PNIPAm gel device and method for regulating response temperature, light management and durability

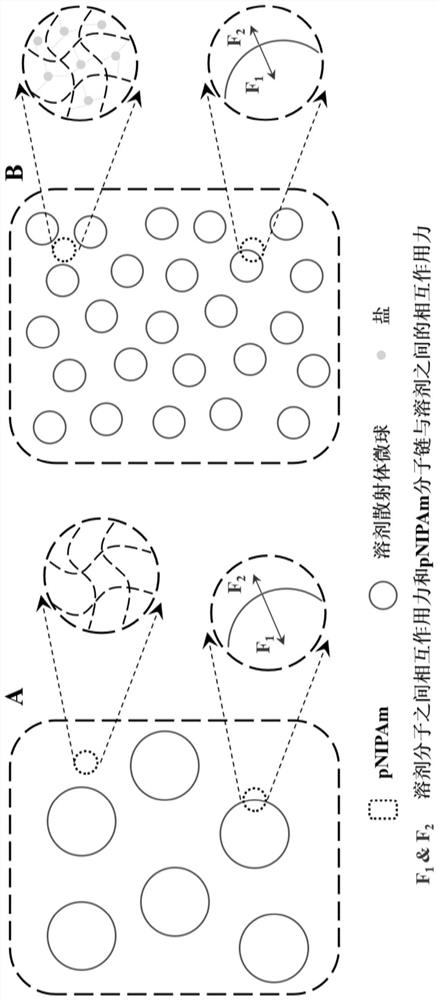

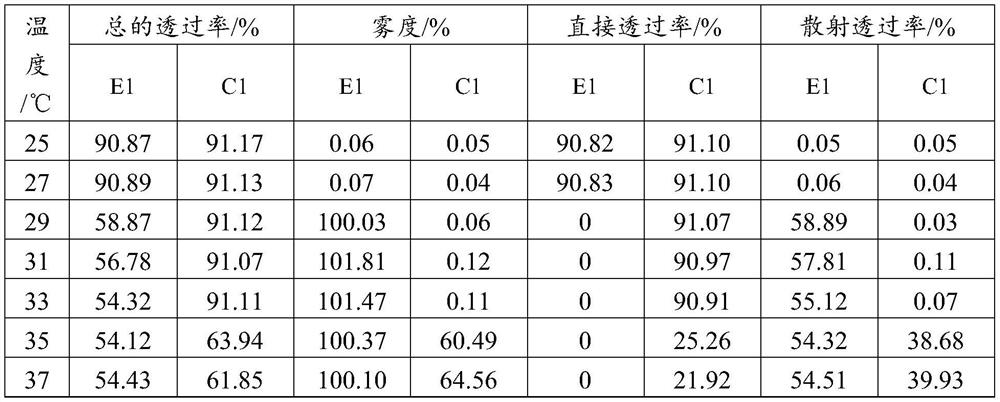

A light management and durability technology, applied in the field of optical materials, can solve the problems of difficult regulation, high polymer gel phase transition temperature, insufficient durability and stability of polymer gel, etc., to reduce the use of solvents, increase Interaction, reduce the effect of interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0055]第六,本发明提供了一种pNIPAm凝胶器件的制备方法,包括如下步骤:

[0056]NIPAm单体与水、第三组分、第四组分、交联剂、光引发剂共混得到混合溶液;通入惰性气体以排除氧气,并采用流延法制备不同厚度的薄膜器件前聚体,在光反应器中制备凝胶器件薄膜。

[0057]本发明中,具体是采用流延法制备凝胶薄膜。为了制备理想厚度的水凝胶膜,使用硅胶片(500nm)作为间隔片将两片薄玻璃片间隔连接。在UVLED反应器中进行pNIPAm凝胶的原位聚合。

[0058]本发明中,交联剂包括多烯类单体。

[0059]多烯类单体包括对甲基丙烯酸酐、丙烯酸酐、邻苯二甲酸二丙烯酯、二丙烯基氰基醋酸乙酯、或N,N-亚甲基双丙烯酰胺中的至少一种。

[0060]本发明中,光引发剂包括自由基引发剂。自由基引发剂包括偶氮二异丁腈(AIBN)、过氧化二苯甲酰(BPO)、甲基乙烯基酮、安息香、2,2-二乙氧基苯乙酮中的至少一种。

[0061]本发明中,水与NIPAm单体的质量比为1:0.01~0.5;NIPAm单体与交联剂的质量比为1:0.0001~0.5;NIPAm单体与光引发剂的质量比为1:0.0001~0.05。

