High-temperature cooking type medium-resistant solvent-free double-component polyurethane adhesive and preparation method thereof

A two-component polyurethane, high-temperature cooking technology, applied in the technical field of C08G18/42, can solve the problems of not being able to catch up with the development of solvent-free polyurethane laminating adhesive, limited scope of application, production efficiency, and uneven drying of laminating adhesive. , to improve hydrophobicity and solvent resistance, reduce VOC emissions, improve hydrolysis resistance and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

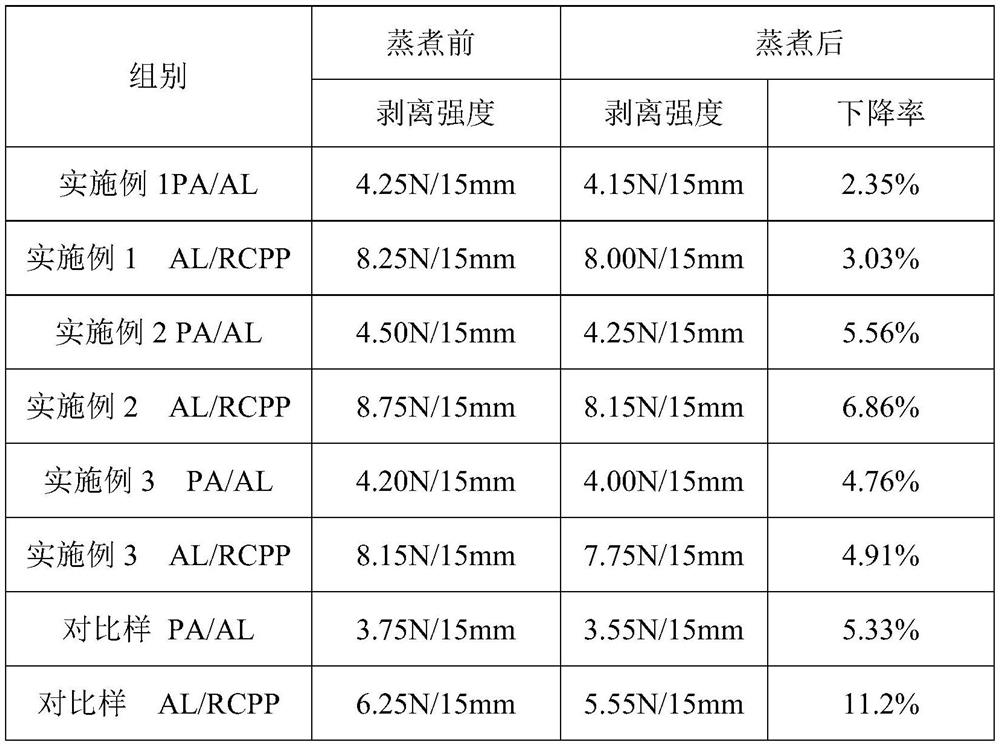

Examples

Embodiment 1

[0044] The present embodiment proposes a high-temperature cooking type medium-resistance solvent-free two-component polyurethane adhesive and a preparation method, wherein the A component includes, by weight, 60 kg of diphenylmethane diisocyanate, 14 kg of polycaprolactone polyol, 26kg of polycarbonate diol; B component by weight, including 60kg of dimer acid modified polyester polyol, 7kg of isocyanate, 3kg of chain extender, 1kg of leveling agent, 0.05kg of catalyst, 30kg Polycarbonate diol.

[0045] The molecular weight of the polycarbonate diol in the A component is 500, and the molecular weight of the polycaprolactone polyol is 1000.

[0046] The isocyanate in the B component is carbodiimide-modified diphenylmethane diisocyanate, the chain extender is neopentyl glycol, the leveling agent is an acrylate compound, and the catalyst is bismuth neodecanoate; polycarbonate; The molecular weight of the diol is 500.

[0047] The preparation method is as follows:

[0048] Compo...

Embodiment 2

[0059] This embodiment proposes a high-temperature cooking type medium-resistance solvent-free two-component polyurethane adhesive and a preparation method, wherein the A component includes, by weight, 40 kg of diphenylmethane diisocyanate and 15 kg of carbodiimide-modified diisocyanate. Phenylmethane diisocyanate, 16 kg of polycaprolactone polyol, 29 kg of polycarbonate diol; component B, by weight, includes 58 kg of dimer acid-modified polyester polyol, 5 kg of isocyanate, 3 kg of expanded Chain agent, 0.5kg leveling agent, 0.05kg catalyst, 34kg polycarbonate diol.

[0060] The molecular weight of the polycarbonate diol in the A component is 1000, and the molecular weight of the polycaprolactone polyol is 1000.

[0061] The isocyanate in the B component is carbodiimide-modified diphenylmethane diisocyanate, the chain extender is neopentyl glycol, the leveling agent is an acrylate compound, and the catalyst is zinc neodecanoate; polycarbonate; The molecular weight of the dio...

Embodiment 3

[0074] This embodiment proposes a high-temperature cooking type medium-resistance solvent-free two-component polyurethane adhesive and a preparation method, wherein the A component, by weight, includes 51 kg of diphenylmethane diisocyanate, 6 kg of isophorone diisocyanate, 10kg of polycaprolactone polyol, 33kg of polycarbonate diol; B component by weight, including 60kg of dimer acid modified polyester polyol, 6kg of isocyanate, 4kg of chain extender, 0.5kg of Leveling agent, 0.05 kg of catalyst, 30 kg of polycarbonate diol.

[0075] The polycarbonate diol in the A component includes a compound material of polycarbonate diol with a molecular weight of 500 and a molecular weight of 1000, the mass ratio is 5:6, and the molecular weight of the polycaprolactone polyol is 2000.

[0076] The isocyanate in the B component is carbodiimide-modified diphenylmethane diisocyanate, the chain extender is diethylene glycol, the leveling agent is an acrylate compound, and the polycarbonate di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com