Zirconia ceramic slurry, preparation method thereof, false tooth and false tooth preparation method

A technology of zirconia ceramics and zirconia, which can be used in pharmaceutical formulations, dental preparations, compression molding cups, etc., and can solve problems such as unsightly appearance, large porosity after sintering, and insufficient hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a zirconia ceramic slurry, the raw materials include yttria-stabilized zirconia, a dispersant, an ultraviolet absorber, a photoinitiator, a photosensitive resin, a toughening agent, a binding agent, a defoaming agent, and a silane coupling agent.

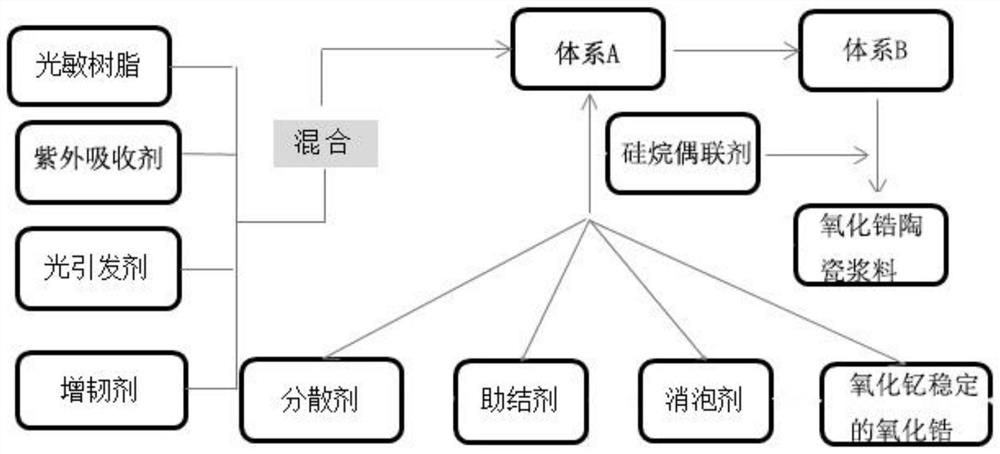

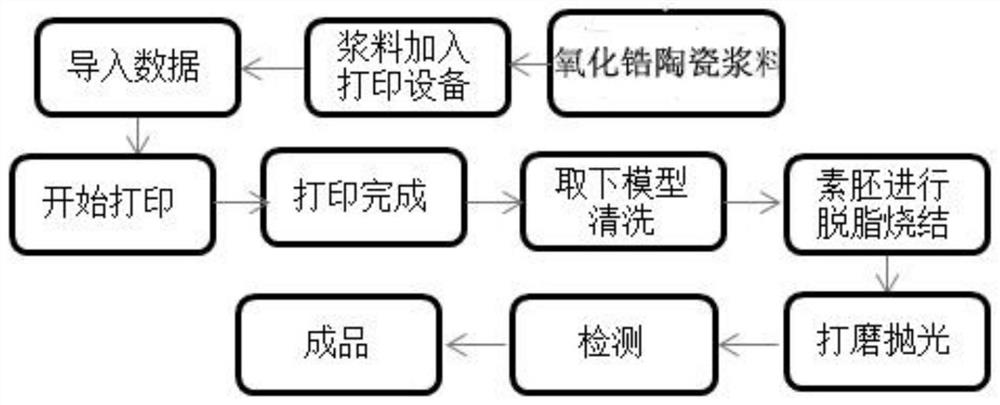

[0035] This embodiment provides a method for preparing the above-mentioned zirconia ceramic slurry, such as figure 1 shown, including:

[0036] Step 1. Ball mill mixing 40g photosensitive resin hydroxyethyl methacrylate, 9.2g toughening agent zinc oxide, 4g ultraviolet absorber UV-329 and 6g photoinitiator DAROCUR 1173 for 12h to obtain system A; the ball milling speed is 300r / min; the particle size of the yttria-stabilized zirconia is 70 nm to 80 nm;

[0037] Step 2: Ball milling the system A described in step 1, 6g dispersant Disperbyk-103, 22.8g coagulant magnesium oxide and 130g yttria-stabilized zirconia for 9h, add 5.2g defoamer H1125, and continue ball milling until the viscosity is less tha...

Embodiment 2

[0040] This embodiment provides a zirconia ceramic slurry, the raw materials include yttria-stabilized zirconia, a dispersant, an ultraviolet absorber, a photoinitiator, a photosensitive resin, a toughening agent, a binding agent, a defoaming agent, and a silane coupling agent.

[0041] The present embodiment provides a method for preparing the above-mentioned zirconia ceramic slurry, comprising:

[0042] Step 1, ball milling 36g photosensitive resin hydroxyethyl methacrylate, 6g toughening agent zinc oxide, 2g ultraviolet absorber UV-329 and 9g photoinitiator DAROCUR 1173 for 10h to obtain system A; the ball milling speed is 280r / min; the particle size of the yttria-stabilized zirconia is 50 nm to 60 nm;

[0043] Step 2: Ball milling the system A, 4g dispersant Disperbyk-103, 18g coagulant magnesia and 120g yttria-stabilized zirconia described in step 1 for 10h, add 4.8g defoamer H1125, and continue ball milling until viscosity≤150mpa. s, to obtain system B; the ball-milli...

Embodiment 3

[0046] This embodiment provides a zirconia ceramic slurry, the raw materials include yttria-stabilized zirconia, a dispersant, an ultraviolet absorber, a photoinitiator, a photosensitive resin, a toughening agent, a binding agent, a defoaming agent, and a silane coupling agent.

[0047] The present embodiment provides a method for preparing the above-mentioned zirconia ceramic slurry, comprising:

[0048] Step 1. Ball milling 52g photosensitive resin hydroxyethyl methacrylate, 12g toughening agent zinc oxide, 6g ultraviolet absorber UV-329 and 10.4g photoinitiator DAROCUR 1173 for 15h to obtain system A; the ball milling speed is 350r / min; the particle size of the yttria-stabilized zirconia is 90 nm to 100 nm;

[0049] Step 2, ball milling system A, 8g dispersant Disperbyk-103, 10g coagulant magnesia and 150g yttria-stabilized zirconia described in step 1 for 8h, add 4.16g defoamer H1125, and continue ball milling until viscosity≤150mpa. s, to obtain system B; the ball-mill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com