Shape memory phenolic foam and preparation method thereof

A phenolic foam and memory technology, applied in the field of shape memory polymer synthesis, can solve the problems of no shape memory performance, poor mechanical properties of phenolic resin, high brittleness, etc., and achieve high shape fixation rate, high shape recovery rate, and shape recovery rate The effect of speed and deformation ability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] Another embodiment of the present invention provides the above-mentioned preparation method of shape memory phenolic foam, comprising the following steps:

[0060] S1, add diisocyanate to the resole phenolic resin, and mix uniformly to obtain solution one;

[0061] S2, add solidifying agent and foaming agent successively in described solution one, mix homogeneously, obtain solution two;

[0062] S3, remove the impurity in described solution two, then add surfactant, mix homogeneously, obtain solution three;

[0063] S4. Pour the solution 3 into a preheated mold, heat and solidify, and then demold to obtain a shape memory phenolic foam.

[0064] The preparation method of the shape-memory phenolic foam has the same advantages as the above-mentioned shape-memory phenolic foam relative to the prior art, which is not repeated here. In addition, the preparation method of the shape-memory phenolic foam provided by the present invention has simple process and easy-to-obtain r...

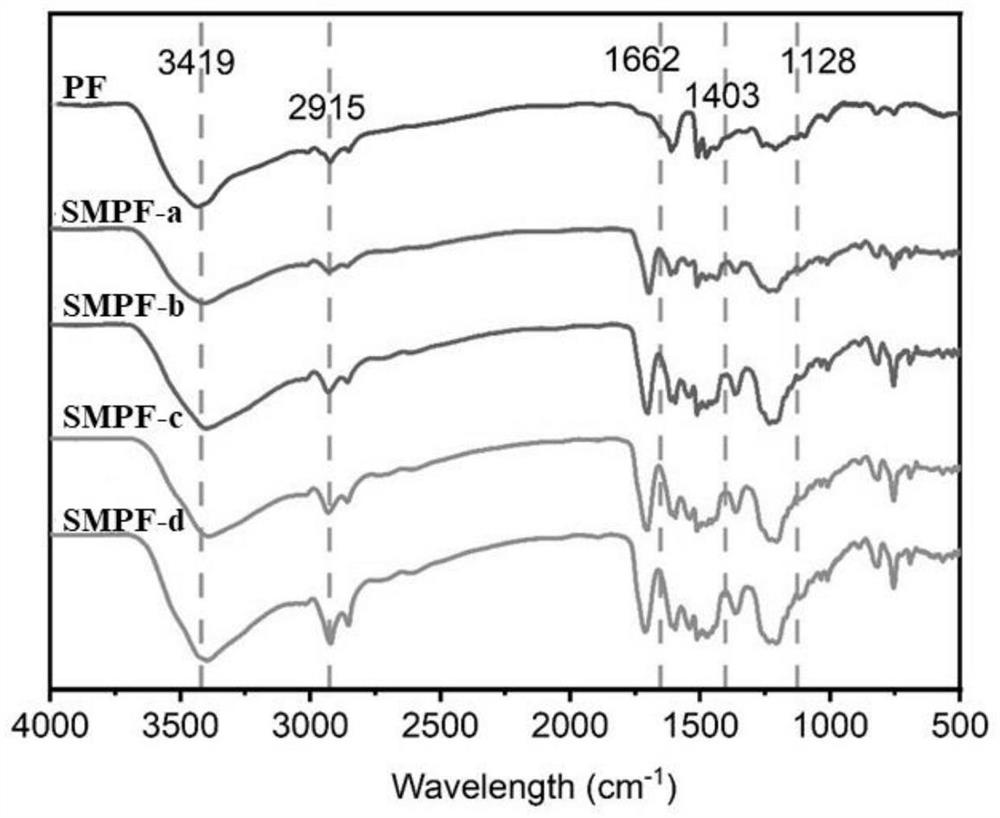

Embodiment 1

[0070] A shape memory phenolic foam, comprising 100 parts of resole phenolic resin, 15-30 parts of hexamethylene diisocyanate toughening agent, 10 parts of phosphoric acid curing agent, 5 parts of isopentane foaming agent, polysorbate-80 surface 8 servings of active agent. Under the aforementioned material ratio, the mass fraction of the toughening agent was adjusted to 15 parts, 20 parts, 25 parts, and 30 parts respectively, and the prepared shape memory phenolic foams were named as SMPF-a, SMPF-b, SMPF-c and SMPF-c. SMPF-d.

[0071] The preparation method of above-mentioned shape memory phenolic foam, comprises the steps:

[0072] S1, add diisocyanate to the resole phenolic resin, and mix uniformly to obtain solution one;

[0073] Wherein, the preparation method of the resole phenolic resin includes: drying the resole phenolic solution in a vacuum drying oven at 60° C. for 40 minutes, and removing impurities such as water and a small amount of ethanol in the resole phenoli...

Embodiment 2

[0080]A shape memory phenolic foam, comprising 100 parts of resole phenolic resin, 30 parts of diphenylmethane diisocyanate as a toughening agent, 10 parts of p-toluenesulfonic acid curing agent, 6 parts of n-hexane foaming agent, polysorbate-80 10 parts of surfactant; the preparation method is basically the same as that of Example 1, except that solution 3 is poured into molds preheated to 75°C, 80°C, 85°C, and 90°C for subsequent curing reaction, and the prepared shape The memory phenolic foams were named SMPF1, SMPF2, SMPF3 and SMPF4 in turn.

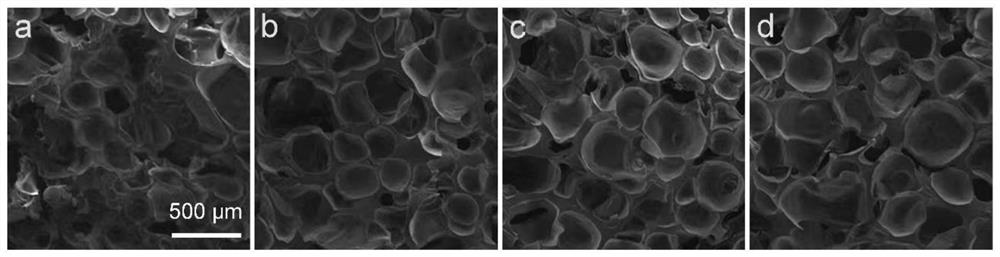

[0081] image 3 The scanning electron microscope image of the shape memory phenolic foam prepared in this example is shown, wherein from left to right, a is SMPF1, b is SMPF2, c is SMPF3, and d is SMPF4. As can be seen from the figure, SMPF1 has a cell diameter of 140-190 μm, SMPF2 has a cell diameter of 170-260 μm, SMPF3 has a cell diameter of 240-310 μm, and SMPF4 has a cell diameter of 290-420 μm. In this example, the control of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com