Non-oxide composite refractory materials for molten iron chute

A non-oxide and refractory material technology, applied in the field of refractory material manufacturing, can solve problems such as slag resistance, unfavorable iron corrosion, oxidative deterioration of steel fibers, and impact on service life, etc., to achieve short construction drying time, strong oxidation resistance, and fire resistance high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

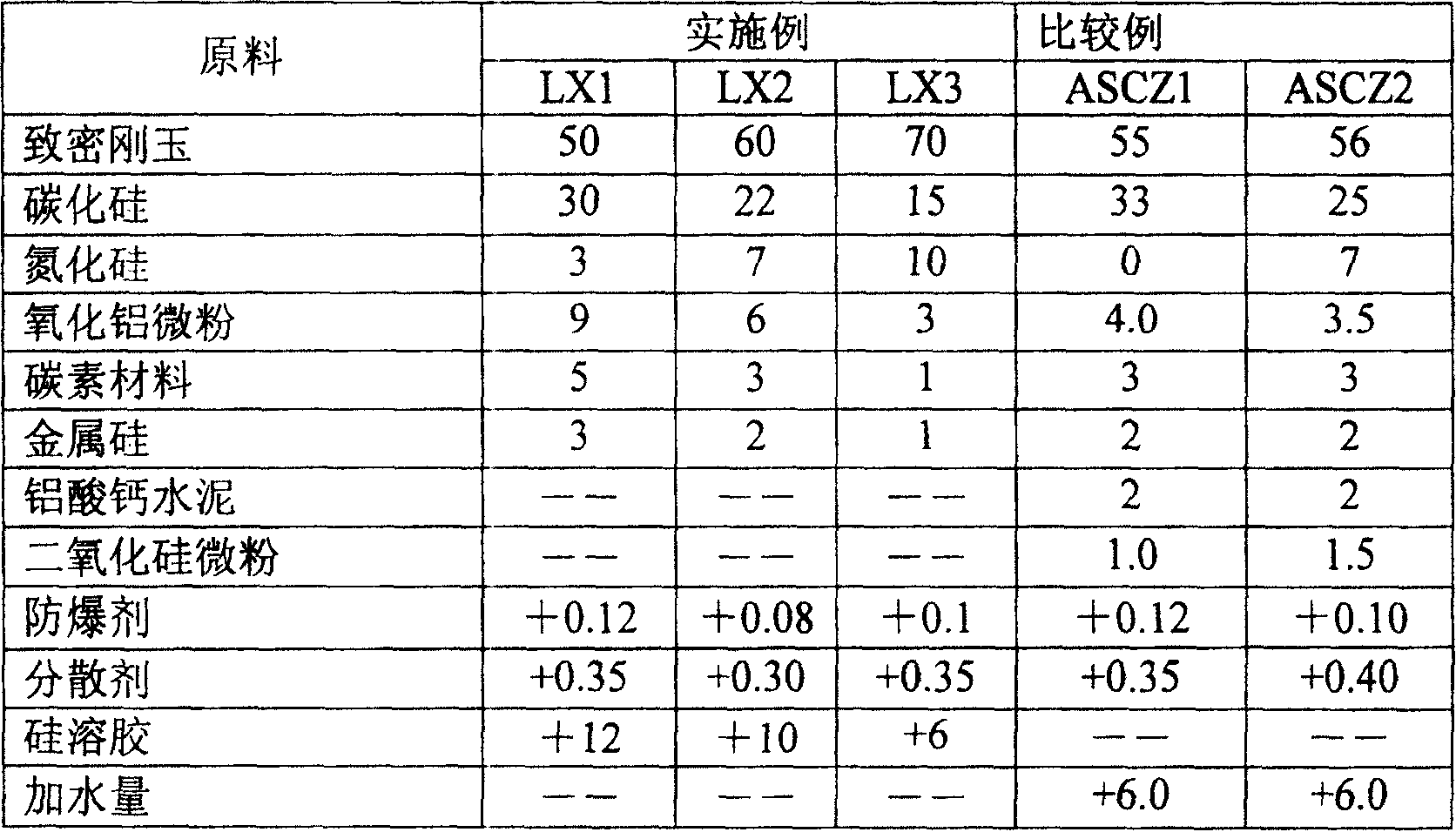

[0019] Table 1 is the main composition (wt%) of the examples of the invention and the comparative examples, and Table 2 is the performance of the samples of the examples of the invention and the comparative examples.

