Micromolecular phosphorous acid-based water reducing agent as well as preparation method and application thereof

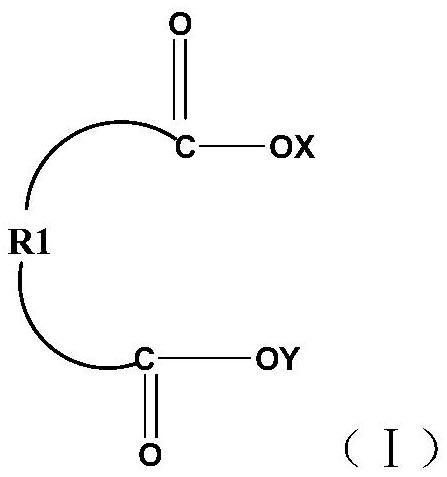

A technology of molecular phosphorous acid and phosphorous acid groups, which is applied in the field of preparation of small molecular phosphorous acid-based water reducers, can solve the problems of poor economy and high cost, and achieve low production energy consumption, strong coordination ability, good Effect of set retarding and slump holding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

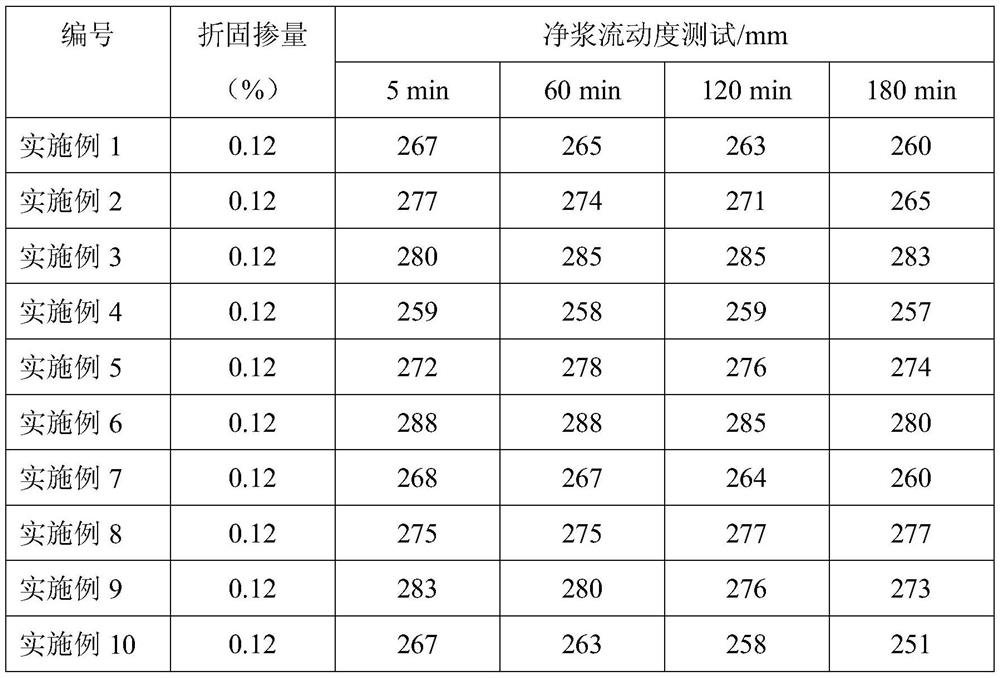

Examples

Embodiment 1

[0053] (1) Aminolysis reaction

[0054] 189.3 parts of tetraethylene pentamine and polyethylene glycol dicarboxylic acid derivative monoester (in structural formula I, R1 is an alkane with 2 carbon atoms, X and Y are H, -(CH) respectively. 2 CH 2 O) n -H, n=5) 405.6 parts were placed in a reaction kettle, the temperature was raised to 145° C., and the reaction was stirred for 10 h. After the reaction, a polyamine intermediate containing an amide structure was obtained.

[0055] (2) Phosphorylation reaction

[0056] Continue to add 492.0 parts of phosphorous acid into the above reaction kettle, add 189.3 parts of concentrated sulfuric acid under stirring, heat up to 90 ° C, hold for 5 min, then dropwise add 487.0 parts of 37wt% formaldehyde solution, install a condenser, heat under reflux for 10 hours, and cool to obtain a Phosphorylated polyamine intermediates.

[0057] (3) Preparation of water reducing agent

[0058] Continue to add 1200 parts of methoxy polyether (Mw 10...

Embodiment 2

[0060] (1) Aminolysis reaction

[0061] 116.2 parts of hexamethylene diamine and polyethylene glycol dicarboxylic acid derivative diester (in structural formula I, R1 is an alkene with 4 carbon atoms, X and Y are both -(CH 2 CH 2 O) n -H, n=11) 1167.6 parts were placed in a reaction kettle, the temperature was raised to 120° C., and the reaction was stirred for 7.5 h. After the reaction was completed, a polyamine intermediate containing an amide structure was obtained.

[0062] (2) Phosphorylation reaction

[0063] Continue to add 246 parts of phosphorous acid into the above reaction kettle, add 116.2 parts of methanesulfonic acid under stirring, heat up to 125 ° C, hold for 5min, then dropwise add 243.5 parts of 37wt% formaldehyde solution, install a condenser, heat under reflux for 13h, and cool to obtain a Phosphorylated polyamine intermediates.

[0064] (3) Preparation of water reducing agent

[0065] Continue to add 675 parts of methoxy polyether (Mw 3500, ethylene o...

Embodiment 3

[0067] (1) Aminolysis reaction

[0068] 103.2 parts of diethylenetriamine and polyethylene glycol dicarboxylic acid derivative monoester (in structural formula I, R1 is an alkane with 3 carbon atoms, X and Y are H, -(CH) respectively. 2 CH 2 O) n -H, n=4) 431.2 parts were placed in a reaction kettle, the temperature was raised to 136° C., and the reaction was stirred for 9 h. After the reaction, a polyamine intermediate containing an amide structure was obtained.

[0069] (2) Phosphorylation reaction

[0070] Continue to add 328 parts of phosphorous acid into the above reaction kettle, add 103.2 parts of trifluoromethanesulfonic acid under stirring, heat up to 110 ° C, hold for 5min, then dropwise add 324.6 parts of 37wt% formaldehyde solution, install a condenser, heat to reflux for 6h, and cool A phosphorylated polyamine intermediate is obtained.

[0071] (3) Preparation of water reducing agent

[0072] Continue to add 2800 parts of methoxy polyether (Mw 2000, copolymer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com