Electron selective passivation contact structure, solar cell and preparation method

A technology of electron selectivity and solar cells, which is applied in the field of solar cells, can solve the problems of poor passivation contact performance, large near-infrared absorption loss, and poor passivation contact performance, so as to achieve low carrier recombination rate and improve photoelectricity. Transformation efficiency, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

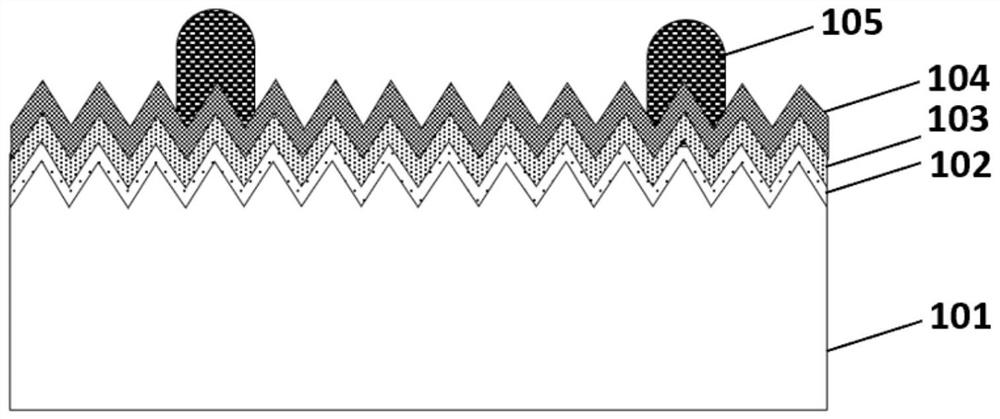

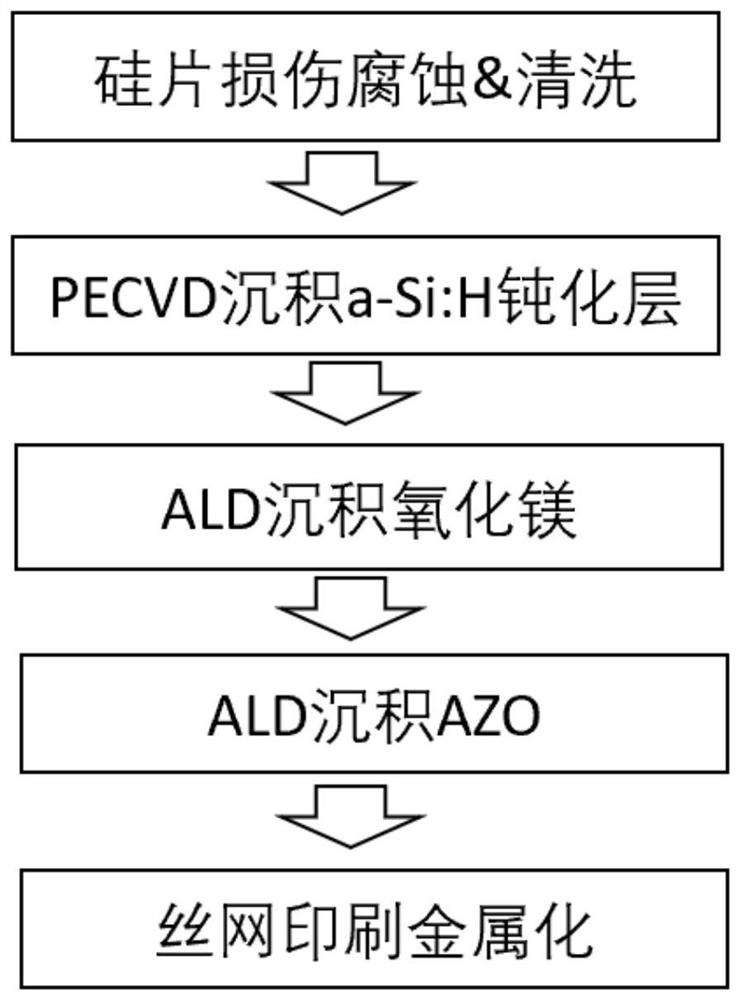

[0064] This embodiment provides a method for realizing electron selective passivation contact structure, and its structure and preparation process flow chart are respectively as follows figure 1 and figure 2 It mainly includes the following steps:

