Lithium silicate glass ceramic, preparation method thereof and obtained prosthesis

A technology of glass ceramics and lithium silicate, which is applied in the field of dental materials, can solve problems such as incomplete die-casting, easy cracks, excessively high softening temperature and die-casting temperature, and achieve lower softening temperature and die-casting temperature, softening temperature and die-casting temperature. Reduced temperature, avoiding the effect of incomplete die casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

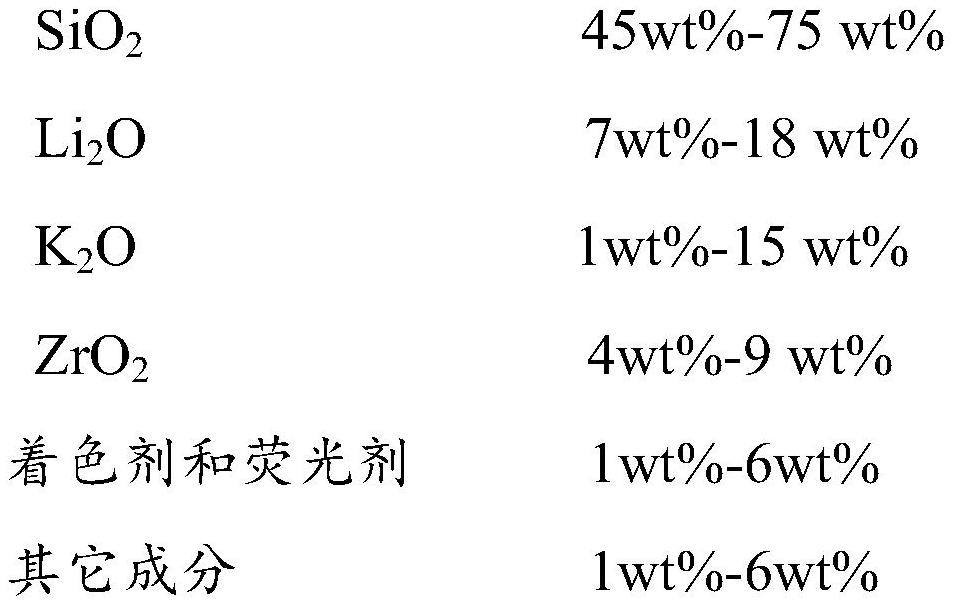

Method used

Image

Examples

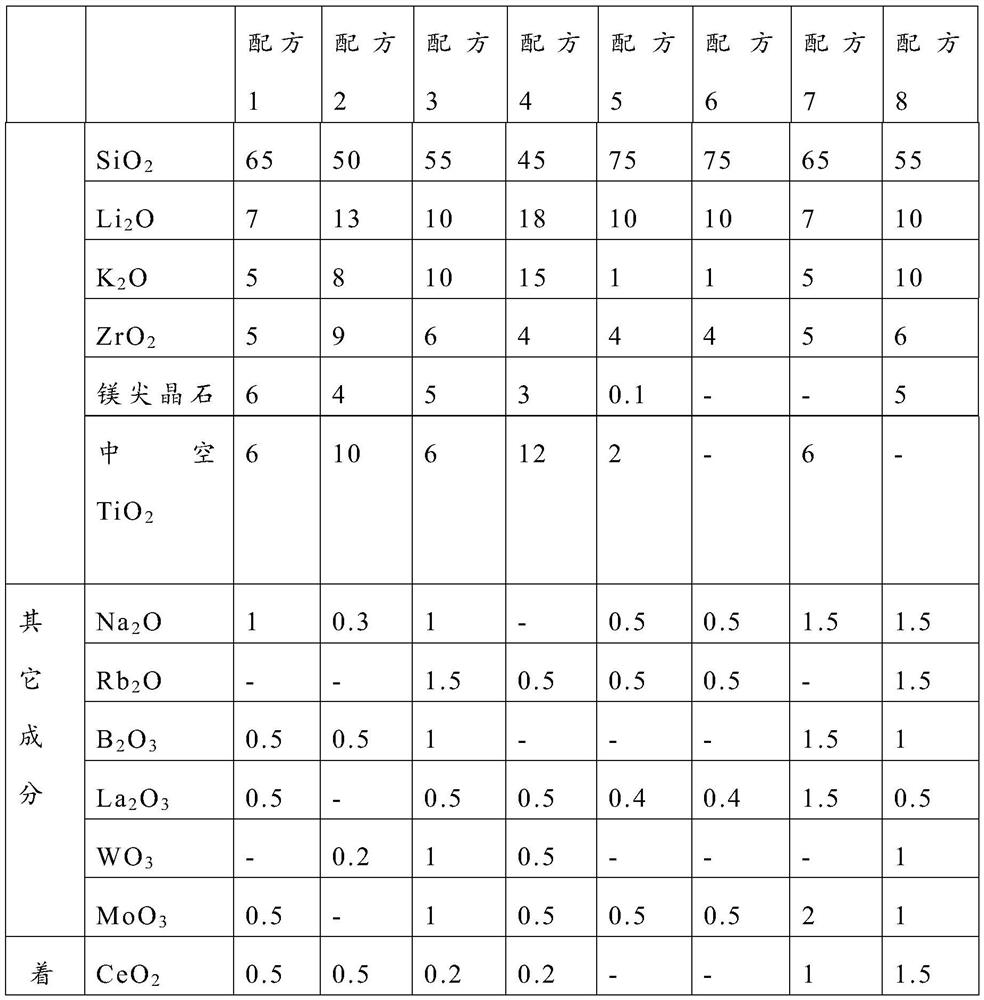

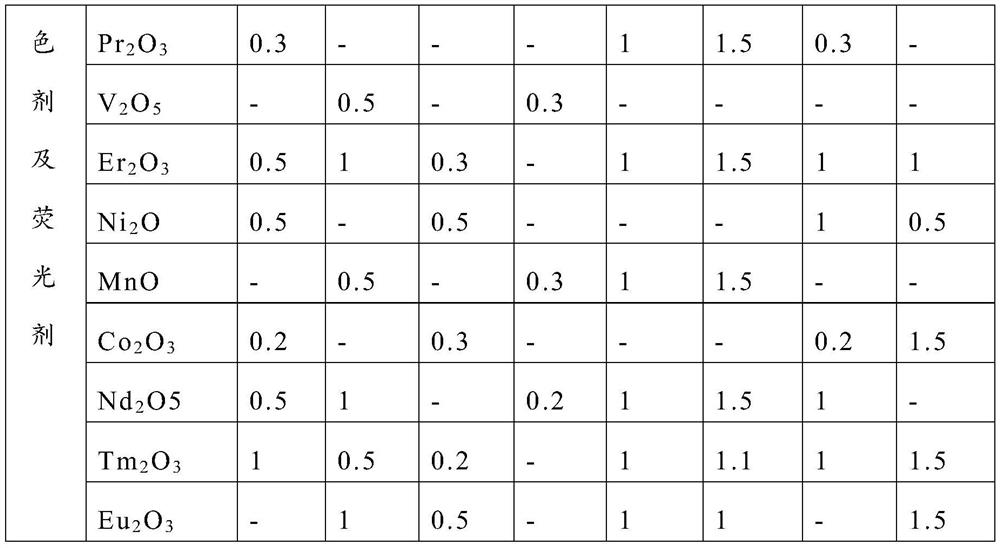

Embodiment 1

[0029] According to formula 1 in Table 1, the components are fully mixed and put into a platinum crucible, and the platinum crucible is placed in a heating furnace. melted, then poured into cold water to obtain a frit. The frit was heated at 1550 °C for 150 min to melt, and then cast into a mold to form a porcelain block. The ceramic block is heat-treated in a box furnace, the heat-treatment temperature is 800° C., and the heat-treatment time is 1 h to obtain lithium disilicate glass ceramics. Then, the lithium disilicate glass-ceramic is made into a lithium disilicate glass-ceramic restoration by a die-casting method, and the die-casting temperature is 650°C.

Embodiment 2

