Bifidobacterium longum CCFM1206 capable of producing sulforaphane and relieving inflammation

A CCFM1206, Bifidobacterium longum technology, applied in the field of microorganisms, to achieve the effect of improving colonic barrier function, increasing the content and reducing the level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

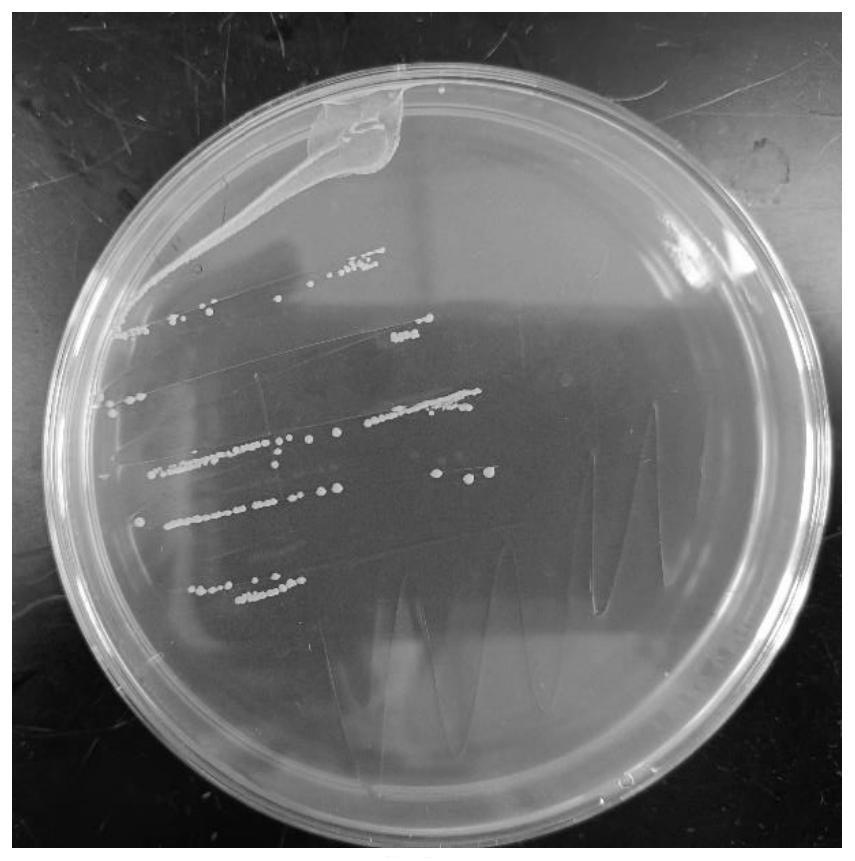

[0072] Example 1: Screening, identification, observation and preservation of Bifidobacterium longum CCFM1206.

[0073] 1. Filter

[0074] Take 0.5 g of fresh fecal samples from healthy adults and add them to 4.5 mL of 0.9% normal saline for gradient dilution. Select the appropriate gradient dilution and spread it in MRS solid modified medium supplemented with 0.2% bromocresol purple. Incubate under anaerobic conditions at 37°C for 24-48h. A single colony whose discoloration circle obviously turned yellow was inoculated onto an MRS plate for streaking and purification, and a single colony was picked and transferred to a liquid MRS liquid medium for enrichment, and stored in 30% glycerol to obtain the strain Bifidobacterium longum CCFM1206.

[0075] 2. Identification

[0076] The whole genome DNA of strain CCFM1206 was extracted for the amplification of 16S rDNA, and the amplified DNA fragments were collected and sequenced (completed by Suzhou Jinweizhi Biotechnology Co., Ltd....

