Preparation method of copper-silver composite material

A composite material, copper-silver technology, which is applied in the field of copper-silver composite material preparation, can solve the problems of monotonous color and high cost, and achieve the effects of changing patterns, low cost, strong artistic sense and admiration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

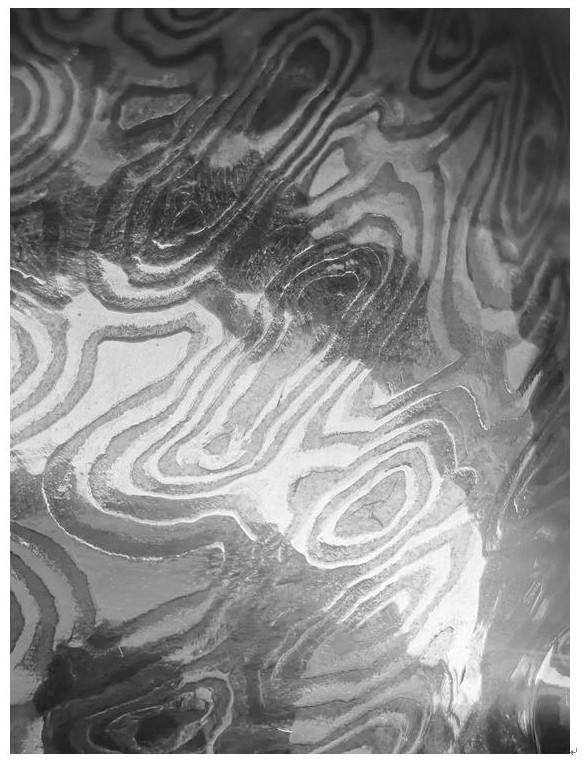

Image

Examples

Embodiment 1

[0022] A preparation method of a copper-silver composite material, specifically comprising the following steps:

[0023] (1) Grind the pure copper plate and silver plate to ensure that the surface of the pure copper plate and silver plate is smooth without pits, soak in dilute hydrochloric acid to remove the surface oxide layer, and then clean the pure copper plate and silver plate.

[0024] (2) Alternately stack pure copper plates and silver plates with a thickness of 10mm, put them directly into a graphite mold until the thickness of the rough blank is 130mm, and then put the mold into a spark plasma sintering furnace for sintering, under vacuum conditions At first, the temperature was raised to 230°C and then kept for 2 minutes, then the temperature was raised to 650°C and then kept for 25 minutes. During the sintering process, a pressure of 15Mpa was applied to the pure copper plate and the silver plate. After the sintering was completed, the furnace was cooled to room temp...

Embodiment 2

[0030] A preparation method of a copper-silver composite material, specifically comprising the following steps:

[0031] (1) Grind the pure copper plate and silver plate to ensure that the surface of the pure copper plate and silver plate is smooth without pits, soak in dilute hydrochloric acid to remove the surface oxide layer, and then clean the pure copper plate and silver plate.

[0032] (2) Alternately stack pure copper plates and silver plates with a thickness of 15mm, put them directly into a graphite mold, until the thickness of the rough blank is 150mm, and then put the mold into a discharge plasma sintering furnace for sintering, and fill it with purity 99.999% argon with a flow rate of 80ml / min was used for protective sintering. First, the temperature was raised to 250°C and then kept for 1min. Then, the temperature was raised to a sintering temperature of 680°C and then kept for 20min. During the sintering process, a pressure of 10Mpa was applied to the pure copper ...

Embodiment 3

[0038] A preparation method of a copper-silver composite material, specifically comprising the following steps:

[0039] (1) Grind the pure copper plate and silver plate to ensure that the surface of the pure copper plate and silver plate is smooth without pits, soak in dilute hydrochloric acid to remove the surface oxide layer, and then clean the pure copper plate and silver plate.

[0040] (2) Alternately stack pure copper plates and silver plates with a thickness of 14mm, put them directly into a graphite mold until the thickness of the rough blank is 140mm, and then put the mold into a spark plasma sintering furnace for sintering, under vacuum conditions At first, the temperature was raised to 200°C and then kept for 2min, then the temperature was raised to 660°C and then kept for 22min. During the sintering process, a pressure of 30Mpa was applied to the pure copper plate and the silver plate. After the sintering was completed, it was cooled to room temperature with the fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com