Preparation method of high-flame-retardant fireproof cable

A fire-resistant cable and high flame-retardant technology, which is applied in the direction of cable/conductor manufacturing, fire-resistant coatings, insulating cables, etc., can solve the problem of weak adhesion between fire-proof mud and inner cables, insufficient fluidity of fire-proof mud, and affecting flame retardancy Fire prevention effect and other issues to achieve the effect of reducing the risk of being burned, improving the bonding effect, and preventing evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

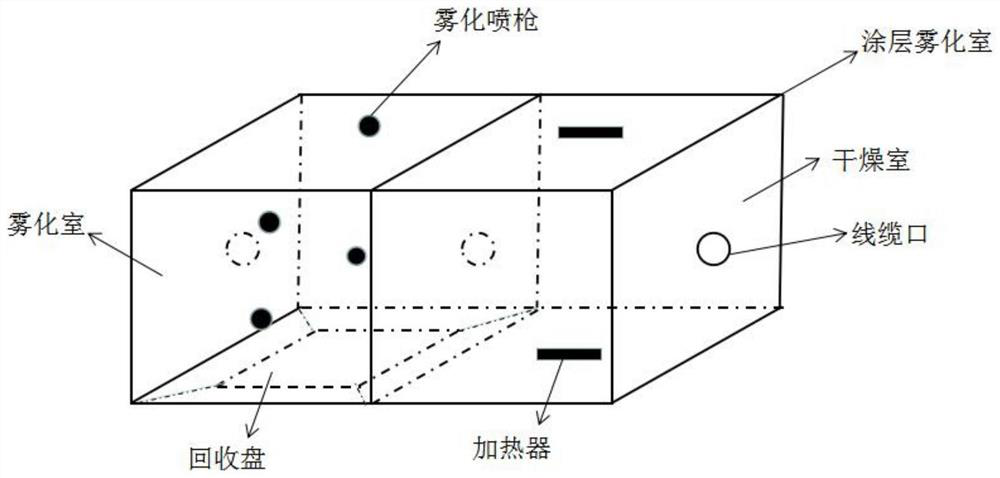

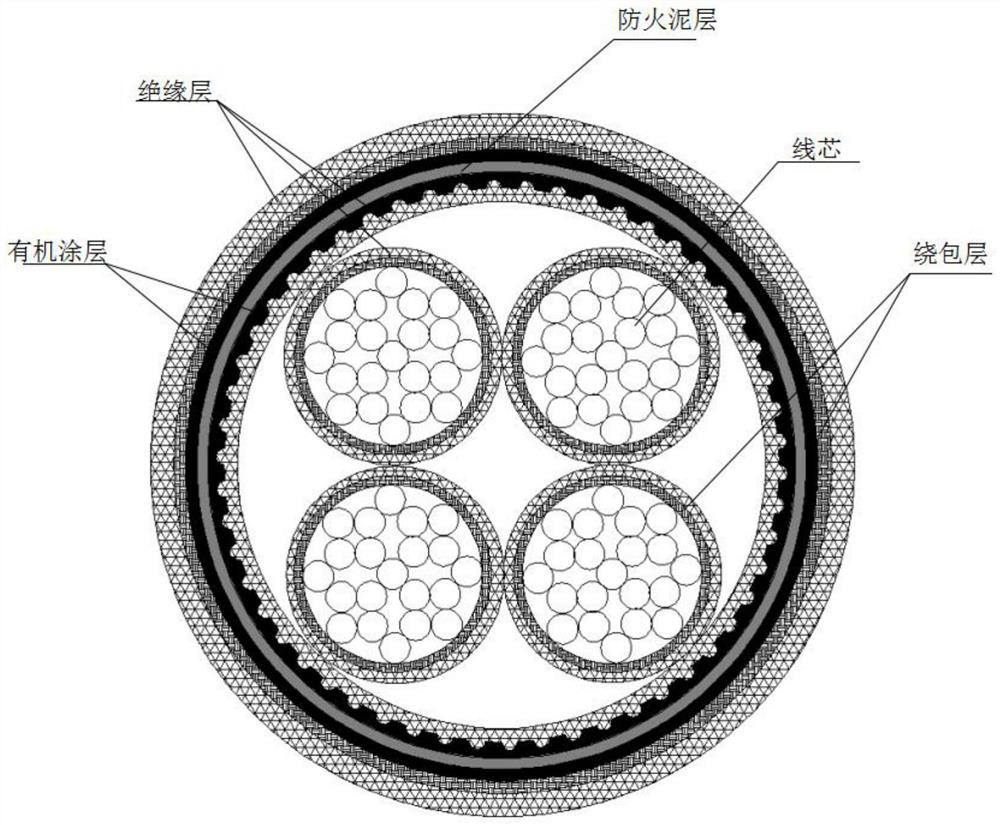

[0029] The structural schematic diagram of the high flame retardant fireproof cable to be prepared in this embodiment, such as figure 1 shown:

[0030] 1) Wire core drawing and stranding: use oxygen-free copper rod to wire it to a wire core with a diameter of 1.47mm, and then twist 21 wire cores after drawing into a wire bundle to obtain a stranded wire;

[0031] 2) Stranded wire insulation: The stranded wire obtained in step 1) is wrapped with 1 layer of polyester tape and 1 layer of non-woven fabric (the wrapping rate is 25%), and then extruded for insulation, and the insulating material is polyethylene, get insulated stranded wire;

[0032] 3) Cable twisting: twist the 4 insulated stranded wires in step 2), and extrude the insulation again. The insulating material is polyethylene. During the extrusion process, the insulation surface needs to be uniformly extruded. Protrusion (increase the contact area with the subsequent organic coating and insulating layer) to obtain a c...

Embodiment 2

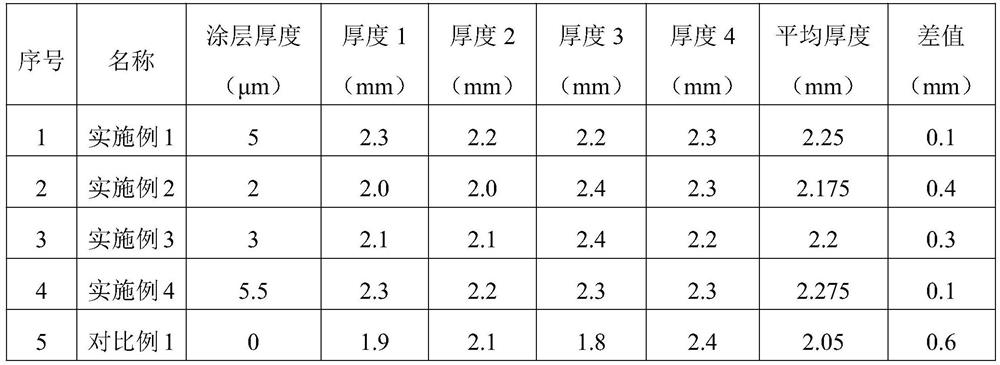

[0043] This example is a high flame retardant fireproof cable, the pressure of the spray gun in the coating atomization chamber is 0.1Mpa, the thickness of the prepared organic coating is 2μm, and other preparation methods are the same as those in Example 1.

Embodiment 3

[0045]This example is a high flame retardant fireproof cable, the pressure of the spray gun in the coating atomization chamber is 0.15Mpa, the thickness of the prepared organic coating is 3 μm, and other preparation methods are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com