Efficient denitration agent for waste incineration flue gas and preparation method of efficient denitration agent

A technology of waste incineration and denitration agent, which is applied in separation methods, chemical instruments and methods, gas treatment, etc., and can solve the problem of high denitration cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

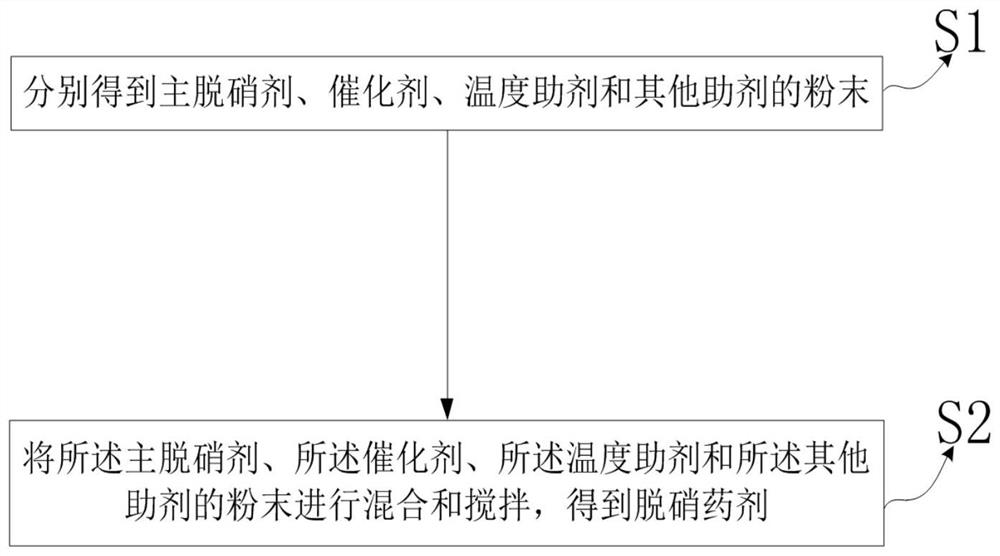

[0033] In the second aspect, the present application provides the preparation method of the denitration agent described in the first aspect, the method comprising the following steps:

[0034] Obtain the powder of main denitration agent, catalyst, temperature assistant and other assistants respectively;

[0035] The powders of the main denitration agent, the catalyst, the temperature aid and the other aids are mixed and stirred to obtain a denitration agent.

[0036] Specifically, weigh the main reducing agent, catalyst, auxiliary agent and other components in corresponding mass parts, and grind them into fine powders of 10-200 meshes respectively, and then add the ground fine powders to the high-speed paddle according to their respective mass parts. Mix in a blender. The linear speed of the paddle agitator is 20-40m / s, and the stirring time is 2-5 minutes, and finally a fine powdery high-efficiency denitrification agent of 10-200 mesh is obtained. The fineness of the denitr...

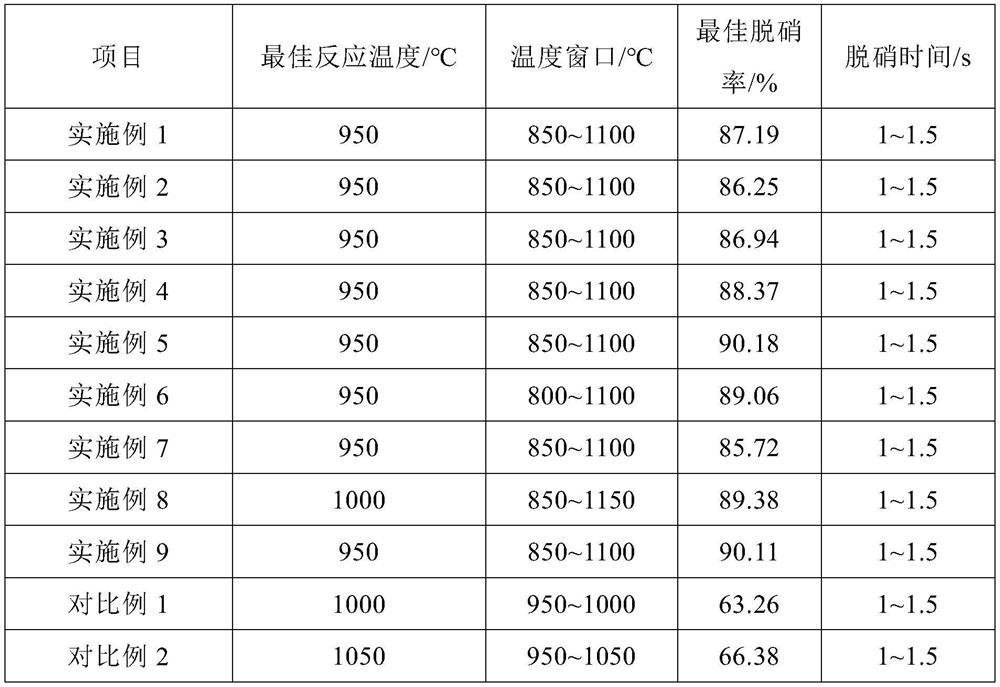

Embodiment 1

[0046]This embodiment provides an efficient denitrification agent for waste incineration flue gas. In terms of mass fraction, the components of the denitration agent include: urea particles: 91%, iron oxide agent: 3%, sodium carbonate agent: 3% % and potassium permanganate agent: 3%.

[0047] The preparation method of the denitration agent, the method comprises the following steps: respectively obtaining the powder of the main denitration agent, the catalyst, the temperature assistant and other assistants; Mixing and stirring with the powder of the other auxiliary agents to obtain the denitration agent; wherein, the fineness of the powder is 10-200 mesh. Specifically, the urea particles are ground into powder, and then the four substances are added to the high-speed paddle mixer for mixing. The linear speed of the paddle is set to 20m / s, and the stirring time is 5 minutes. Finally, the mixing is uniform. The powdered high-efficiency denitrification agent 1.

Embodiment 2

[0049] This embodiment provides an efficient denitrification agent for waste incineration flue gas. In terms of mass fraction, the components of the denitration agent include: urea particles: 85%, iron oxide agent: 5%, sodium carbonate agent: 5% % and Toner Potion: 5%. Others are the same as in Example 1, and finally form a uniformly mixed powdery high-efficiency denitration agent 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com