Rare earth ion doped chalcogenide gain glass and low-temperature synthesis preparation method thereof

A technology of rare earth ions and sulfur doping, which is applied in the field of infrared laser materials and its preparation, can solve the problems of high melting temperature, achieve the effects of reducing melting temperature, reducing safety risks, and reducing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

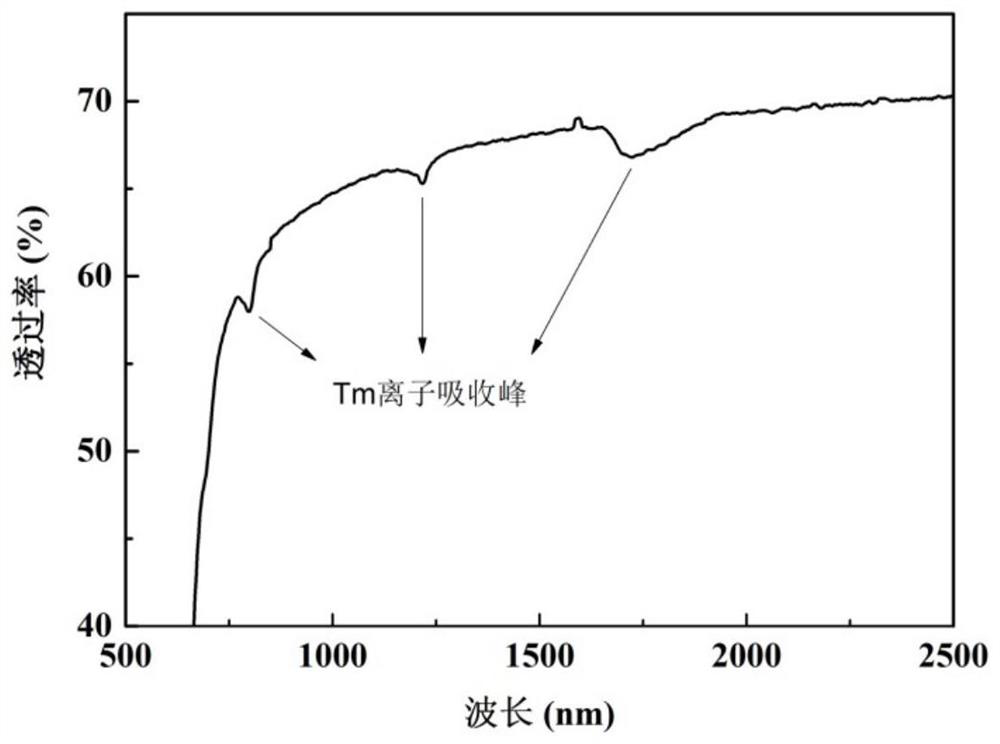

[0027] Example 1: A rare earth ion doped chalcogenide gain glass, the molar content of the raw material components is Ga: 0.8%, As: 38.2%, Sb: 1%, S: 60%, the rare earth element is Tm, doped The concentration is 1000 ppm. The process of preparing rare earth ion-doped chalcogenide gain glass according to the above-mentioned raw material components is as follows:

[0028] (1) Weigh Ga, As, Sb and Tm elemental raw materials with a purity of not less than 99.99% according to the formula, load the weighed raw materials into a quartz tube, and then evacuate the quartz tube, and the vacuum degree reaches 1 × 10 -3 After Pa, seal the quartz tube with oxyhydrogen flame;

[0029] (2) put the sealed quartz tube into a melting furnace, heat up to 700 ° C and melt for 8 hours, take out the quartz tube and cool to obtain an alloy containing rare earth elements;

[0030] (3) Load the alloy and the weighed sulfur with a purity of not less than 99.99% into a quartz tube, and then evacuate th...

