High-strength mulching film easy to recycle and preparation method thereof

A technology that is easy to recycle and mulch, applied in botany equipment and methods, horticulture, plant protection covers, etc., can solve problems such as soil pollution, soil hazards, poisoning, etc., to improve mechanical properties, reduce secondary pollution, and realize The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

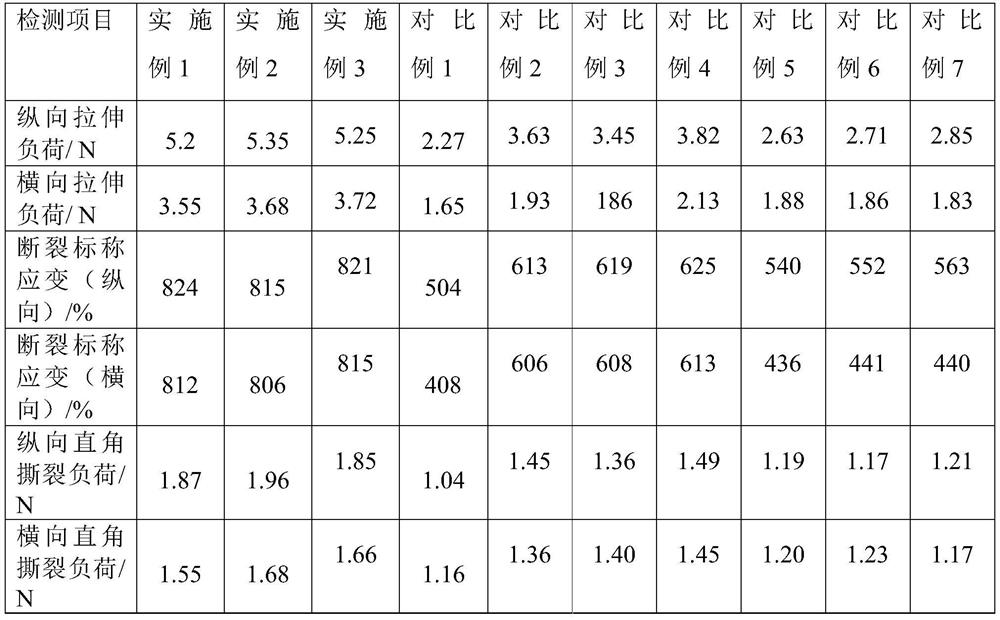

Examples

Embodiment 1

[0047] The production width is 1.2 meters and the thickness is 0.012um. The high-strength and easy-to-recycle mulch film is made of the following components by weight: linear low-density polyethylene 55%, metallocene polyethylene 25%, anti-aging masterbatch for mulch film 10%, Reinforcing and toughening masterbatch 10%;

[0048] The anti-aging masterbatch for mulching film is made of the following components by weight: 92% of low density high pressure polyethylene, 2% of light stabilizer, 1% of antioxidant, 1% of ultraviolet absorber, 2% of dispersant, Lubricant 2%.

[0049] The said strengthening and toughening masterbatch is made of the following components by weight: 20% of PBAT, 15% of toughening compatibilizer, 60% of modified calcium sulfate whiskers, 2% of dispersant, 1% of lubricant, Oxygen 2%.

[0050] The preparation process of the modified calcium sulfate crystal whisker is as follows: after the titanate coupling agent (NDZ-201) is diluted with an acetone solution...

Embodiment 2

[0056] The production width is 1.2 meters and the thickness is 0.012um. The high-strength and easy-to-recycle mulch film is made of the following components by weight: linear low-density polyethylene 60%, metallocene polyethylene 20%, anti-aging masterbatch for mulch film 8%, Reinforcing and toughening masterbatch: 12%;

[0057] The anti-aging masterbatch for mulching film is made of the following components by weight: 90% of low density high pressure polyethylene, 4% of light stabilizer, 2% of antioxidant, 1.5% of ultraviolet absorber, 1.5% of dispersant, Lubricant 1%.

[0058] The reinforcing and toughening masterbatch is made of the following components by weight: 22% of PBAT, 13% of toughening compatibilizer, 60% of modified calcium sulfate whiskers, 1% of dispersant, 2% of lubricant, Oxygen 2%.

[0059] The preparation method of the described high-strength and easy-to-recover mulch film is the same as that in Example 1.

Embodiment 3

[0061] The high-strength and easy-to-recycle mulch film with a width of 1.2 meters and a thickness of 0.012um is produced. It is made of the following components by weight: 50% of linear low-density polyethylene, 28% of metallocene polyethylene, 9% of anti-aging masterbatch for mulch film, Reinforcing and toughening masterbatch: 13%;

[0062] The anti-aging masterbatch for mulching film is made of the following components by weight percentage: 88% of low-density high pressure polyethylene, 4% of light stabilizer, 4% of antioxidant, 1% of ultraviolet absorber, 1% of dispersant, Lubricant 2%.

[0063] The reinforcing and toughening masterbatch is made of the following components by weight percentage: PBAT 18%, toughening compatibilizer 17%, modified calcium sulfate whisker 57%, dispersant 3%, lubricant 2%, anti- Oxygen 3%.

[0064] The preparation method of the described high-strength and easy-to-recover mulch film is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap