UV-cured conductive graphene coating and construction method thereof

A technology of conductive graphite and construction method, applied in conductive coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc., can solve the problems of graphene being difficult to agglomerate, hindering graphene agglomeration, and graphene being easy to agglomerate, so as to avoid agglomeration and precipitation. , The effect of easy curing and convenient construction

Active Publication Date: 2022-07-08

浙江艾特普科技有限公司

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The present invention provides a UV curing conductive paint in order to overcome the problem that graphene is easy to agglomerate in the graphene conductive paint in the prior art and the improvement of paint performance is limited. The graphene coating and its construction method, through the compounding of each light-curing monomer and polyurethane acrylate resin, the coating has UV curing performance, and the graphene conductive filler can float between layers, so that it can be added during the construction process. The current adjusts the dispersion continuity of the graphene conductive filler in the coating, hinders the agglomeration of graphene, ensures the laying effect of the graphene conductive coating and facilitates large-scale construction, and graphene is not easy to agglomerate

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

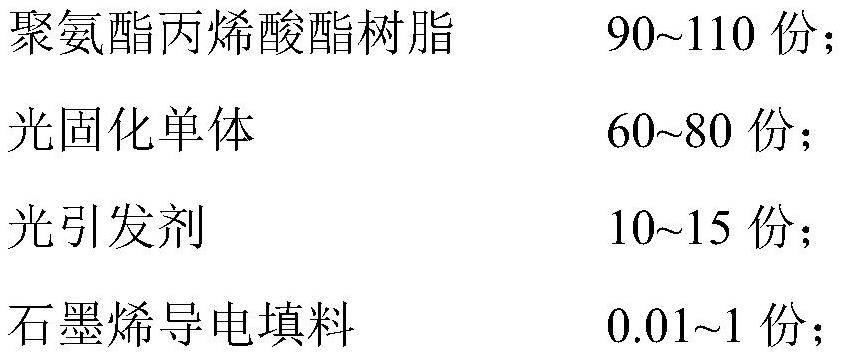

[0039] A UV-curable conductive graphene coating, in parts by weight, the components include:

[0040]

Embodiment 2

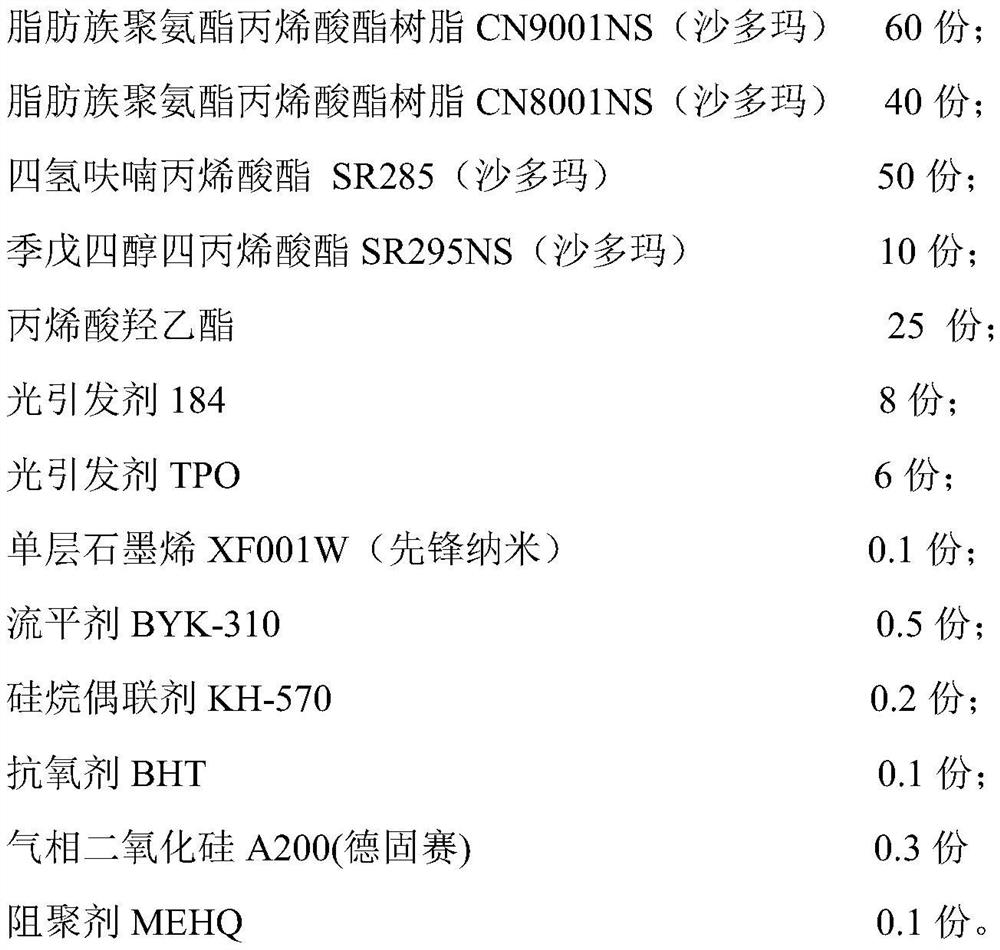

[0042] A UV-curable conductive graphene coating, in parts by weight, the components include:

[0043]

[0044]

Embodiment 3

[0046] A UV-curable conductive graphene coating, in parts by weight, the components include:

[0047]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a UV-curable conductive graphene coating and a construction method thereof, and the UV-curable conductive graphene coating comprises the following components in parts by weight: 90-110 parts of polyurethane acrylate resin, 60-80 parts of a photocuring monomer, 10-15 parts of a photoinitiator, 0.01-1 part of a graphene conductive filler, and 0.5-2 parts of an auxiliary agent. Wherein the photocuring monomer is prepared from the following components in parts by weight: 45 to 55 parts of tetrahydrofuran acrylate, 10 to 30 parts of hydroxyethyl acrylate and 5 to 15 parts of pentaerythritol tetraacrylate. According to the invention, through compounding of the photocuring monomers and the polyurethane acrylate resin, the coating has UV curing performance, and the conductive filler can float between layers, so that the dispersion continuity of the conductive filler in the coating and the uniformity of the distance between the conductive filler and the lower layer can be adjusted through impressed current in the construction process; and the laying effect of the conductive coating is ensured, and large-area construction is easy.

Description

technical field [0001] The invention relates to the field of conductive coatings, in particular to a UV-cured conductive graphene coating and a construction method thereof. Background technique [0002] Graphene is a two-dimensional honeycomb carbon material composed of carbon atoms arranged in hexagons. The carbon atoms are formed by sp2 hybridization, and their structure is very stable. The special structure of graphene makes it have many excellent properties: graphene is the hardest substance found so far, and has excellent mechanical properties, outstanding thermal conductivity, up to 3000W / (m K); in addition, Graphene also has good electrical conductivity, and its electron mobility can be as high as 20000CM at room temperature 2 / (V·s). [0003] Graphene is added to the coating as a reinforcing material, in addition to enhancing the strength of the coating, it can also make the coating have excellent properties such as anti-corrosion, heat generation, electrical cond...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D175/14C09D5/24C09D5/08B05D5/12B05D7/00B05D7/24B05D3/06B05D1/36

CPCC09D175/14C09D5/24C09D5/08B05D5/12B05D7/542B05D7/24B05D3/067B05D1/36C08K2201/001C08L75/14C08K3/041

Inventor 卢鹏飞姜山姜小扣杨炜煌

Owner 浙江艾特普科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com