Embodiment 2

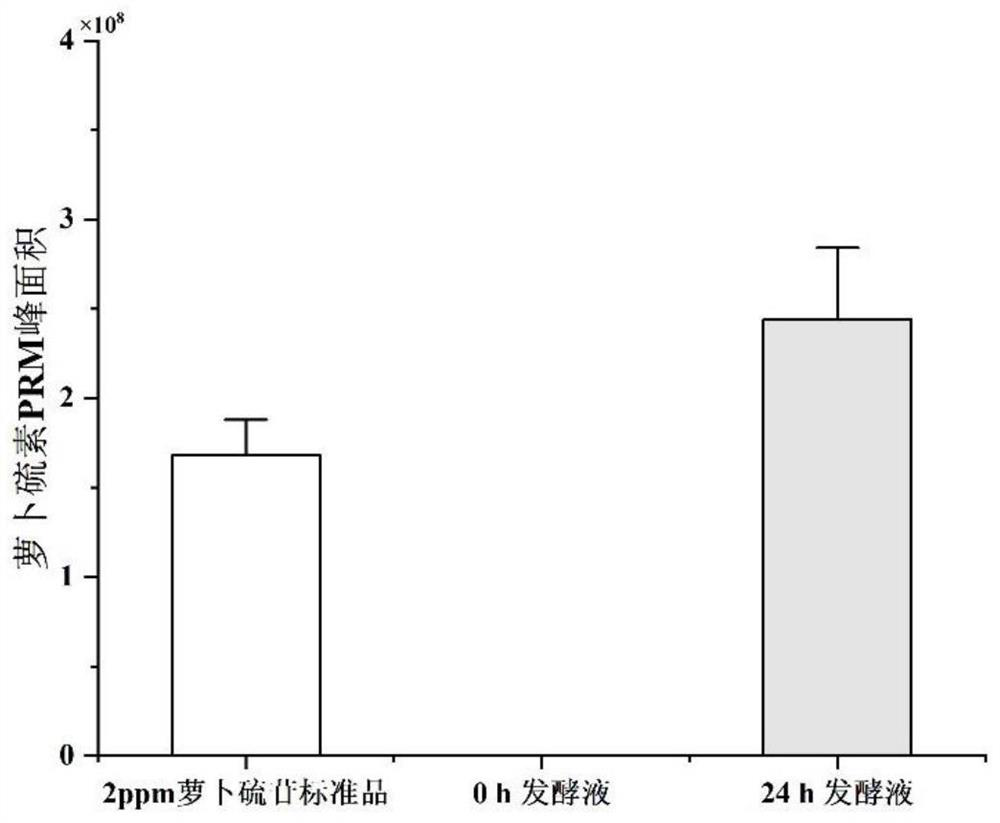

[0081] Example 2: Fermentation of Bifidobacterium longum CCFM1206 to produce sulforaphane

[0082] Bifidobacterium longum CCFM1206 stored at -80°C was streaked in MRS solid medium, cultured anaerobic at 37°C for 24 to 48 hours, and then passaged in MRS liquid medium for 2 to 3 times. The inoculum was inoculated into the modified MRS liquid medium, and cultured anaerobic at 37 °C for 24 h, and the obtained fermentation broth was used for the detection of sulforaphane content.

[0083] The result is as figure 2shown. The inoculated medium did not contain sulforaphane, and the content of sulforaphane was 16.76 μM detected after 24 hours of fermentation by Bifidobacterium longum CCFM1206.

Embodiment 3

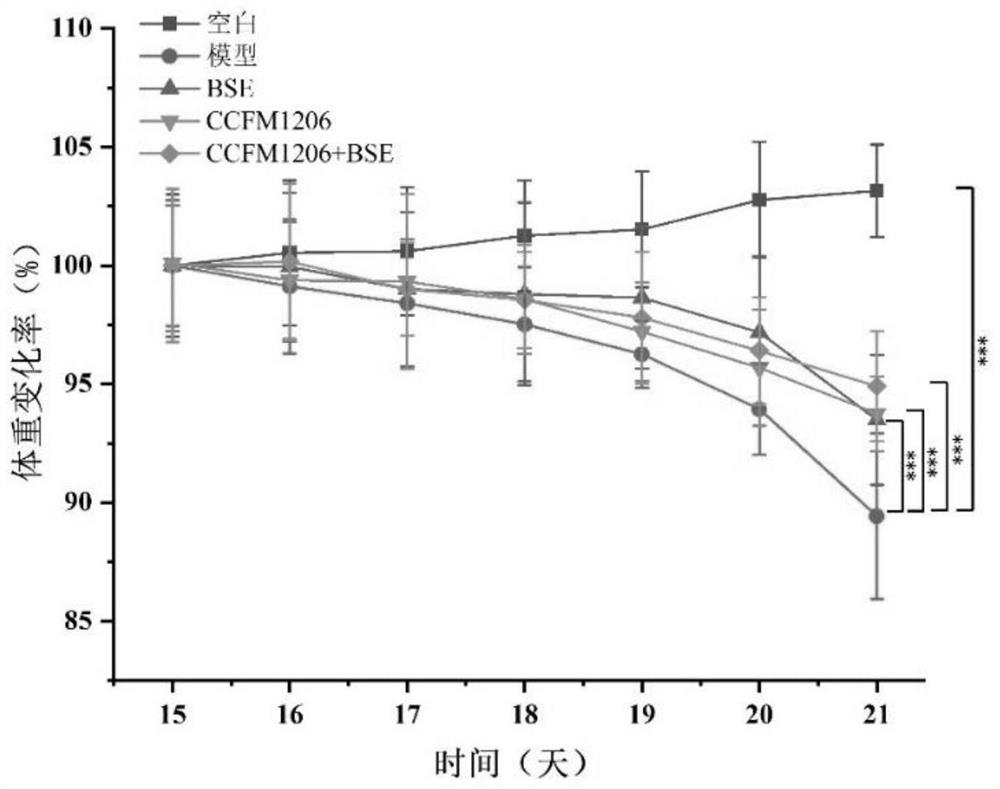

[0084] Example 3: Effects of Bifidobacterium longum CCFM1206 and glucoraphanin-containing diet on disease symptoms in UC mice:

[0085] Forty 6-week-old healthy male C57BL / 6J mice were randomly divided into 5 groups with 8 mice in each group after one week of acclimatization. The 5 groups were blank group, model group, glucoraphanin-containing diet group (BSE), Bifidobacterium longum CCFM1206 group (CCFM1206), and glucoraphanin-containing diet compound Bifidobacterium longum CCFM1206 group (BSE+CCFM1206).

[0086] Days 8-21 were the 14-day gavage intervention period. The dose of each gavage was 0.2 mL per animal, and the gavage time was the same every day. Among them, the control group and model group were intragastrically administered with normal saline, the BSE group was intragastrically administered with 40 mg / mL broccoli seed aqueous extract solution, and the CCFM1206 group was intragastrically administered with 5 × 10 9 CFU / mL bacterial suspension, BSE+CCFM1206 group con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viable count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com