LKB direct vibration feeding system

A feeding system and direct vibration technology, applied in the direction of electrical components, electric switches, circuits, etc., can solve the problems of high failure rate of the balance bar, reduce the installation efficiency of the balance bar of the keyboard, etc., and achieve the effect of improving the installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Further detailed explanation through specific implementation mode below:

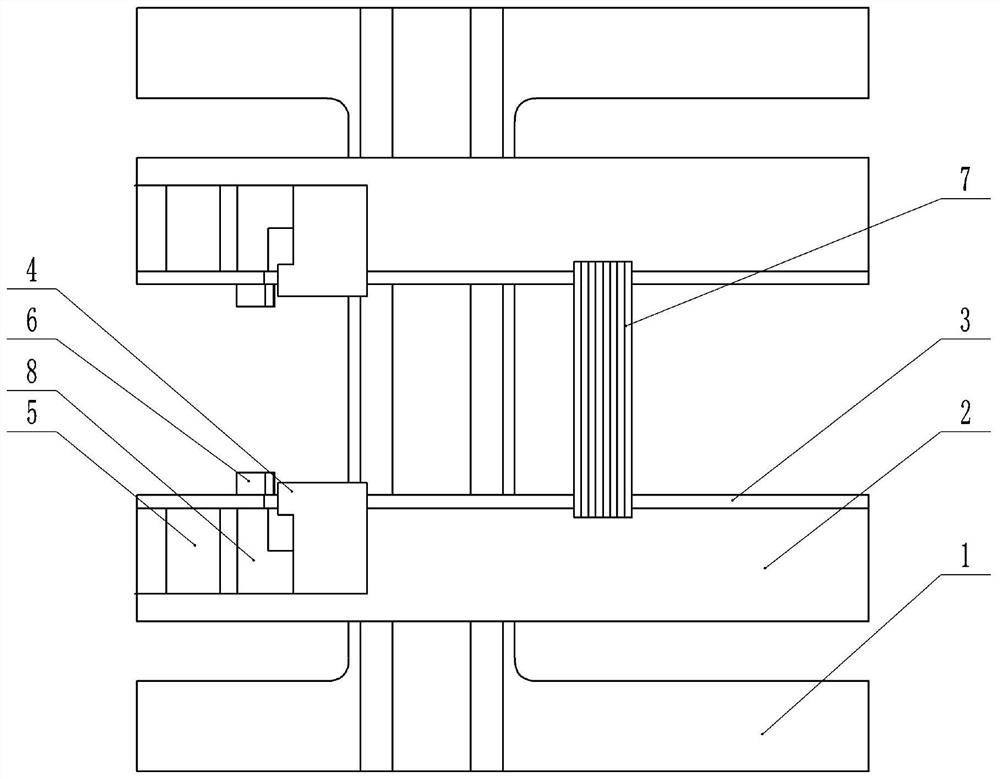

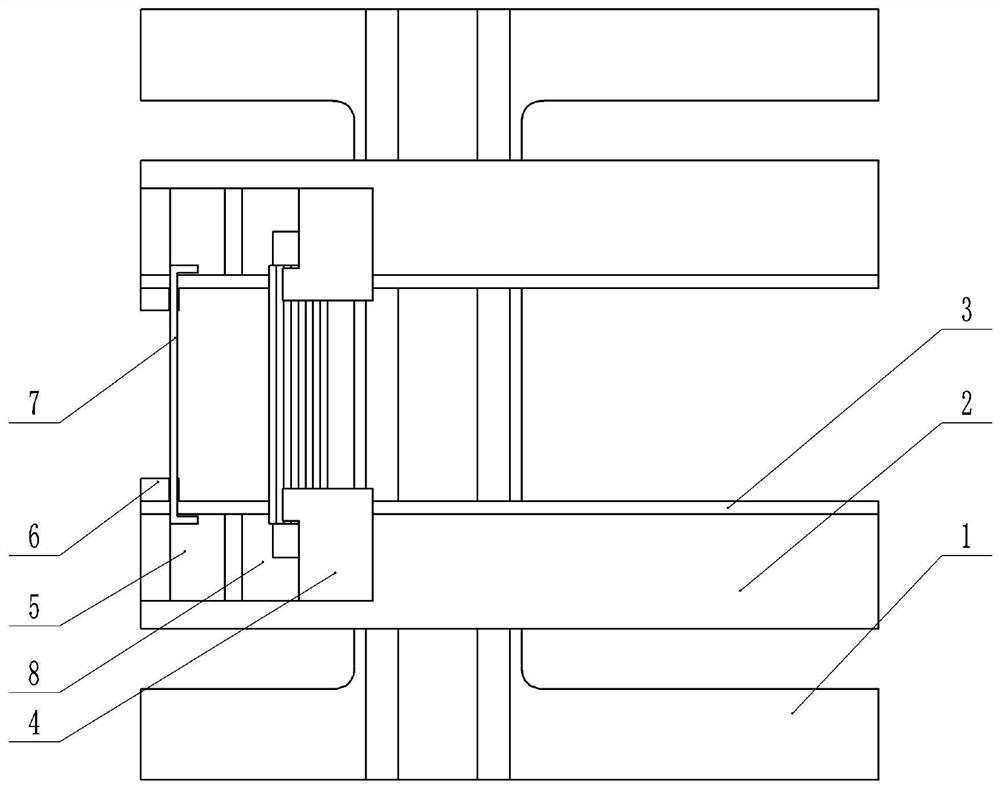

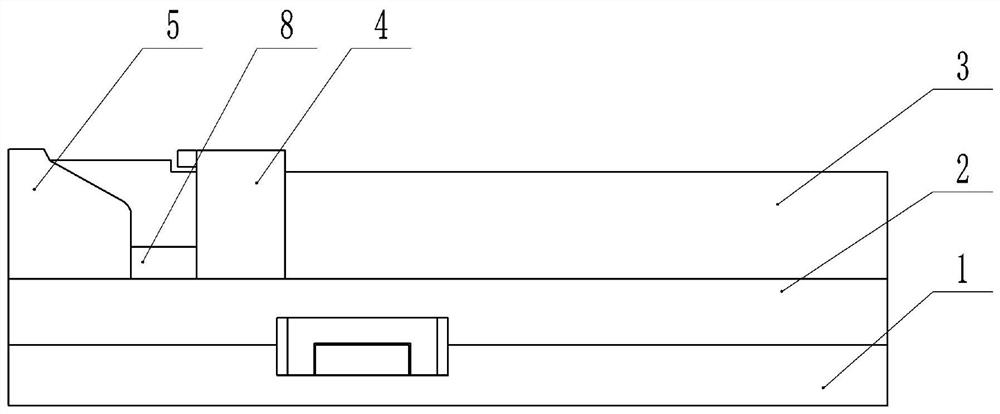

[0025] The reference signs in the accompanying drawings of the specification include: base 1 , bottom plate 2 , riser 3 , positioning seat 4 , inclined platform 5 , mounting seat 6 , balance bar 7 , and support block 8 .

[0026] The embodiment is basically as attached figure 1 , figure 2 and image 3 Shown: a LKB direct vibration feeding system, including a base 1 and two identically arranged feeding units, and the two feeding units are symmetrically arranged on the base 1. The base 1 is a base made of steel, which has a certain weight, so that it has good stability when using the feeding system of this solution.

[0027] The feeding unit includes a bottom plate 2 , a vertical plate 3 , moving parts and an inclined platform 5 . The bottom plate 2 is used to bear the weight of the structure arranged on it and provide an operation space. Riser 3 is used to hang the balance bar 7 to be instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com