[0020] Table 1

[0021]

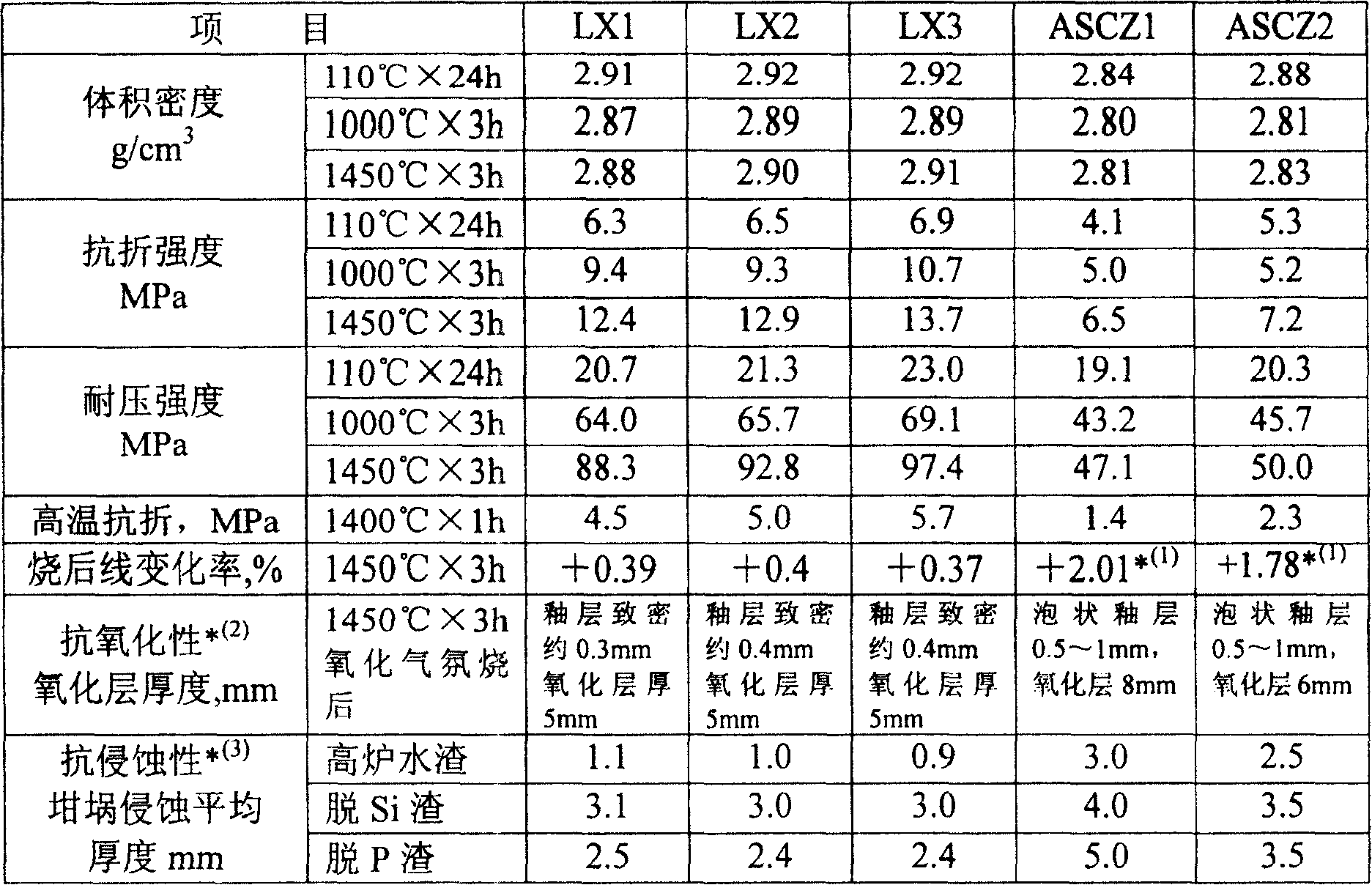

[0022] Table 2

[0023]

[0024] illustrate: * (1) After the sample was subjected to 1450°C × 3h in an oxidizing atmosphere, a bubble-like enamel layer with pores appeared on the surface of ASCZ1 and ASCZ2, and the surface was uneven. There is a slight error in measuring the size of the sample, which makes the data too large.

[0025] Note * (2) The oxidation resistance is evaluated by the thickness of the oxide layer of the sample. The thicker the oxide layer, the worse the oxidation resistance. The surface of the glaze layer of the sample of the embodiment is dense and high in strength after firing; while the surface of the glaze layer of the sample of the comparative example is bubbly, the strength is very low, and it is e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com