Method for determining mercury and arsenic in briquette coal based on hydrothermal synthesis reaction kettle digestion briquette coal-atomic fluorescence spectrometry

A technique of atomic fluorescence spectroscopy and hydrothermal synthesis, which is applied in the field of liquid phase chemistry, can solve the problems of out-of-control reactions, difficulties in popularization, and long time for acid removal, and achieve mild and easy-to-control conditions, cheap instruments, and guaranteed accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

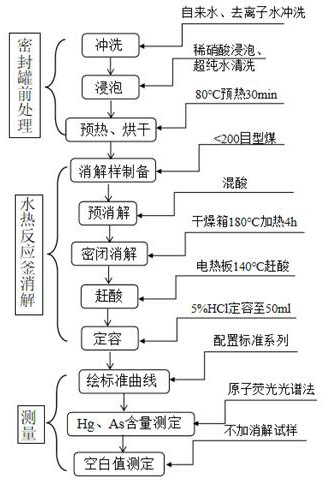

[0046] like figure 1 As shown, a method for determining mercury and arsenic in briquette based on hydrothermal synthesis reactor digestion of briquette-atomic fluorescence spectrometry, comprising the following steps:

[0047] (1) Pretreatment: Rinse the PTFE sealed tank of the hydrothermal synthesis reactor and the container used repeatedly with tap water and deionized water, and gently brush the inner wall with a soft cotton brush until it is clean, and place it in a mass concentration of 10%. Soak in the nitric acid solution overnight, take it out, wash it with ultrapure water three times, wash off the surface nitric acid, place the sealed tank in a blast drying oven at 80°C, dry and preheat for 30min, and set aside for later use;

[0048] (2) Pretreatment of briquette:

[0049] Weigh an appropriate amount of briquette at 105°C, dry to constant weight, and grind it through a 200-mesh sieve;

[0050] (3) Pre-digestion: Weigh 50mg of briquette (accurate to 0.0002g) and plac...

Embodiment 2

[0070] Others are the same as in Example 1, except that the biomass in the composite binder is different. In this example, the biomass is corn stover, and the obtained composite binder B is formed with pulverized coal to prepare briquette B, which is used as a digestion sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com