[0065] 1) select a kind of n-type single crystal silicon wafer, use potassium hydroxide KOH alkali solution to carry out polishing etching to remove the damaged layer and make texturing, then RCA cleaning to obtain silicon substrate 101;

[0066] 2) Using plasma enhanced chemical vapor deposition (PECVD) technology to deposit hydrogenated amorphous silicon (a-Si:H) tunneling passivation layer 102 on the surface of the silicon wafer, the thickness of the a-Si:H passivation layer is 5nm, and the deposition temperature is 200°C ;

[0067] 3) A magnesium oxide (MgO) film 103 is deposited on the a-Si:H passivation layer, prepared by atomic layer deposition (ALD), and the thickness is 3.0 nm;

Embodiment 2

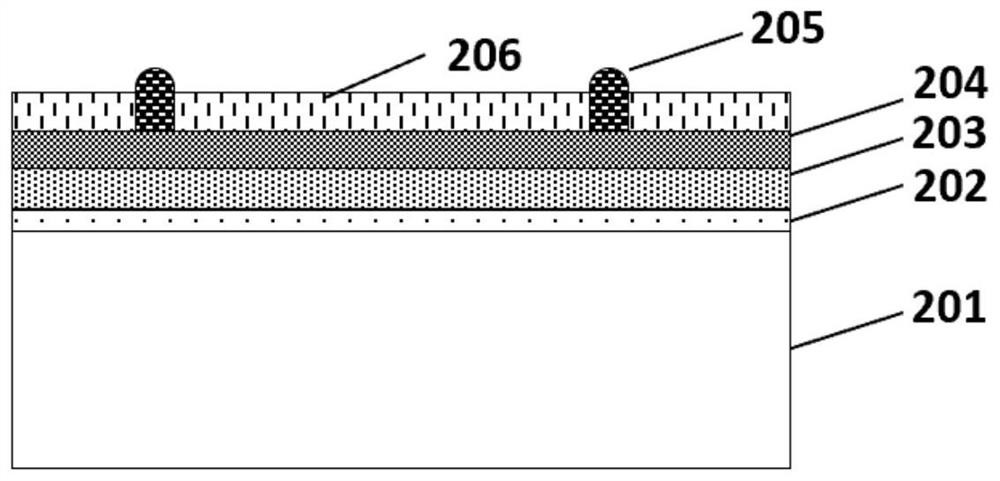

[0072] This embodiment provides a method for realizing an electron selective passivation contact structure based on Embodiment 1. The main feature is that an anti-reflection film is superimposed on the thinned ZnO transparent electrode to further reduce parasitic absorption and reflectivity. And the preparation process flow chart are as follows image 3 and Figure 4 As shown, it mainly includes the following process steps:

[0073] 1) select a kind of p-type single crystal silicon wafer, carry out polishing and etching with potassium hydroxide KOH alkali solution to remove the damaged layer, then RCA cleans to obtain silicon substrate 201;

[0074] 2) using PECVD to deposit a-Si:H tunneling passivation layer 202 on the surface of the silicon wafer, the thickness of the a-Si:H passivation layer is 5nm, and the deposition temperature is 200°C;

[0075] 3) ALD method is used to deposit MgO thin film 203 on the a-Si:H passivation layer with a thickness of 3.0 nm and a depositio...

Embodiment 3

[0081] This embodiment provides a method for realizing electron-selective passivation contact structure based on Embodiment 2, the main feature is that the tunneling silicon oxide (SiO 2 ) The passivation layer replaces the a-Si:H passivation layer and has higher transparency. Its structure and preparation process flow chart are as follows Figure 5 and Image 6 As shown, it mainly includes the following process steps:

[0082] 1) select a kind of n-type single crystal silicon wafer, use potassium hydroxide KOH alkali solution to carry out polishing and etching to remove the damaged layer, then RCA cleaning to obtain silicon substrate 301;

[0083] 2) Using ALD method to deposit tunnel SiO on the surface of silicon wafer 2 The passivation layer 302 has a thickness of about 1.5nm and a deposition temperature of 200°C;

[0084] 3) In SiO 2 ALD method is used to deposit MgO film 303 on the passivation layer, the thickness is 4.0nm, and the deposition temperature is 200℃;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com