Preparation of three-dimensional prismatic manganese oxide molecular sieve catalytic material and application of three-dimensional prismatic manganese oxide molecular sieve catalytic material in degradation of organic pollutants

A technology for organic pollutants and catalytic materials, which is applied in the field of preparation of three-dimensional prismatic manganese oxide molecular sieve catalytic materials, can solve the problems of restricting diffusion and mass transfer of organic molecules, unfavorable reaction kinetics, restricting catalytic activity, etc., and achieves high yield , large specific surface area, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

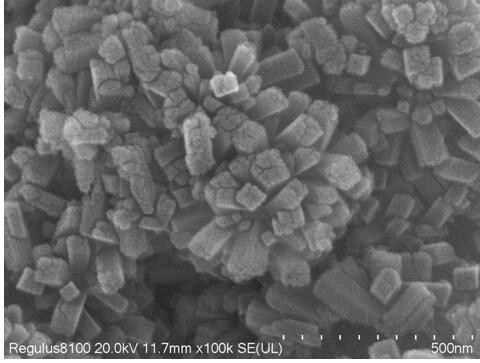

[0025] (1) Preparation of manganese oxide molecular sieve catalytic material: At room temperature, 26 mmol of manganese sulfate, 0.088 mmol of phosphomolybdic acid and 1.5 mL of nitric acid (concentration 0.15 g / mL) were dissolved in 15 mL of distilled water. 50 mL of distilled aqueous solution was added dropwise to the above mixed solution, and after stirring and mixing evenly, the reaction was stirred at 100 ° C for 24 hours, filtered, washed with distilled water, and dried at 50 ° C for 10 hours to obtain a manganese oxide molecular sieve catalytic material. The SEM, SEM and XRD spectra of the manganese oxide molecular sieve catalytic material are as follows figure 1 , 2 shown;

[0026] (2) Application of degrading organic pollutants in water: adding manganese oxide molecular sieve catalytic material (the concentration of catalytic material in wastewater is 200 mg / L) to 20 mg / L acid scarlet G dye wastewater; stirring reaction at room temperature under air atmosphere After...

Embodiment 2

[0030] (1) Preparation of manganese oxide molecular sieve catalytic material: At room temperature, dissolve 52 mmol manganese acetate, 0.35 mmol ammonium phosphomolybdate and 3 mL nitric acid (concentration 0.15 g / mL) in 30 mL distilled water, and dissolve 100 mL containing 37 mmol potassium permanganate into 30 mL distilled water. The distilled aqueous solution was added dropwise to the above mixed solution, and after stirring and mixing evenly, the reaction was stirred at 50° C. for 24 hours, filtered, washed with distilled water, and dried at 150° C. for 24 hours to obtain a manganese oxide molecular sieve catalytic material. The structure of the manganese oxide molecular sieve catalytic material is similar to that of Example 1;

[0031] (2) Application of degrading organic pollutants in water: Add manganese oxide molecular sieve catalytic material (the concentration of this catalytic material in the wastewater is 50 mg / L) into 200 mg / L acid orange 7 dye wastewater, and unde...

Embodiment 3

[0035] (1) Preparation of manganese oxide molecular sieve catalytic material: At room temperature, dissolve 0.037mol manganese sulfate, 0.0185mol phosphomolybdic acid and 30mL nitric acid (concentration 0.15g / mL) in 300mL distilled water, and dissolve 0.37mol potassium permanganate 1L of distilled water solution was added dropwise to the above mixed solution, after stirring and mixing evenly, the reaction was stirred at 80°C for 20 hours, filtered, washed with distilled water, and dried at 50°C for 15 hours to obtain a manganese oxide molecular sieve catalytic material. The structure of the manganese oxide molecular sieve catalytic material is similar to that of Example 1;

[0036] (2) Application of degrading organic pollutants in water: add potassium peroxymonosulfate (the concentration of potassium hydrogen persulfate is 500mg / L) to 50mg / L of mezatrione dye wastewater, and then add manganese oxide molecular sieve to the wastewater to catalyze material (the concentration of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com