Embodiment 2

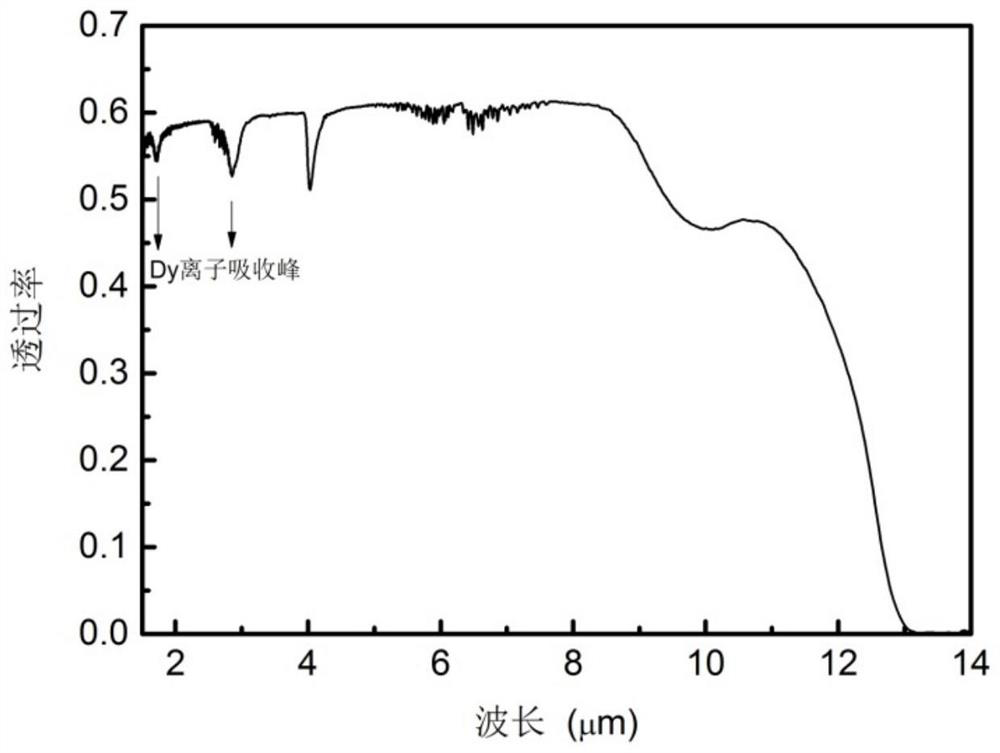

[0033] Example 2: A rare earth ion doped chalcogenide gain glass, the molar content of the raw material components is Ga: 0.8%, As: 34.2%, Sb: 5%, S: 60%, the rare earth element is Dy, and the doped The concentration is 4000ppm. The process of preparing rare earth ion-doped chalcogenide gain glass according to the above components is as follows:

[0034] (1) Weigh Ga, As, Sb and Dy elemental raw materials with a purity of not less than 99.99% according to the formula, load the weighed raw materials into a quartz tube, and then evacuate the quartz tube, and the vacuum degree reaches 1 × 10 -3 After Pa, seal the quartz tube with oxyhydrogen flame;

[0035] (2) put the sealed quartz tube into a melting furnace, heat up to 700 ° C for melting for 8 hours, take out the quartz tube for cooling, and obtain an alloy containing rare earth elements;

[0036] (3) Put the alloy and sulfur that has been weighed and whose purity is not less than 99.99% into a quartz tube, and then vacuumi...

Embodiment 3

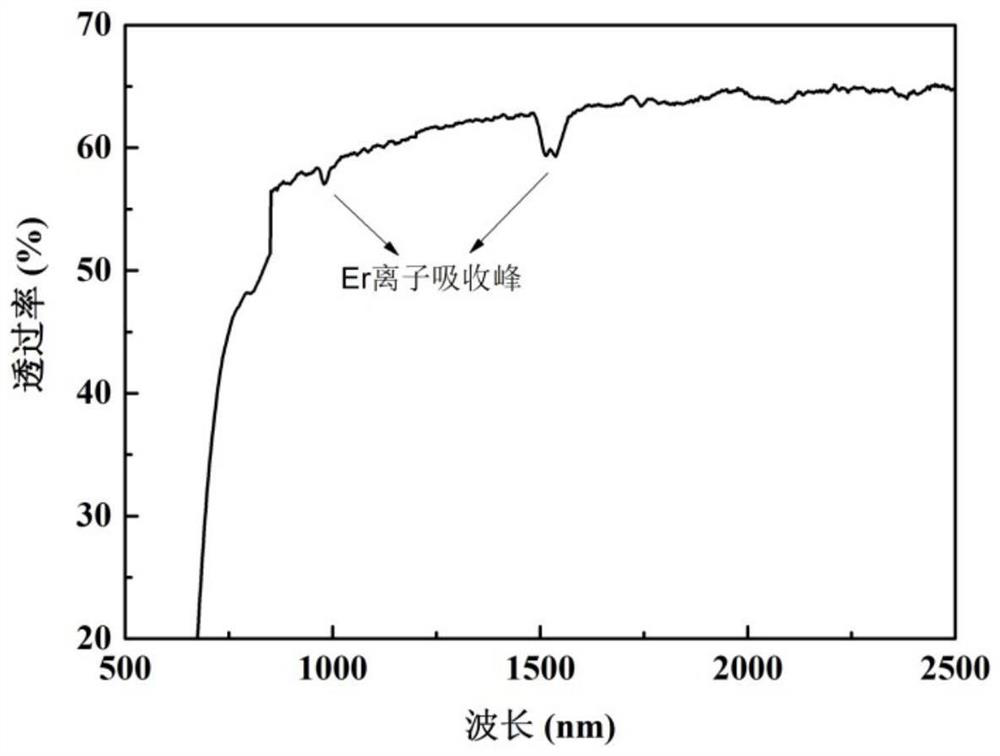

[0039] Example 3: A rare earth ion doped chalcogenide gain glass, the molar content of the raw material components is Ga: 0.8%, As: 30.2%, Sb: 9%, S: 60%, the rare earth element is Er, doped The concentration is 2000ppm. The process of preparing rare earth ion-doped chalcogenide gain glass according to the above components is as follows:

[0040] (1) Weigh Ga, As, Sb and Er elemental raw materials with a purity of not less than 99.99% according to the formula, load the weighed raw materials into a quartz tube, and evacuate the quartz tube until the degree of vacuum reaches 1×10 -3 After Pa, seal the quartz tube with oxyhydrogen flame;

[0041] (2) put the sealed quartz tube into a melting furnace, heat up to 700 ° C for melting for 8 hours, take out the quartz tube for cooling, and obtain an alloy containing rare earth elements;

[0042] (3) Load the alloy and the weighed sulfur with a purity of not less than 99.99% into a quartz tube, and then evacuate the quartz tube to a de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com