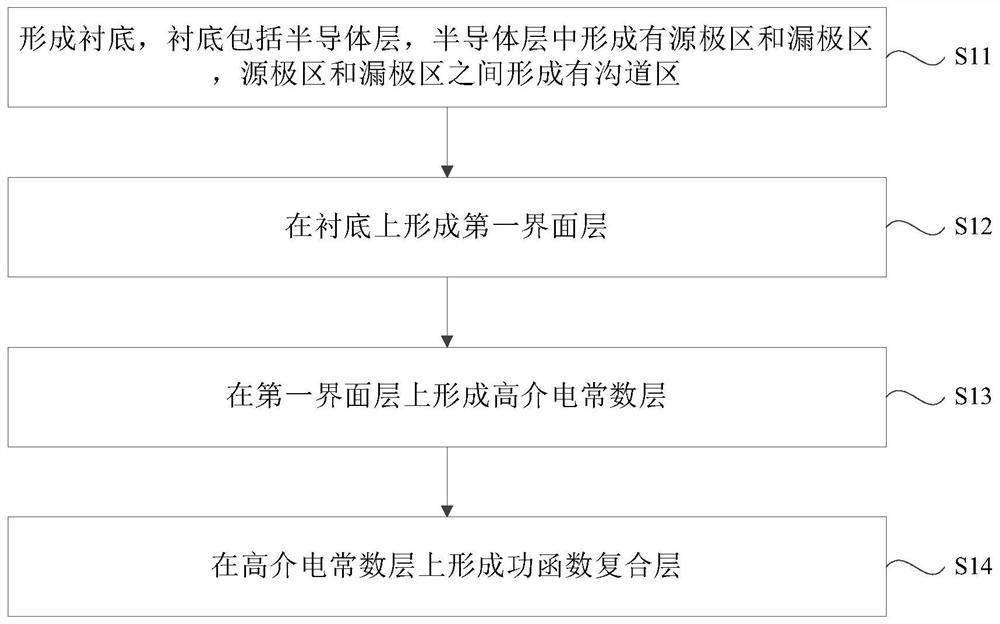

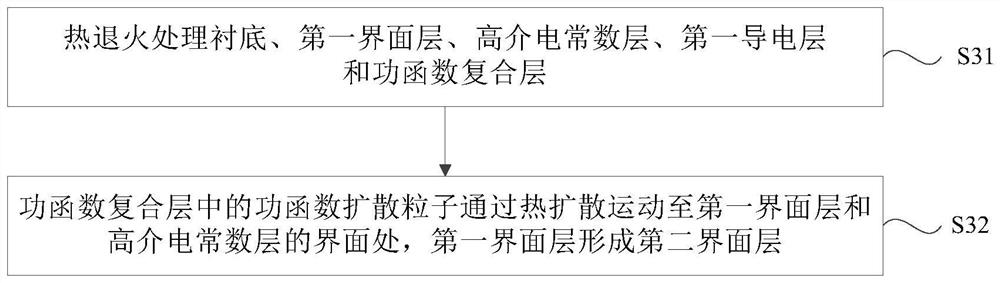

Method used

Image

Examples

Embodiment Construction

[0078] During the actual research process, the inventors of the present application found that when using HKMG technology to manufacture transistors, the heat treatment process and heat treatment annealing process are generally completed in a heat treatment furnace. An amorphous silicon layer is formed on the surface of the layer, and finally a metal gate is formed. Since the polysilicon sacrificial layer grown through the furnace tube requires a long-term high-temperature growth process, this process will generate a large thermal budget, resulting in a decrease in the amount of heat reserved for the work function adjustment process, resulting in the work function adjustment process. , the work function diffusion particles cannot obtain enough energy to diffuse to the predetermined layer position, so that the work function adjustment process cannot be completed. Moreover, in the process of growing the polysilicon sacrificial layer in the furnace tube, the high temperature proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com