[0031] According to the formula 2 in Table 1, the components are fully mixed and put into the platinum crucible, the platinum crucible is put into the heating furnace, the heating temperature is controlled to be 1350 ° C, and the heating time is 120 min, so that the components are melted and uniform. melted, then poured into cold water to obtain a frit. The frit was heated at 1350°C for 120 min to melt, and then cast into a mold to form a ceramic block. The ceramic block is heat-treated in a box furnace, the heat-treatment temperature is 700° C., and the heat-treatment time is 2 hours to obtain lithium disilicate glass ceramics. Then, the lithium disilicate glass-ceramic is made into a lithium disilicate glass-ceramic restoration by a die casting method, and the die casting temperature is 730°C.

Embodiment 3

[0033] According to the formula 3 in Table 1, the components are fully mixed and put into a platinum crucible, the platinum crucible is put into a heating furnace, the heating temperature is controlled to be 1350 ° C, and the heating time is 120 min. melted, then poured into cold water to obtain a frit. The frit was heated at 1350°C for 120 min to melt, and then cast into a mold to form a ceramic block. The ceramic block is heat-treated in a box furnace, the heat-treatment temperature is 700° C., and the heat-treatment time is 2 hours to obtain lithium disilicate glass ceramics. Then, the lithium disilicate glass-ceramic was made into a lithium disilicate glass-ceramic restoration by die casting method, and the die casting temperature was 690°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com