Waste solidified treatment device for drilling

A drilling waste solidification treatment technology, applied in sludge treatment, solid waste removal, water/sludge/sewage treatment, etc., can solve problems such as unstable curing effect, high amount of curing agent added, and high labor intensity , to achieve the effect of easy curing, stable curing effect and high degree of mechanization

Inactive Publication Date: 2010-11-10

SICHUAN RENZHI PETROCHEMICAL TECHNOLOGY CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Correspondingly, there are problems such as high amount of curing agent, unstable curing effect, easy occurrence of leachate in the cured body, which cannot meet environmental protection requirements, inconvenient treatment of the cured body, etc., and the existing curing treatment device is simple, labor-intensive, and the processing while drilling causes relatively large pollution

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

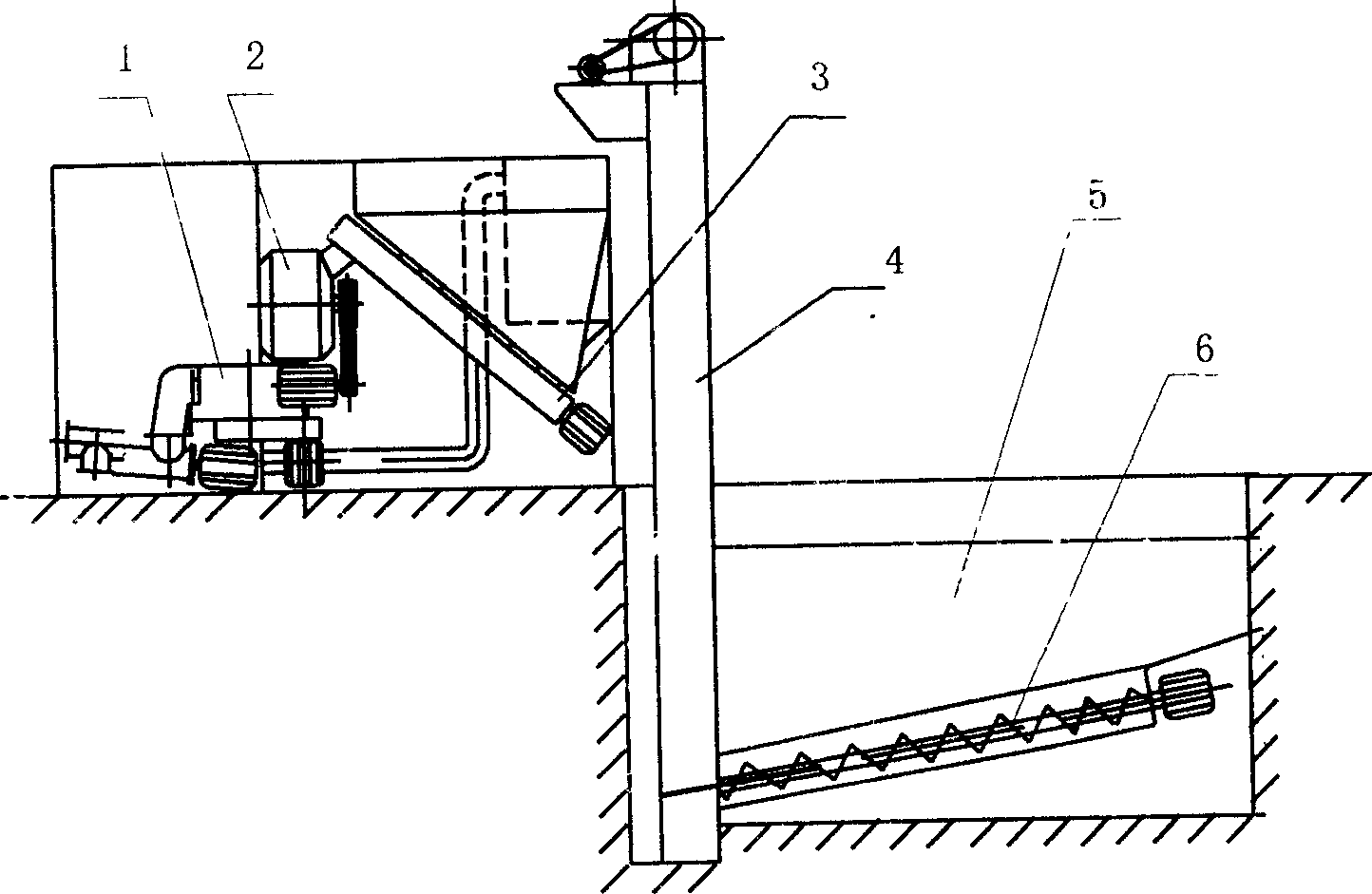

The invention relates to a method for treating drilling wastes in petroleum and gas exploitation, especially a solidification treatment method and an apparatus thereof. The treatment method adopts delivering the drilling wastes to a high speed disintegrator to smash, at the same time spraying firming agent to the high speed disintegrator. The apparatus comprises a delivery conveyor within a receiving bucket, a bucket elevator, a feeding spiral conveyer, a high speed disintegrator and a firming agent conveyer. The invention smashes wastes to form numerous small particle, after that, carries out physico-chemical reaction with the firming agent, and packages the small particle. Accordingly, the invention has good solidifying effect correspondingly, can reduce firming agent application amount, wherein the solidified body extract will not pollute the environment. Meanwhile, the apparatus of the invention with high mechanization degree, may form automatic integration, is convenient for achieving solidification treatment along with the drilling process without generating environment pollution.

Description

Drilling waste solidification treatment device technical field The invention relates to a treatment device for drilling waste in oil and natural gas exploitation, especially a solidification treatment device. Background technique With the massive exploitation of oil and gas, the disposal of drilling waste fluid has become a major problem due to serious pollution. At present, centrifuges are generally used for solid-liquid separation in the treatment of drilling waste fluid, and the separated liquid is treated with gel breakers and micro-electrolysis; the separated waste (mainly mud) is solidified by adding a curing agent. The general process of the existing curing treatment is to directly add the curing agent into the waste and stir. Correspondingly, there are problems such as high amount of curing agent, unstable curing effect, easy occurrence of leachate in the cured body, which cannot meet environmental protection requirements, inconvenient treatment of the cured body,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B09B3/00E21B21/06C02F11/00

Inventor 卜文海杨勇续书成夏卫东袁海宋自家汪廷洪

Owner SICHUAN RENZHI PETROCHEMICAL TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com