Preparation method of polyether amine catalyst and polyether amine

A polyether amine and catalyst technology, applied in the field of organic polymer compounds, can solve the problems of high catalyst cost, high price, and environmental pollution, and achieve the effects of sufficient and uniform metal adsorption, process and cost saving, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

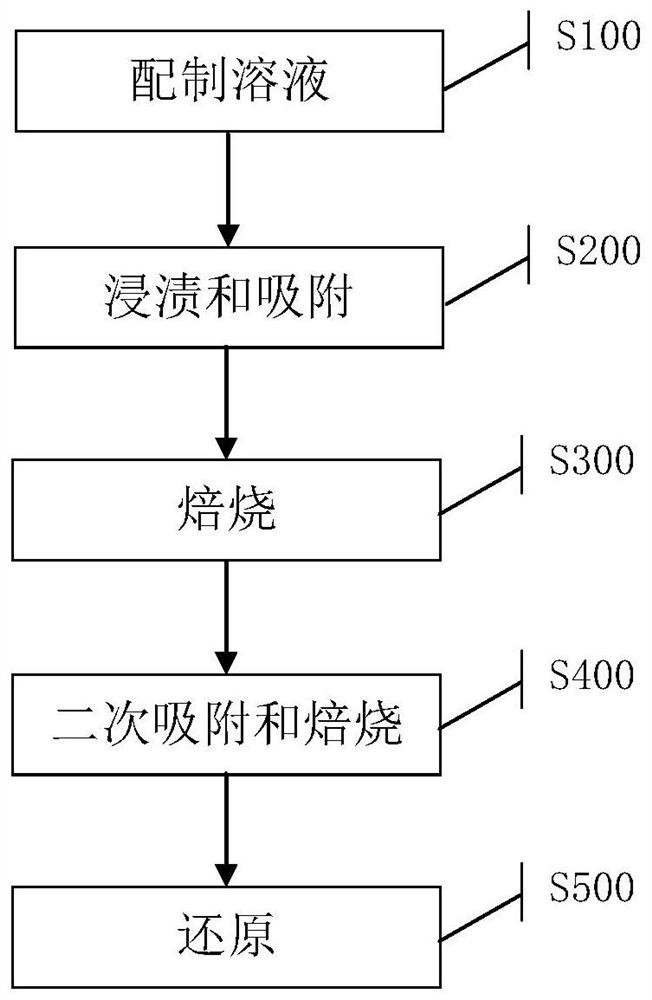

[0033] see figure 1 , the invention provides a preparation method of a polyetheramine catalyst, the polyetheramine catalyst is a supported metal catalyst, using γ-Al 2 O 3 As the carrier, basic copper carbonate, basic nickel carbonate and basic cobalt carbonate are used as the precursors of the supported metals, and the polyetheramine catalyst is prepared after twice adsorption roasting and one reduction by the equal volume impregnation method; the specific steps include:

[0034] Step S100. Prepare a solution: add basic copper carbonate, basic nickel carbonate and basic cobalt carbonate to deionized water, stir until basic copper carbonate, basic nickel carbonate and basic cobalt carbonate are completely dissolved to obtain solution A; The stirring temperature is preferably 60° C., and the stirring time is preferably 30 min.

[0035] Step S200. Impregnation and adsorption: the alumina carrier is immersed in the solution A obtained in S1, and after being immersed in a water ...

Embodiment 1

[0046] 1. Preparation of polyetheramine catalyst: first add 450g basic nickel carbonate, 50g basic copper carbonate and 30g basic cobalt carbonate into deionized water, heat to 40°C and stir to fully dissolve to form a solution; then Weighed 700g γ-Al by the equal volume dipping method 2 O 3 The carrier was immersed in the above mixed solution, immersed in a water bath at 40 °C for 30 min, and after the adsorption equilibrium was reached, the temperature was raised to 90 °C for vacuum dehydration and drying, and then calcined at 400 °C for 4 hours; The metal salt solution was prepared in the same proportion, and the second impregnation, adsorption and calcination were carried out; after the final cooling, the carrier after the secondary calcination was rotated and reduced for 60 hours under a hydrogen atmosphere at 420 °C in a reduction furnace to obtain the self-made polyetheramine. Catalyst (supported metal catalyst).

