SiHfOC ceramic microspheres and preparation method thereof

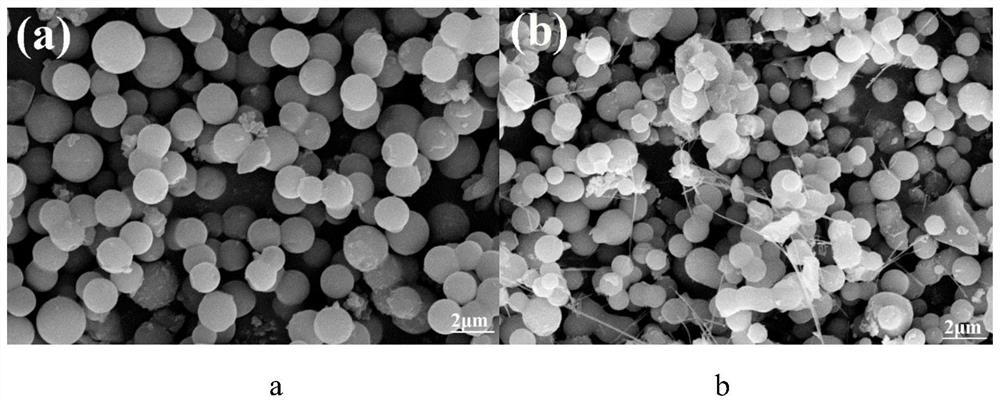

A technology of ceramic microspheres and microspheres, which is applied in the field of ceramic microspheres, can solve problems such as limited applications, and achieve the effect of smooth surface, short preparation cycle and regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

