Argyrodite type sulfide electrolyte and preparation method thereof

A technology of sulfide electrolyte and silver-sulfur-germanium ore, which can be used in circuits, electrical components, secondary batteries, etc., can solve problems such as potential safety hazards, and achieve the effects of enhancing compatibility, high ionic conductivity, and accelerating practical application development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] According to one aspect of the present invention, the present invention proposes an arginine-type sulfide electrolyte and a preparation method thereof. According to an embodiment of the present invention, it includes:

[0030] (1) Prepare raw materials;

[0031] (2) ball mill mixing;

[0032] (3) tableting;

[0033] (4) Quartz tube packaging;

[0034] (5) High temperature sintering treatment in muffle furnace.

[0035] Thus, the present invention prepares a kind of silver-germanite type sulfide solid-state electrolyte Li by ball milling and sintering6+x Zr x P 1- x S 5 PF 6 . The products obtained by the invention have higher ionic conductivity, so that the practical application development of high-performance solid-state batteries can be accelerated.

[0036] According to a specific embodiment of the present invention, the Li source used in the above-mentioned preparation of raw materials may be LiPF 6 Thereby, an arginite-type sulfide solid-state electrolyte...

Embodiment 1

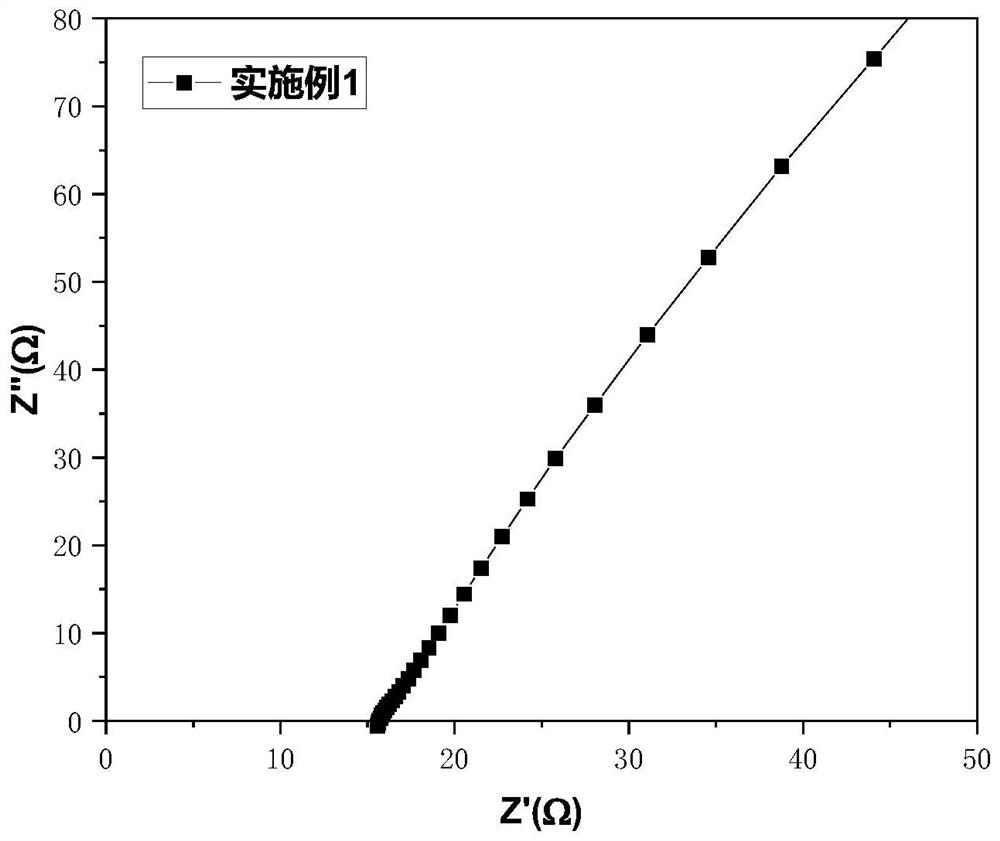

[0049] Weigh the pure reagent ZrS according to the required stoichiometric ratio 0.1:0.95:2:5.05 2 , P 2 S 5 , LiPF 6 and Li 2 S hand milled for 25 minutes after mixing. Put it into a zirconia ball milling jar, add zirconia ball milling at a mass ratio of 1:50, set the speed of the ball mill to 370 rpm, and set the ball milling time to 40 hours. Then scrape off the samples attached to the jar wall, and sieve them with a 1000-mesh sieve. A well-mixed precursor can be obtained. Then tablet (diameter 12mm) was pressed with a pressure of 450MPa. Load the quartz tube into the sealed tube. The temperature was raised to 475 °C at a rate of 1 / min, kept for 8 h, and Li was obtained after cooling. 6.05 Zr 0.05 P 0.95 S 5 PF 6 Solid electrolyte powder. It can be found from the XRD that the solid electrolyte powder prepared by this method is a sapphire-type cubic phase, with good crystal form and high purity. The solid electrolyte powder was pressed under a pressure of 580Mpa...

Embodiment 2

[0052] Weigh the pure reagent ZrS according to the required stoichiometric ratio of 0.2:0.9:2:5.1 2 , P 2 S 5 , LiPF 6 and Li 2 S hand milled for 25 minutes after mixing. Put it into a zirconia ball milling jar, add zirconia ball milling at a mass ratio of 1:50, set the speed of the ball mill to 370 rpm, and set the ball milling time to 40 hours. Then scrape off the samples attached to the jar wall, and sieve them with a 1000-mesh sieve. A well-mixed precursor can be obtained. Then tablet (diameter 12mm) was pressed with a pressure of 450MPa. Load the quartz tube into the sealed tube. The temperature was raised to 475 °C at a rate of 1 / min, kept for 8 h, and Li was obtained after cooling. 6.1 Zr 0.1 P 0.9 S 5 PF 6 Solid electrolyte powder. It can be found from the XRD that the solid electrolyte powder prepared by this method is a sapphire-type cubic phase, with good crystal form and high purity. The solid electrolyte powder was pressed under a pressure of 580Mpa a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com