Porous carbon composite material with core-shell structure as well as preparation method and application thereof

A composite material, core-shell structure technology, applied in the field of tobacco waste recycling, can solve the problems of large randomness, no literature report, rare porous carbon materials, etc., to improve the contribution, avoid the loss of nicotine, improve the The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

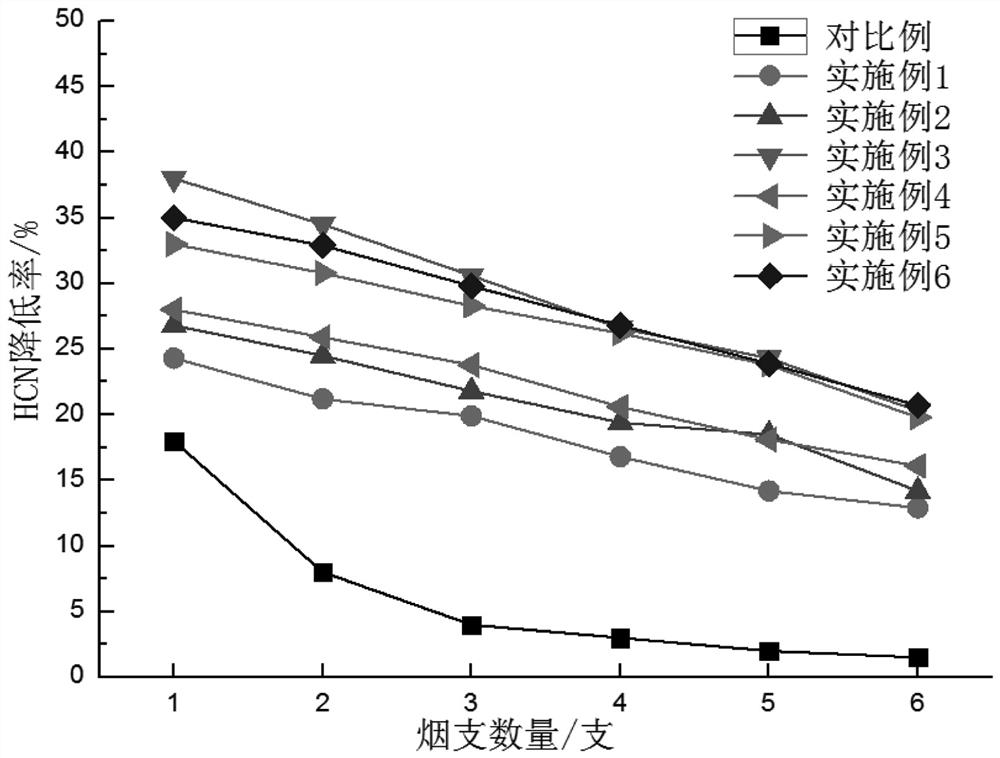

Embodiment 1

[0039] This embodiment provides a porous carbon composite material with a core-shell structure, which is granular and consists of porous carbon particles and a silicon dioxide porous layer that wraps the porous carbon particles. Wherein, the porous carbon particles are hierarchical nitrogen-containing porous carbon particles with a particle size of 20-40 mesh. The silicon dioxide porous layer has a thickness of 150-200 nm, and the silicon dioxide porous layer includes several micropores, and the diameter of the micropores is 1.2 nm.

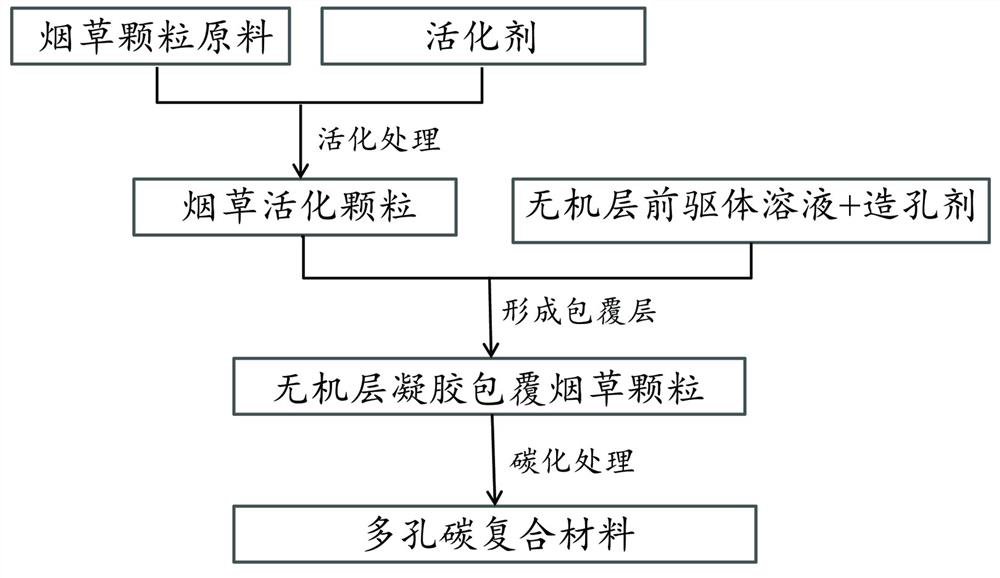

[0040] see figure 1 , this embodiment also provides a method for preparing the above-mentioned porous carbon composite material with a core-shell structure, including:

[0041] Raw material pretreatment Wash the tobacco leaves and place them in an oven at 50°C to dry until the moisture content is below 10%, then crush them to 20-40 mesh to obtain raw tobacco particles;

[0042] Activation treatment Weigh 10 g of the obtained tobacco granule raw...

Embodiment 2

[0047] This embodiment provides a porous carbon composite material with a core-shell structure, which is in granular form and consists of porous carbon particles and a porous silica layer wrapping several of the porous carbon particles. Wherein, the porous carbon particles are hierarchical nitrogen-containing porous carbon particles with a particle size of 100-200 mesh. The silicon dioxide porous layer has a thickness of 100-150 nm, the silicon dioxide porous layer includes several micropores, and the diameter of the micropores is 1.7 nm.

[0048] This example also provides a method for preparing the above-mentioned porous carbon composite material with a core-shell structure, which is basically the same as the method provided in Example 1, the main difference being that "forming a coating layer" is different, specifically , SiCl 4 The concentration of the ether solution was 3%, the molar ratio of ethylenediamine to the silica porous layer was 1:1, and the step of "forming a ...

Embodiment 3

[0050] This embodiment provides a porous carbon composite material with a core-shell structure, which is in granular form and consists of porous carbon particles and a porous silica layer wrapping several of the porous carbon particles. Wherein, the porous particles are hierarchical nitrogen-containing porous carbon particles with a particle size of 40-80 mesh. The silicon dioxide porous layer has a thickness of 50-100 nm, and the silicon dioxide porous layer includes several micropores, and the diameter of the micropores is 0.9 nm.

[0051] This example also provides a method for preparing the above-mentioned porous carbon composite material with a core-shell structure, which is basically the same as the method provided in Example 1, the main difference being that "forming a coating layer" is different, specifically , SiCl 4 The concentration of the ether solution was 1%, the molar ratio of ethylenediamine to the silicon dioxide porous layer was 6: 1, and the "coating layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com