Hydrogen power metal solid deposition device and method

A deposition device and power technology, applied in the field of hydrogen powered metal solid-state deposition devices, can solve the problems of high price, limited effect, accelerated gas temperature, etc., and achieve the effects of improving interface bonding, low cost, and reducing oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

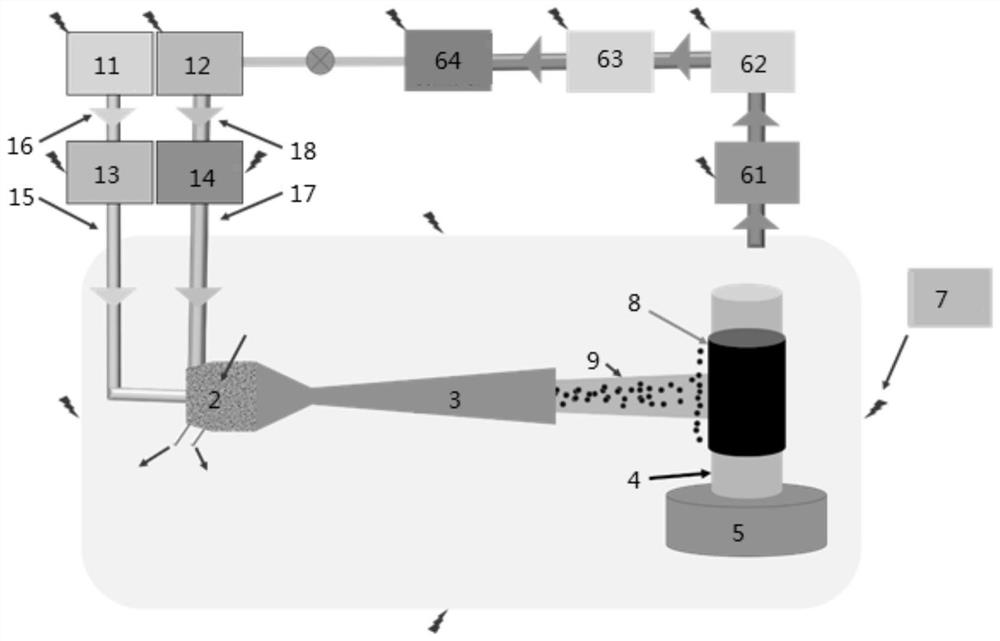

[0072] This embodiment provides a hydrogen powered metal solid state deposition device, including a powder feeding hydrogen source 11, an accelerating hydrogen source 12, a powder feeding device 13, a gas heater 14, a first powder feeding tube 15, a second powder feeding tube 16, The first main gas pipe 17, the second main gas pipe 18, the powder preheating reaction chamber 2, the thermocouple, the pressure detector, the Rafal nozzle 3, the base body 4, the rotary table 5, the air pump 61, the filter 62, the compressor 63 , hydrogen storage tank 64, hydrogen detector 7, master control system and multiple pipes.

[0073] The outlet of the powder feeding hydrogen source 11 is connected to the inlet of the powder feeder 13 through the second powder feeding pipe 16 , and the outlet of the powder feeder 13 is connected to the inlet of the powder preheating reaction chamber 2 through the first powder feeding pipe 15 . The outlet of the accelerated hydrogen source 12 is connected to ...

Embodiment 2

[0080] This embodiment provides a hydrogen-powered metal solid-state deposition method, which is performed using the hydrogen-powered metal solid-state deposition device in Embodiment 1.

[0081] Specifically: when spraying, the powder-feeding hydrogen from the powder-feeding hydrogen source 11 enters the high-pressure powder feeder 13 through the second powder-feeding pipe 16, and carries the micron-sized powder particles to be sprayed in the powder feeder 13 through the first powder-feeding device. The tube 15 enters the powder preheating reaction chamber 2; the high-pressure hydrogen drawn from the accelerated hydrogen source 12 enters the gas heater 14 (tubular gas heater 14) through the second main gas pipe 18, and after heating, passes through the first main gas pipe 17 to the gas heater 14. In the powder preheating reaction chamber 2; at this time, the powdered hydrogen, accelerated hydrogen and powder particles in the powder preheated reaction chamber 2 are fully mixed,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com