Anaerobic ammonia oxidation deep denitrification method for municipal sewage

A technology of anaerobic ammonium oxidation and urban sewage, applied in the field of deep denitrification of urban sewage anaerobic ammonium oxidation, can solve the problems of inability to meet discharge requirements, low nitrogen removal rate, increase of external carbon sources, etc., to promote resource utilization Utilization, high economic benefits, and the effect of reducing carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

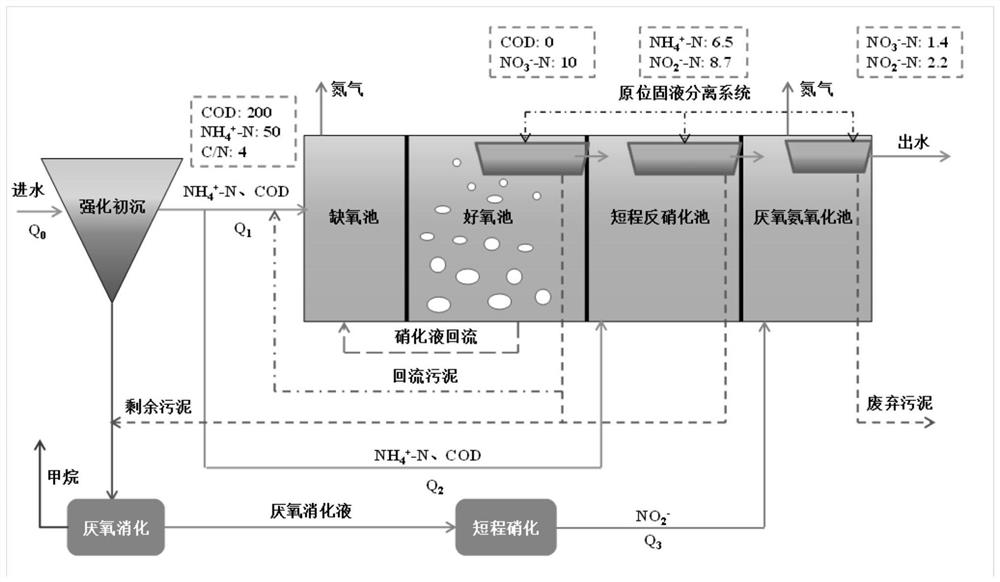

[0062] In this embodiment, after the urban sewage undergoes enhanced primary sedimentation, the ammonia nitrogen concentration in the enhanced primary sedimentation effluent is 50 mg / L, and the C / N ratio is 4. The specific operation process is as follows: figure 2 shown, including the following steps:

[0063] 1. Set the flow to Q 0 The enhanced primary settling effluent is split, and the main stream flow is Q 1 , the tributary flow is Q 2 , sewage contains COD and ammonia nitrogen.

[0064] 2. Mainstream Q 1 Enter the anoxic tank and aerobic tank to carry out the nitrification and denitrification process. The nitrification and denitrification bacteria make full use of the organic matter in the sewage to carry out nitrification and denitrification through the backflow of the nitrification solution to obtain nitrogen gas and nitrification and denitrification effluent. The nitrification and denitrification effluent contains the remaining nitrate. The concentration of nitrat...

Embodiment 2

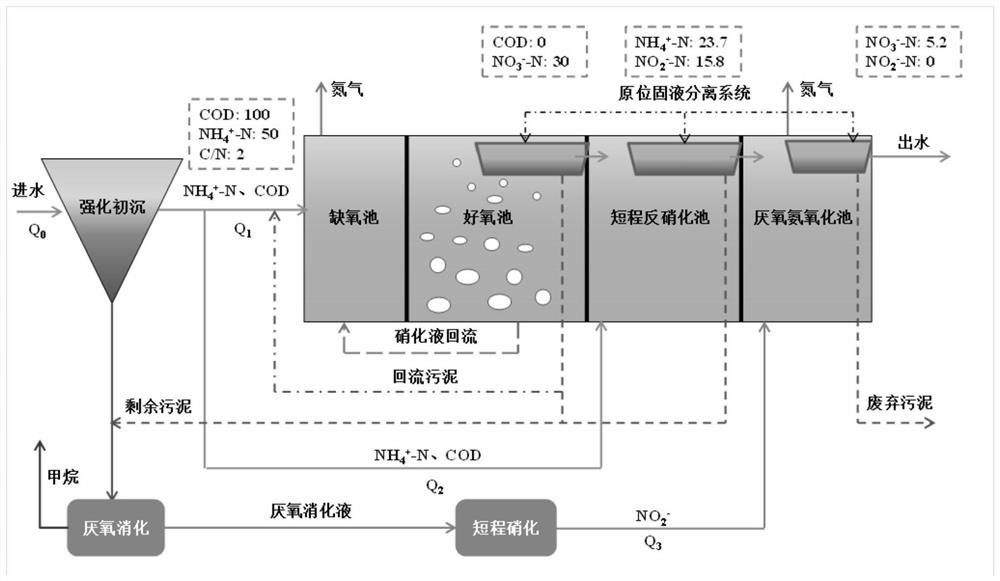

[0073] In this embodiment, after the urban sewage undergoes enhanced primary sedimentation, the ammonia nitrogen concentration in the enhanced primary sedimentation effluent is 50 mg / L, and the C / N ratio is 2. The specific operation process is as follows: figure 2 shown, including the following steps:

[0074] 1. Set the flow to Q 0 The enhanced primary settling effluent is split, and the main stream flow is Q 1 , the tributary flow is Q2 , sewage contains COD and ammonia nitrogen.

[0075] 2. Mainstream Q 1 Enter the anoxic tank and aerobic tank for nitrification and denitrification process, through the backflow of nitrification solution, the nitrification and denitrification bacteria make full use of the organic matter in the sewage to carry out nitrification and denitrification, and obtain nitrogen and nitrification and denitrification effluent. The nitrification and denitrification effluent contains the remaining nitrate. The concentration of nitrate nitrogen is 30 mg / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com