Laser device

A laser and laser cavity technology, applied in the field of lasers, can solve problems such as output wavelength changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

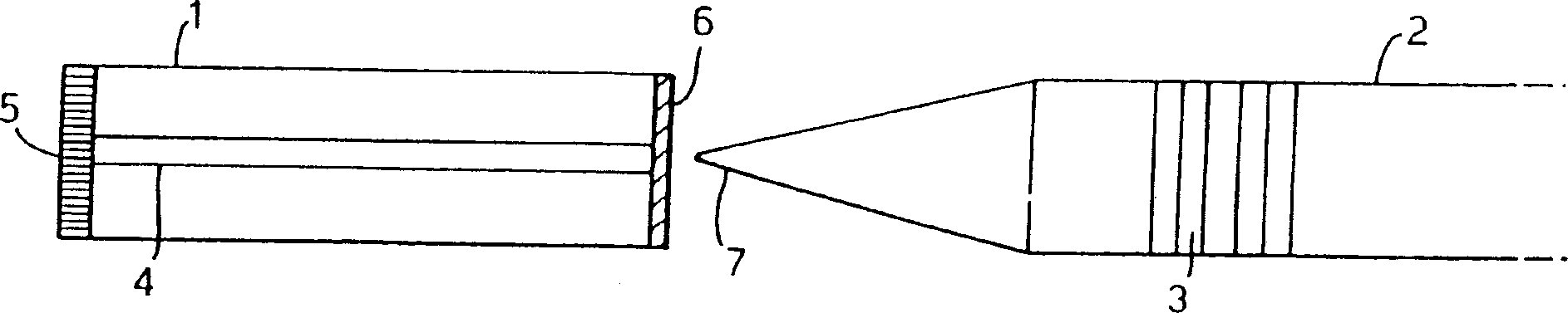

[0032] figure 1 It is a schematic diagram of a prior art fiber grating laser, which includes a semiconductor laser diode 1 aligned with an optical fiber 2 with a grating 3 written in the fiber by ultraviolet light. The semiconductor laser diode 1 comprises an optical waveguide 4 for guiding optical radiation between its rear facet 5 and front facet 6 . The back facet 5 can be plated with a high-reflectivity multi-layer dielectric film, so as to improve its reflectivity in addition to the Fresnel reflection to the semiconductor / air interface. The front flat 6 of the semiconductor laser diode 1 is coated with a multi-layer dielectric anti-reflection film. The optical fiber 2 then includes a tapered fiber lens 7 at its end close to the front facet 6 of the semiconductor laser diode 1 . The laser action characteristics of the fiber grating laser in the prior art are mainly determined by the wavelength, reflectivity and bandwidth of the fiber grating 3 . However, the applicant h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com