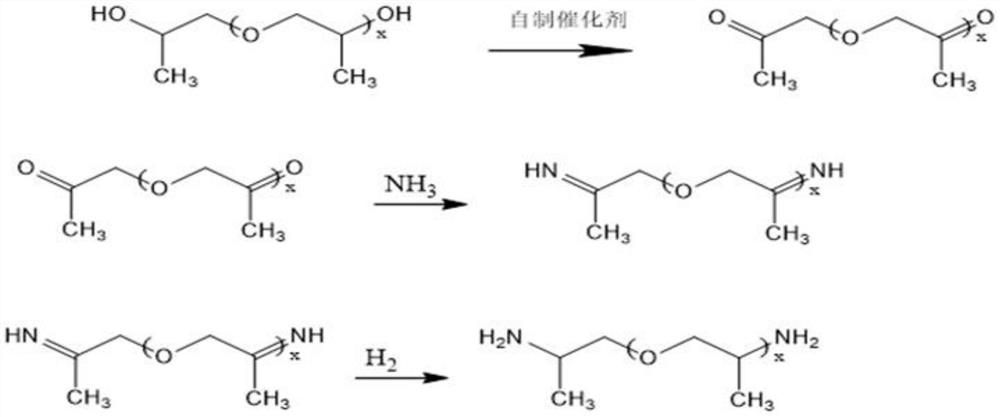

[0047] 2. The synthetic chemical equation of polyethe...

Embodiment 2

[0051] 1. Preparation of polyetheramine catalyst: first add 400g basic nickel carbonate, 80g basic copper carbonate and 50g basic cobalt carbonate into deionized water, heat to 40°C and stir to fully dissolve to form a solution; then Weighed 800g γ-Al by the equal volume dipping method 2 O 3 The carrier was immersed in the above mixed solution, immersed in a water bath at 40 °C for 30 min, and after the adsorption equilibrium was reached, the temperature was raised to 90 °C for vacuum dehydration and drying, and then calcined at 420 °C for 6 h; The metal salt solution was prepared in the same proportion, and the second impregnation, adsorption and calcination were carried out; after the final cooling and cooling, the carrier after the secondary calcination was rotated and reduced in a reducing furnace at 420 °C for 70 hours to obtain the self-made polyetheramine. Catalyst (supported metal catalyst).

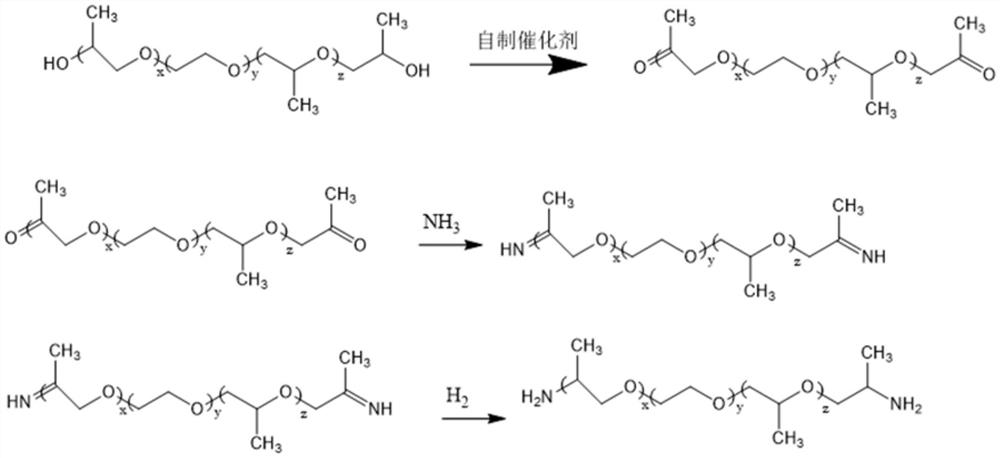

[0052] 2. The synthetic chemical equation of polyetheramine is as follows:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com