Battery module and battery pack thermal management device and system

A technology for battery modules and battery packs, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of safe heat transfer medium leakage, large flow resistance of heat transfer medium, and reduced heat transfer efficiency, etc., to improve safety. , The effect of improving temperature uniformity and high energy storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 of the present invention first provides a battery module, which aims to solve the problem that when the existing battery module adopts a water cooling solution, the flow resistance of the heat transfer medium in the cooling flat tube is too large, and there is a certain safety hazard after leakage occurs. question.

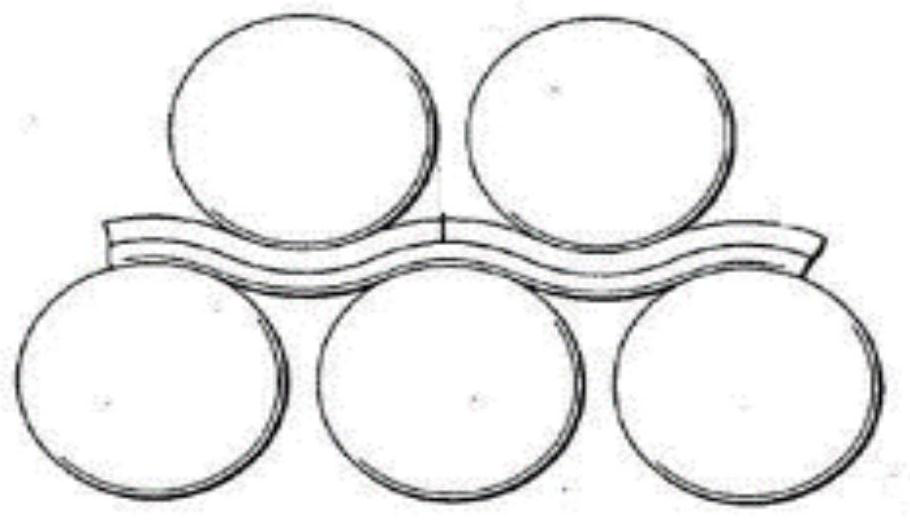

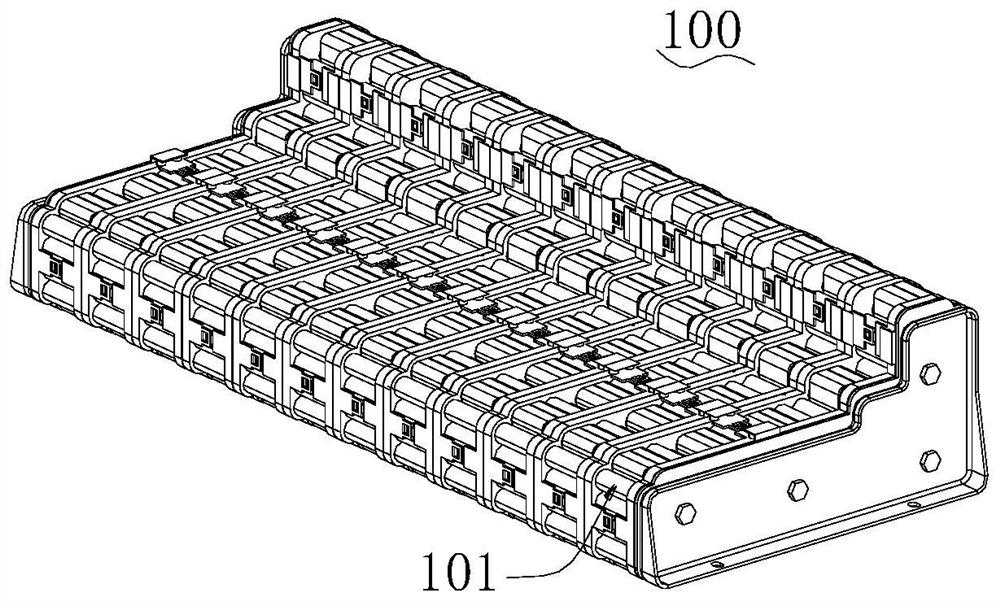

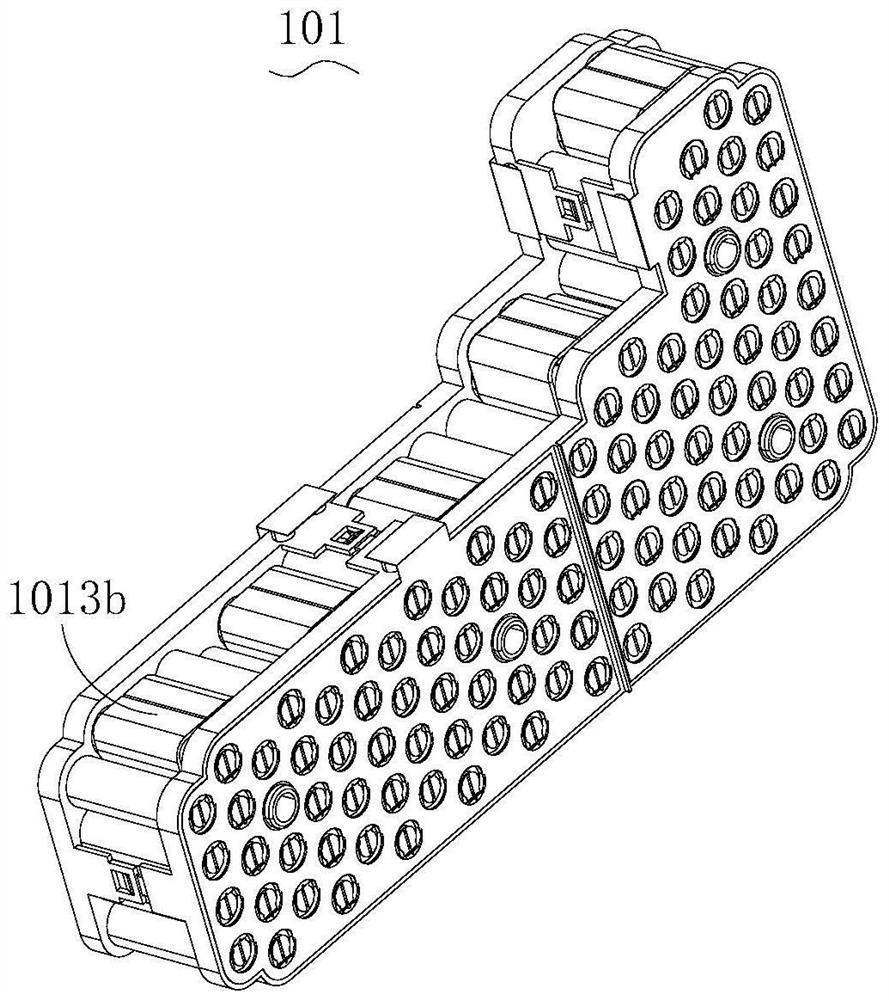

[0045] Please refer to Figure 2 to Figure 8 , Figure 2 to Figure 8 An embodiment of the battery module 100 provided by the present invention is shown. The battery module 100 includes a plurality of battery packs 101 that are closely arranged and connected to each other. The battery pack 101 includes a plurality of battery cells 1011 arranged in a staggered or parallel arrangement. . The battery cells 1011 mentioned above can be any of circular batteries, square batteries, heterosexual batteries, and optionally cylindrical batteries; the battery cells 1011 are stacked and combined into corresponding battery packs 101 .

[0046] see Figure...

Embodiment 2

[0063] see Figure 9 , Based on the battery module 100 provided above, the second embodiment of the present invention further provides a battery pack thermal management device 200, the battery pack thermal management device 200 includes:

[0064] At least one battery module 100 as mentioned above;

[0065] The first heat transfer tube 201 is in contact with one side of the heat conducting member 1013;

[0066] The second heat transfer tube 202 is in contact with the other side of the heat conducting member 1013;

[0067] The first heat transfer tube 201 is in contact with the heat collecting end on the upper side of the heat conducting member 1013 to dissipate heat to the cell unit 1011; 1011 is preheated, so that the battery cell 1011 is at a normal working temperature, so as to avoid the battery running at a low temperature and improve the use efficiency of the battery.

[0068] It should be noted that the “heat collecting end” as defined in the embodiments of the present...

Embodiment 3

[0077]Embodiment 3 of the present invention further provides a battery pack thermal management system, including the above-mentioned battery pack thermal management device 200, the system may further include a controller, and the controller can read a precoded program to execute corresponding instructions, wherein the control The device is configured as:

[0078] In the first mode, the first heat transfer pipe 201 is controlled to pass through the heat transfer medium to dissipate heat to the battery module 100;

[0079] In the second mode, the temperature of the second heat transfer tube 202 is controlled to preheat the battery module 100 .

[0080] The first mode includes when the battery module 100 in the vehicle needs to be dissipated, such as when the vehicle is running, and the second mode includes when the battery module 100 of the vehicle needs to be warmed up, such as when the vehicle is cold started.

[0081] In this system, a sensor can be provided on the end face ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com