Needle coke regulated and controlled by transition metal as well as preparation and application of needle coke

A transition metal and transition metal salt technology, which is applied in the preparation/purification of carbon, structural parts, electrical components, etc., can solve the problems of reduced cycle capacity of electrode materials, increase of carbon materials, and reduced material conductivity, etc., to achieve excellent rate performance and cycle stability, improve the deintercalation process, and increase the effect of active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

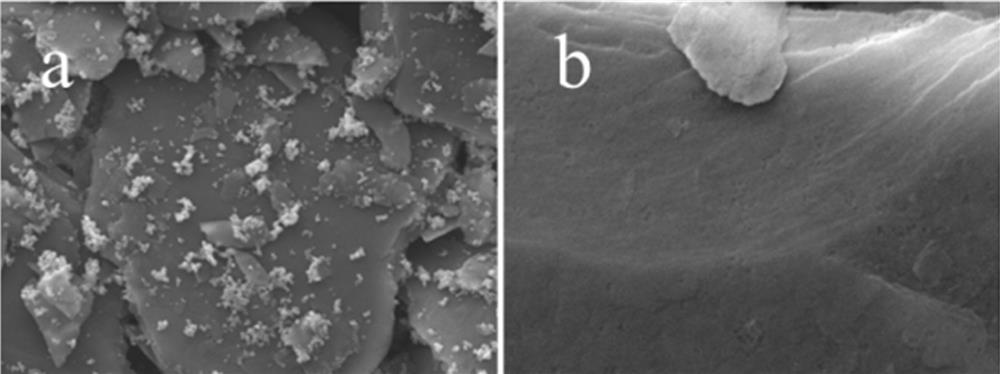

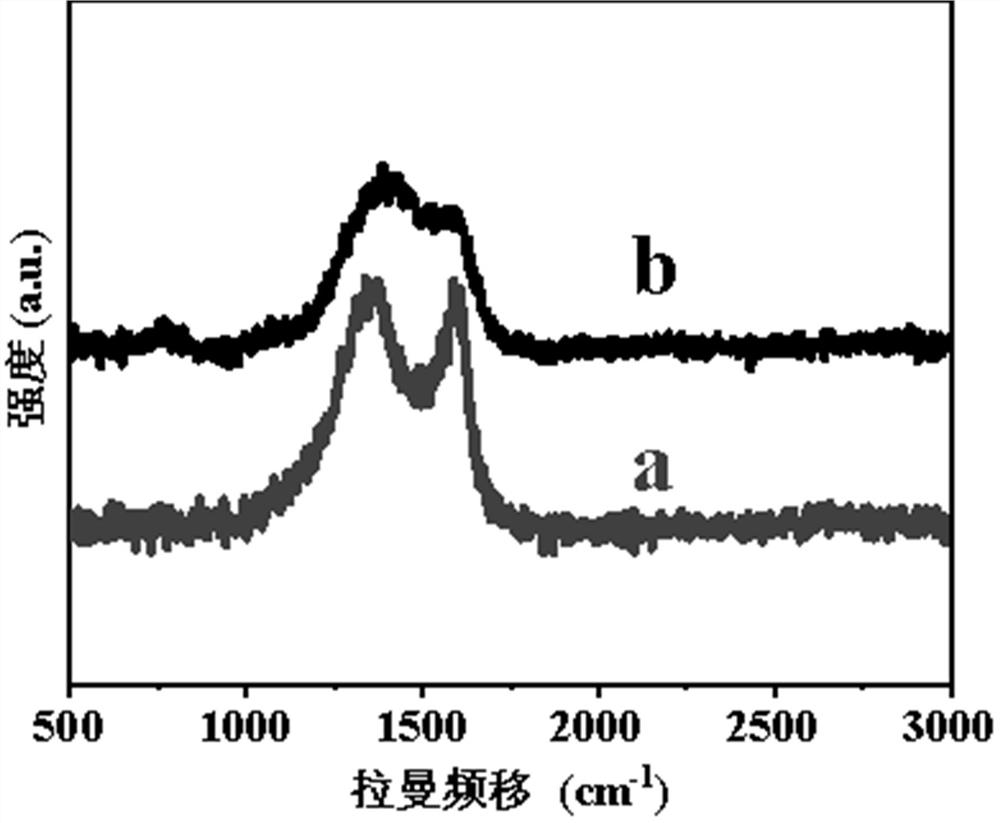

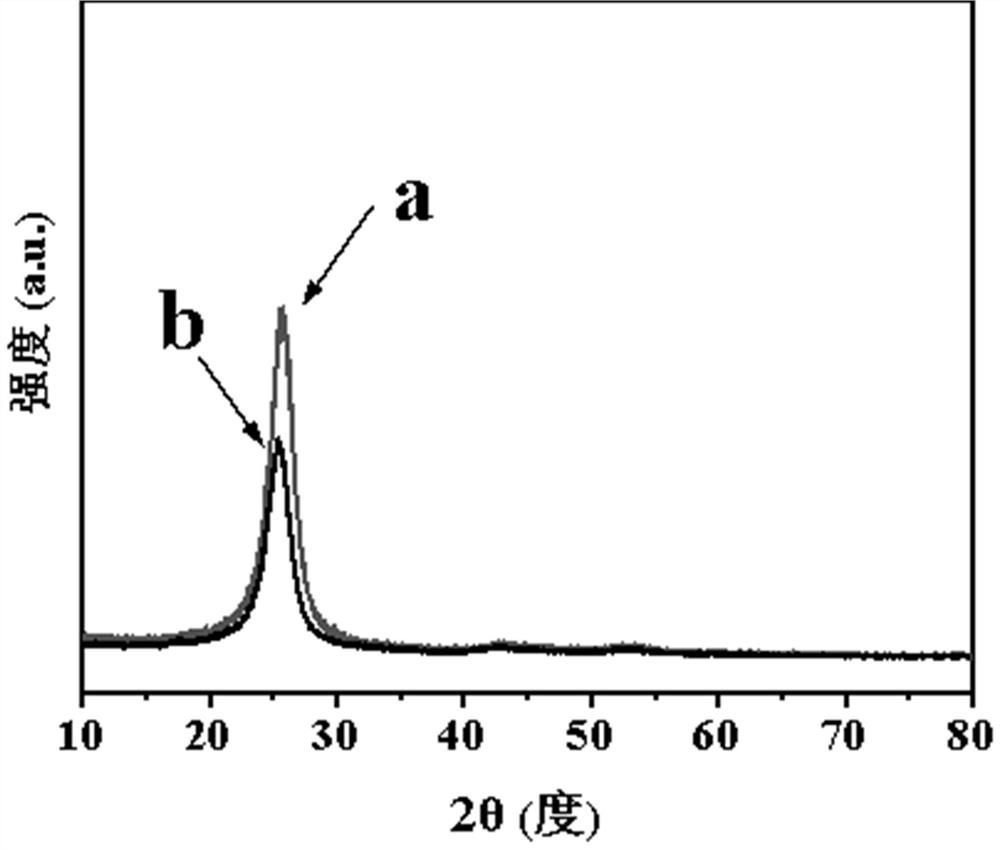

[0030] The industrial-grade needle coke is passed through a mixture of hydrofluoric acid and concentrated hydrochloric acid with a volume ratio of 1:4, and then the ash and other impurities contained therein are removed to obtain pure needle coke. The specific work is 2 g needles. The coke was placed in 200 mL with a volume ratio of 75% H 2 O 2 In the reaction process, the reaction was stirred in a water bath at a temperature of 50 °C for 6 h, followed by suction filtration and drying at 60 °C for 12 h under vacuum conditions to obtain the activated needle coke.

[0031] 0.5 g of the activated needle coke obtained in the previous step and 1 g of powdered Fe(NO 3 ) 3 9H 2 O was placed in 80 mL of deionized water, stirred for 1 h and sonicated for 2 h, then the homogeneous mixture was put into a 100 mL stainless steel hydrothermal kettle, and the temperature was set at 180 °C and maintained for 12 h. After the reaction, suction filtration and Placed in a vacuum drying oven ...

Embodiment 2

