High-performance air cathode catalyst layer suitable for metal air battery

A metal-air battery, air cathode technology, applied in battery electrodes, fuel cell-type half-cells and primary-cell-type half-cells, circuits, etc., can solve the problem of reducing the available active sites of active materials and not making full use of porous gels The high specific surface area of the framework and the stability of the catalytic layer are affected to achieve the effect of catalytic stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

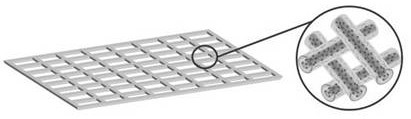

[0067] Step 1: The outer layer solution is selected from photosensitive polymer polyethylene glycol diacrylate (PEGDA), photoinitiator such as Irgacure 819 and carbon nanotubes are dispersed in phosphate buffered saline (PBS); the inner layer solution is selected from manganese dioxide nanodispersion liquid.

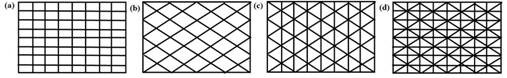

[0068] Step 2: Select a triangular pattern as the functional mesh pattern.

[0069] Step 3: Coaxially print a triangular mesh pattern on a nickel mesh substrate based on electrohydrodynamics. The high-voltage power supply is 18KV, the nozzle is 13cm away from the nickel mesh base, the outer nozzle is No. 16 nozzle, and the inner layer nozzle is No. 21 nozzle. During printing, maintain UV light conditions.

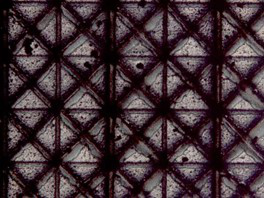

[0070] Step 4: Place the catalytic layer prepared in Step 3 in a freeze-drying oven and freeze-dry it at -60°C for 3 hours to obtain a triangular mesh pattern catalytic layer such as: image 3 shown.

[0071] The prepared rigid-flexible grid pattern catalytic laye...

specific Embodiment 2

[0073] Step 1: The outer layer solution is selected from the monomer hydroxyethyl methacrylate (HEMA), the crosslinking agent ethylene glycol dimethacrylate (EGDMA), the stabilizer polyvinylpyrrolidone (PVP), and the catalyst for catalyzing the polymerization reaction. Methylethylenediamine (TMEDA) and carbon nanotubes are dispersed in deionized aqueous solution; cobalt oxide nanodispersion is selected as the inner layer solution.

[0074] Step 2: Choose a square pattern as a functional grid pattern.

[0075] Step 3: Coaxially print a square grid pattern on a carbon cloth substrate based on electrohydrodynamics. The high-voltage power supply is 21KV, the nozzle is 15cm away from the nickel mesh base, the outer nozzle is No. 18 nozzle, and the inner layer nozzle is No. 24 nozzle. The printed catalytic layer was allowed to stand for 3 hours at room temperature to obtain a rigid and flexible catalytic layer with a square grid structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com