LaCeNiO perovskite catalyst with ultra-wide Ni (111) crystal face as well as preparation method and application of LaCeNiO perovskite catalyst

A catalyst and perovskite technology, which is applied in the field of methanation catalyst and its preparation and application, can solve the problems of easy deactivation, and achieve the effects of convenient operation, low preparation temperature and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

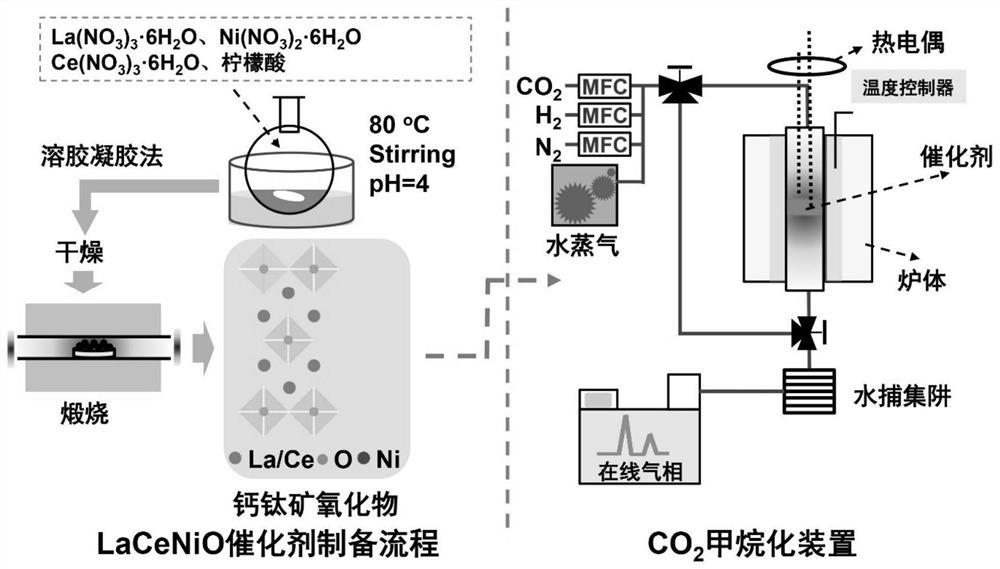

[0040] Preparation of La with La:Ce=2:0 2 NiO 4 perovskite catalyst

[0041] Weigh 2.9863g La (NO 3 ) 3 ·6H 2 O, 0g Ce (NO 3 ) 3 6H 2 O, 1.0027g Ni (NO 3 ) 3 ·6H 2 O, 2.9815g citric acid, add 80mL water to fully dissolve, add ammonia water to adjust the pH of the mixed solution to 4, stir at 80°C, evaporate and concentrate to 20mL gel, take out, fully dry in a blast drying oven at 100°C for 12h to obtain the precursor body. After the precursor was crushed and sieved to 70 mesh, it was put into a muffle furnace, heated to 350°C for 4 hours at a heating rate of 3°C / min, and then calcined at a heating rate of 5°C / min to 600°C for 5 hours. After cooling, take it out, put it into a tube furnace, and pass 50mL / min H 2 Reduced for 1 h to obtain highly dispersed metallic Ni, ultra-wide Ni(111) crystal planes, and La rich in oxygen vacancies 2 NiO 4 perovskite catalysts. Ce 2 NiO 4 STEM and high-resolution transmission images of catalysts such as figure 2 As shown, ...

Embodiment 2

[0043] Preparation of La with La:Ce=1.5:0.5 1.5 Ce 0.5 NiO 4 perovskite catalyst

[0044] Weigh 2.2397g La (NO 3 ) 3 ·6H 2 O, 0.7487g Ce (NO 3 ) 3 ·6H 2 O, 1.0027g Ni (NO 3 ) 3 ·6H 2 O, 2.9815g citric acid, add 80mL water to fully dissolve, add ammonia water to adjust the pH of the mixed solution to 4, stir at 80°C, evaporate and concentrate to 20mL gel, take out, fully dry in a blast drying oven at 100°C for 12h to obtain the precursor body. After the precursor was crushed and sieved to 70 mesh, it was put into a muffle furnace, heated to 350°C for 4 hours at a heating rate of 3°C / min, and then calcined at a heating rate of 5°C / min to 600°C for 5 hours. After cooling, take it out, put it into a tube furnace, and pass 50mL / min H 2 Reduced for 1 h to obtain highly dispersed metallic Ni, ultra-wide Ni(111) crystal planes, and La rich in oxygen vacancies 1.5 Ce 0.5 NiO 4 perovskite catalysts.

Embodiment 3

[0046] Preparation of LaCeNiO with La:Ce=1:1 4 perovskite catalyst

[0047] Weigh 1.4931g La (NO 3 ) 3 ·6H 2 O, 1.4973g Ce (NO 3 ) 3 ·6H 2 O, 1.0027g Ni (NO 3 ) 3 ·6H 2 O, 2.9815g citric acid, add 80mL water to fully dissolve, add ammonia water to adjust the pH of the mixed solution to 4, stir at 80°C, evaporate and concentrate to 20mL gel, take out, fully dry in a blast drying oven at 100°C for 12h to obtain the precursor body. After the precursor was crushed and sieved to 70 mesh, it was put into a muffle furnace, heated to 350°C for 4 hours at a heating rate of 3°C / min, and then calcined at a heating rate of 5°C / min to 600°C for 5 hours. After cooling, take it out, put it into a tube furnace, and pass 50mL / min H 2 Reduction for 1 h to obtain LaCeNiO with highly dispersed metallic Ni, ultra-wide Ni(111) crystal face, and abundant oxygen vacancies 4 perovskite catalysts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com