[0034] The industrial-grade needle coke is passed through a mixture of hydrofluoric acid and concentrated hydrochloric acid with a volume ratio of 1:3, and then the ash and other impurities contained therein are removed to obtain pure needle coke. The specific work is 1 g needle. The coke was placed in 120 mL with a volume ratio of 75% H 2 O 2 In the reaction process, the reaction was stirred in a water bath at a temperature of 50 °C for 6 h, followed by suction filtration and drying at 60 °C for 12 h under vacuum conditions to obtain the activated needle coke.

[0035] 0.25 g needle coke and 0.25 g powder Fe(NO 3 ) 3 9H 2 O was placed in 80 mL of deionized water, stirred for 1 h and sonicated for 2 h, then the homogeneous mixture was put into a 100 mL stainless steel hydrothermal kettle, and the temperature was set at 180 °C and maintained for 12 h. After the reaction, suction filtration and Placed in a vacuum drying oven at 60 °C for drying; then the dried mixture was c...

Embodiment 3

[0038] The industrial-grade needle coke is passed through a mixture of hydrofluoric acid and concentrated hydrochloric acid with a volume ratio of 1:3, and then the ash and other impurities contained therein are removed to obtain pure needle coke. The specific work is 1 g needle. The coke was placed in 160 mL with a volume ratio of 75% H 2 O 2 In the reaction process, the reaction was stirred in a water bath at a temperature of 50 °C for 6 h, followed by suction filtration and drying at 60 °C for 12 h under vacuum conditions to obtain the activated needle coke.

[0039] 0.5 g of activated needle coke and 1.2 g of powdered Co(NO 3 ) 3 6H 2 O was placed in 80 mL of deionized water, stirred for 1 h and sonicated for 2 h, then the homogeneous mixture was put into a 100 mL stainless steel hydrothermal kettle, and the temperature was set at 180 °C and maintained for 12 h. After the reaction, suction filtration and The dried mixture was calcined in a tube furnace at 500°C and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com