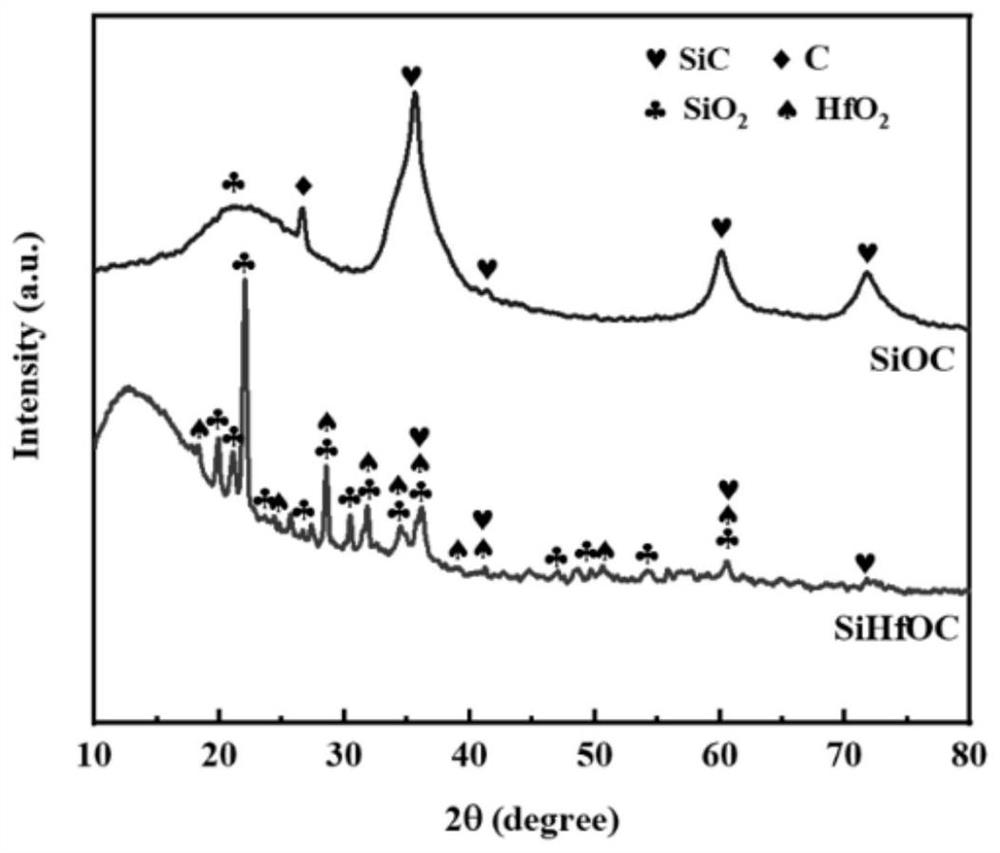

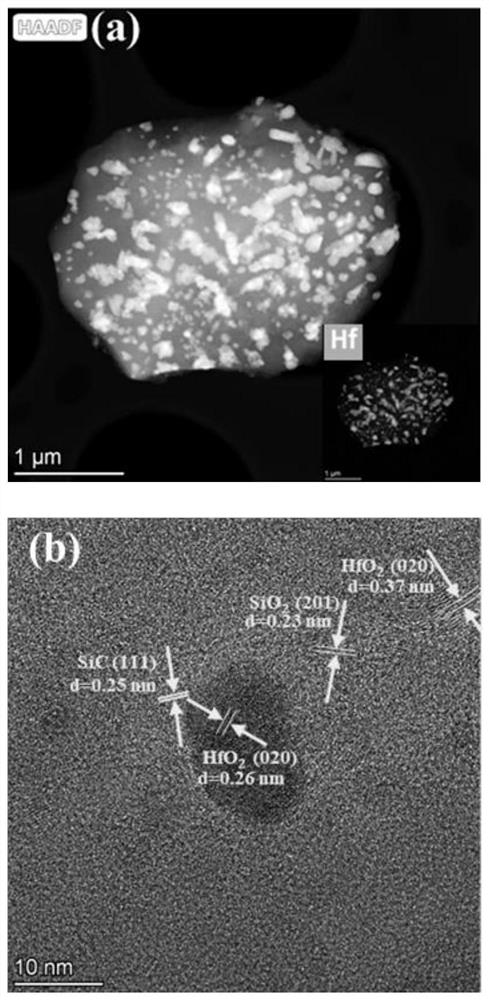

Embodiment 1

[0039] Polysilazane and divinylbenzene with a mass ratio of 2:1 and a certain amount of OP-10 (divinylbenzene: OP-10=1:1) were added dropwise to the pure acetonitrile solution, and then the The above solution was transferred to an ultrasonic cleaner for further mixing with an ultrasonic power of 100W to obtain a homogeneous emulsion system, and then the emulsion was transferred to an autoclave for solidification for 8h, and the solid product was separated by a suction filtration device. Wash several times with deionized water and anhydrous ethanol, and dry in an oven at 80°C;

[0040] The product of step 1 and a certain amount of hafnium acetylacetonate (PSN microspheres: hafnium acetylacetonate = 8:2) were added to the xylene solution for uniform mixing, and then transferred to a three-necked flask to carry out a polymerization reaction at 80 °C, After the reaction, suction filtration, washing and drying are performed to obtain Hf-modified PSN microspheres;

[0041] The prod...

Embodiment 2

[0044] According to the volume ratio of deionized water:acetonitrile=2:8, a mixed solution was prepared and mixed evenly on a magnetic stirrer, and then polysilazane and divinylbenzene with a mass ratio of 2:1 and a certain amount of OP-10 (divinylbenzene: OP-10=1:1) was added dropwise to the above mixed solution, and then the above solution was transferred to an ultrasonic cleaner for further mixing with an ultrasonic power of 100W to obtain a homogeneous emulsion system, and then transferred the emulsion to a high-pressure reactor to solidify for 10 hours, and separated the solid product through a suction filtration device. During the suction filtration process, it was washed several times with deionized water and anhydrous ethanol, and dried in an oven at 80 °C. ;

[0045] The product of step 1 and a certain amount of hafnium acetylacetonate (PSN microspheres: hafnium acetylacetonate = 8:2) were added to the xylene solution for uniform mixing, and then transferred to a thre...

Embodiment 3

[0049] According to the volume ratio of deionized water:acetonitrile=3:7, a mixed solution was prepared and mixed evenly on a magnetic stirrer, and then polysilazane and divinylbenzene with a mass ratio of 2:1 and a certain amount of OP-10 (divinylbenzene: OP-10=1:1) was added dropwise to the above mixed solution, and then the above solution was transferred to an ultrasonic cleaner for further mixing with an ultrasonic power of 100W to obtain a homogeneous emulsion Then the emulsion was transferred to a high-pressure reactor for solidification for 8 hours, and the solid product was separated by a suction filtration device. During the suction filtration process, it was washed several times with deionized water and anhydrous ethanol, and dried in an oven at 80 °C. ;

[0050] The product of step 1 and a certain amount of hafnium acetylacetonate (PSN microspheres: hafnium acetylacetonate = 8:2) were added to the xylene solution for uniform mixing, and then transferred to a three-n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com