Soldering flux for wave soldering and manufacturing method thereof

A flux and wave soldering technology, which is applied in the direction of welding equipment, manufacturing tools, welding media, etc., can solve the problems of unfavorable subsequent use of electronic products, poor soldering effect, and increased residual corrosion, so as to ensure activation stability and reduce corrosion , to promote the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

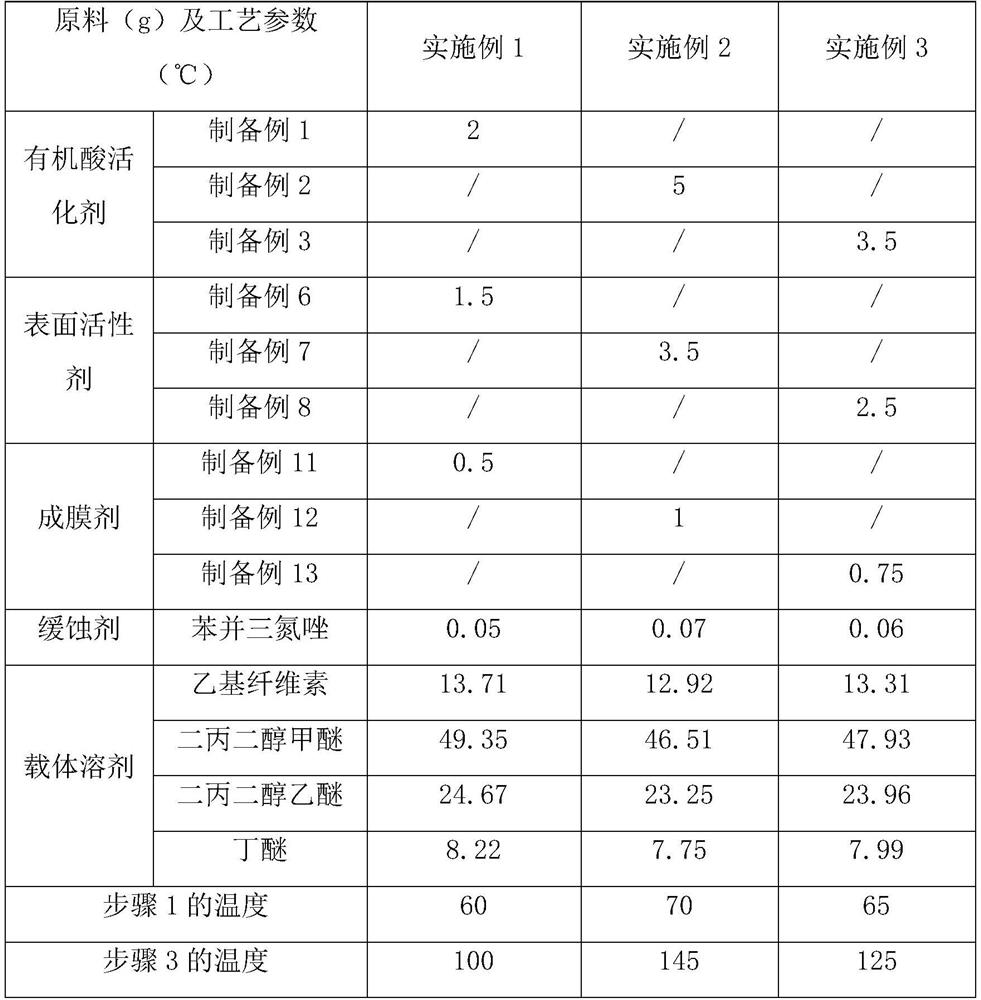

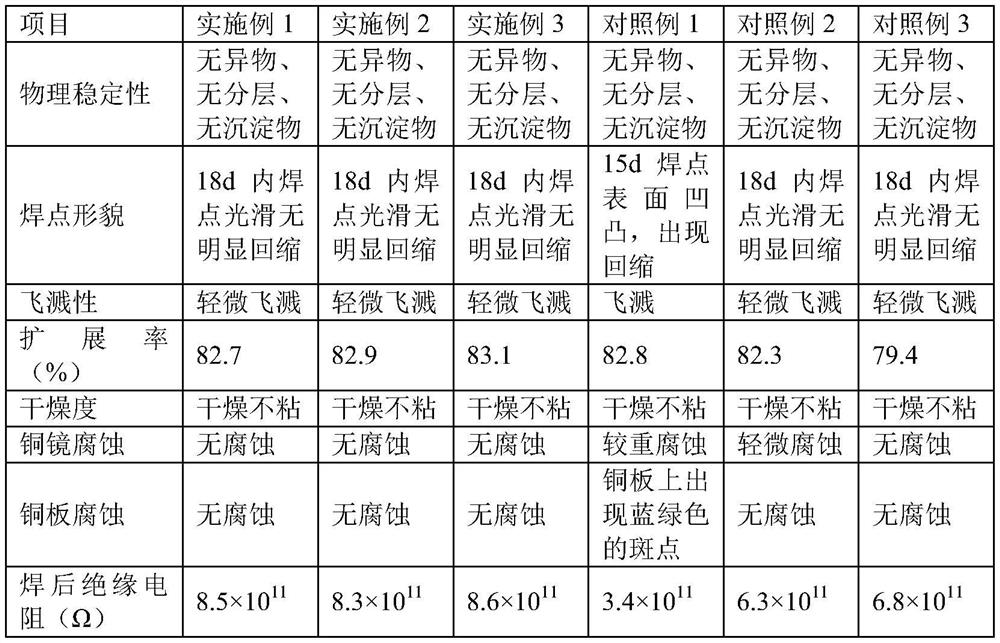

Examples

preparation example 1

[0038] This preparation example discloses a preparation method of an organic acid activator, which specifically includes:

[0039] 5 g of succinic acid and 5 g of adipic acid were added to a mixer, and the mixture was stirred for 5 min at normal temperature and a rotating speed of 70 r / min to obtain an organic acid activator.

preparation example 2

[0041] This preparation example discloses a preparation method of an organic acid activator, which specifically includes:

[0042] 3 g of adipic acid, 4 g of malic acid and 3 g of sebacic acid were added to the mixer, and the mixture was stirred for 7 min at normal temperature and a rotating speed of 70 r / min to obtain an organic acid activator.

preparation example 3

[0044] This preparation example discloses a preparation method of an organic acid activator, which specifically includes:

[0045] Add 2.5 g of succinic acid, 2.5 g of adipic acid, 2.5 g of malic acid and 2.5 g of sebacic acid into the mixer, and stir for 10 min at room temperature and under the conditions of a rotating speed of 70 r / min to obtain an organic acid activator .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com