[0062]在UVLED反应器中进行pNIPAm凝胶的原位聚合,反应时间为1~30min,功率为1~50%,温度为0~30℃(氮气氛围)。

[0063]第七,本发明提供了一种如前述的制备方法得到的pNIPAm凝胶器件。

[0064]<实施例>

Example Embodiment

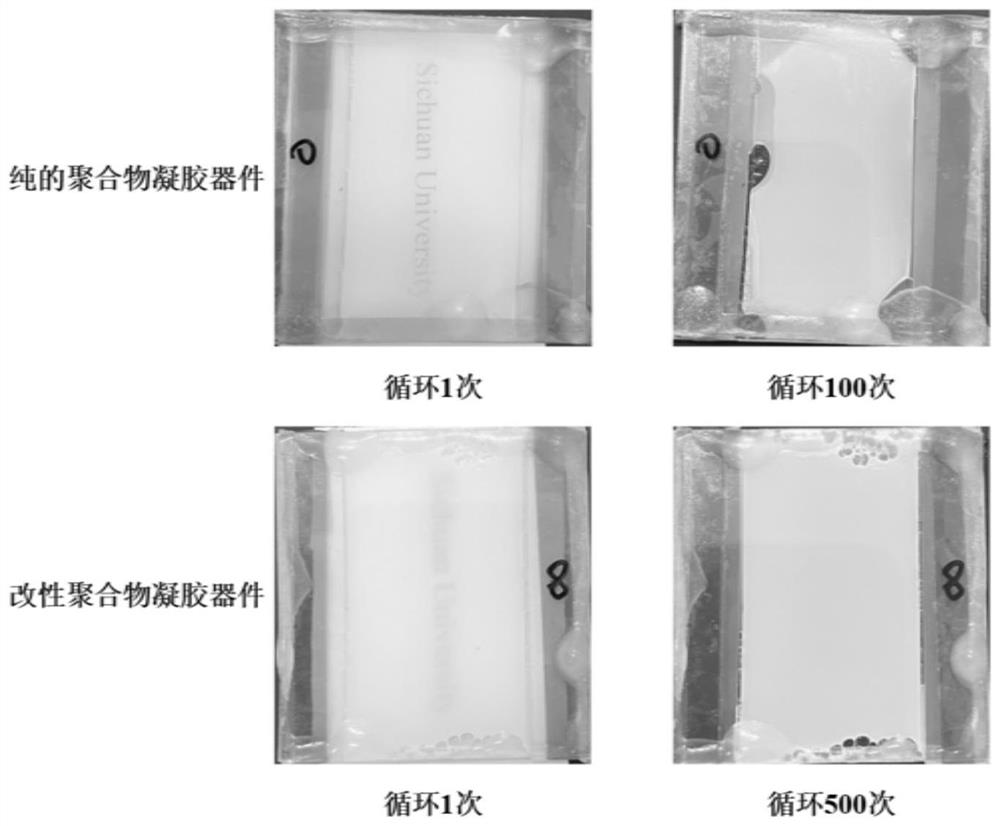

[0065]实施例1

[0066]一种改性pNIPAm凝胶器件的制备方法,包括如下步骤:

[0067](1)将N-异丙基丙烯酰胺水凝胶1g,氯化钠0.45g,溶于去离子水18.8mL和乙醇1.2mL的混合溶液中;用该混合溶液溶解N,N-亚甲基双丙烯酰胺10mg和2,2-二乙氧基苯乙酮7.5μL,高速搅拌1h;然后向混合溶液中持续通入氮气10min;本实施例中,第三组分为乙醇,第四组分为氯化钠。

[0068](2)采用流延法制备凝胶薄膜,使用硅胶片(500nm)作为间隔片将两片薄玻璃片间隔连接。在UVLED反应器中进行pNIPAm凝胶的原位聚合,反应时间为10min,功率为12%,温度为20℃(氮气氛围)。

Example Embodiment

[0069]实施例2

[0070]一种改性pNIPAm凝胶器件的制备方法,包括如下步骤:

[0071](1)将N-异丙基丙烯酰胺水凝胶1g,四氟硼酸钠0.65g,溶于去离子水18.8mL和乙醇1.2mL的混合溶液中;用该混合溶液溶解N,N-亚甲基双丙烯酰胺10mg和2,2-二乙氧基苯乙酮7.5μL,高速搅拌1h;然后向混合溶液中持续通入氮气10min;本实施例中,第三组分为乙醇,第四组分为四氟硼酸钠。

[0072](2)采用流延法制备凝胶薄膜,使用硅胶片(500nm)作为间隔片将两片薄玻璃片间隔连接。在UVLED反应器中进行pNIPAm凝胶的原位聚合,反应时间为10min,功率为12%,温度为20℃(氮气氛围)。

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com