Self-heating composition and application thereof

A composition and self-heating technology, which is applied to the types of packaging items, food heating containers, heat exchange materials, etc., can solve the problems of self-heating packaging that cannot be started normally, uneven pressure inside and outside the packaging volume, product transportation and inconvenient carrying, etc. , to achieve the effects of saving heating time, small proportion of packaging, and reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 A kind of self-heating composition

[0035] This embodiment is a self-heating composition A1, which includes the following components:

[0036] (1) Main heating reagent: 27g (1mol) of aluminum powder with a particle size of 5um, 304g (2mol) of chromium trioxide, 79g (0.5mol) of potassium permanganate and 58.5g (0.75mol) of calcium fluoride;

[0037] (2) Igniter: 9.1g (0.1mol) of zirconium powder with a particle size of 5um.

Embodiment 2~6

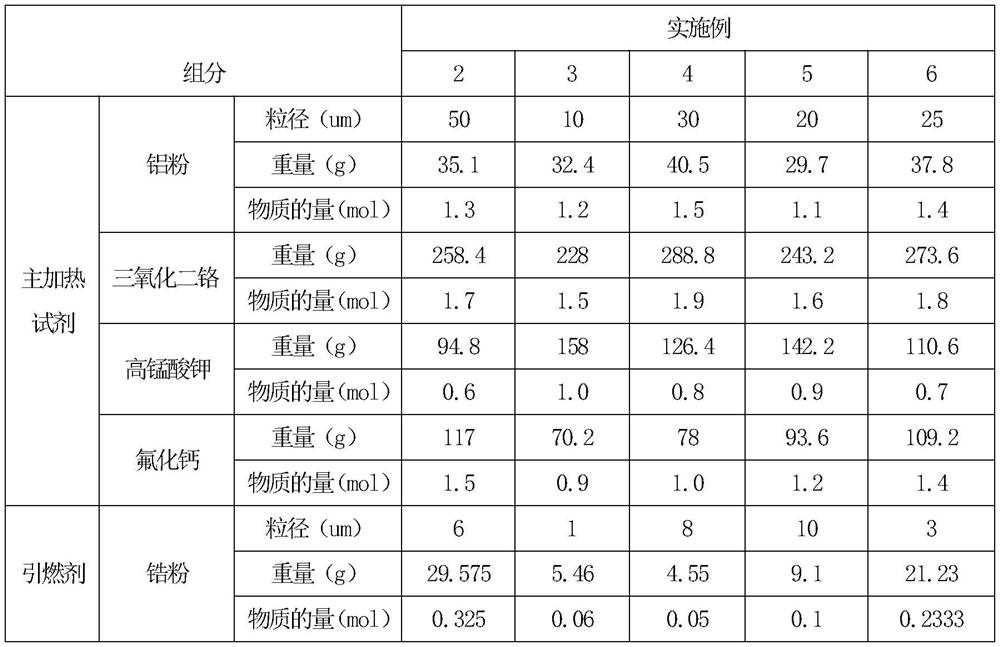

[0038] Examples 2-6 Self-heating compositions

[0039] Embodiments 2 to 6 are respectively a self-heating composition A2 to A6, and their components are shown in Table 1:

[0040] The dosage ratio of zirconium powder and aluminum powder is 0.1-0.5:2-3.

[0041] Table 1

[0042]

Embodiment 7 Embodiment 1~6

[0043] Example 7 Performance test of the self-heating compositions of Examples 1 to 6

[0044] This example is a performance test experiment for preparing the self-heating composition A1 in Example 1, and it includes the following contents:

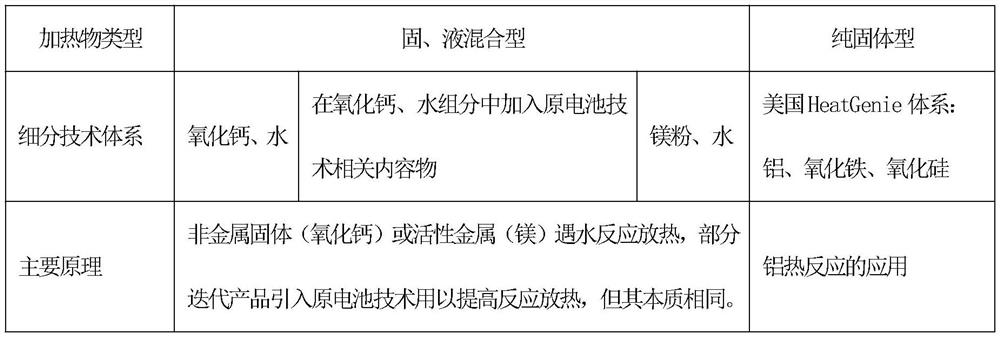

[0045] (1) Analyze the physicochemical properties of each component in the self-heating composition and the two sets of technical solutions announced by HeatGenie in the United States;

[0046] Among them, the self-heating composition B1 in the American HeatGenie I system: 17.9g of flake aluminum, 14.3g of potassium chlorate, 17.9g of solid silica, 3.5g of fumed silica, 10.7g of calcium fluoride, and 35.7g of sodium bentonite clay;

[0047] Self-heating composition B2 in the American HeatGenie II system: 17.3g of flake aluminum, 13.8g of potassium chlorate, 13g of solid silica, 3.5g of fumed silica, 10.4g of calcium fluoride, 34.3g of sodium bentonite clay, particle size of 3 Micron iron oxide 7.7g;

[0048] Take 7g of self-heating comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com