FRP/steel composite constraint UHPC anchor plate and preparation method thereof

A technology of anchor plates and composite materials, which is applied in the direction of manufacturing tools, wind power generation, building components, etc., can solve the problems of heavy weight and disadvantages of anchors, and achieve the effect of reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

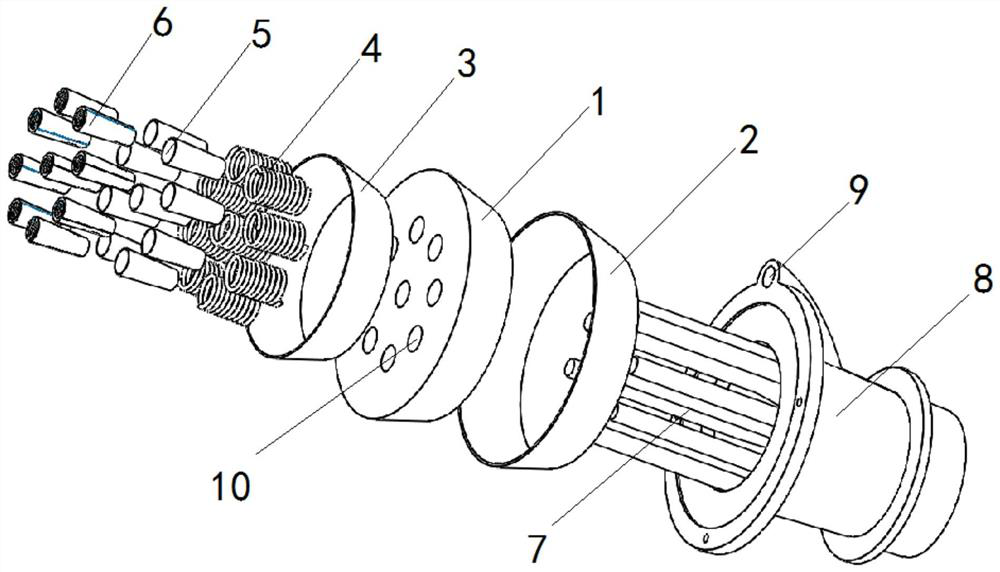

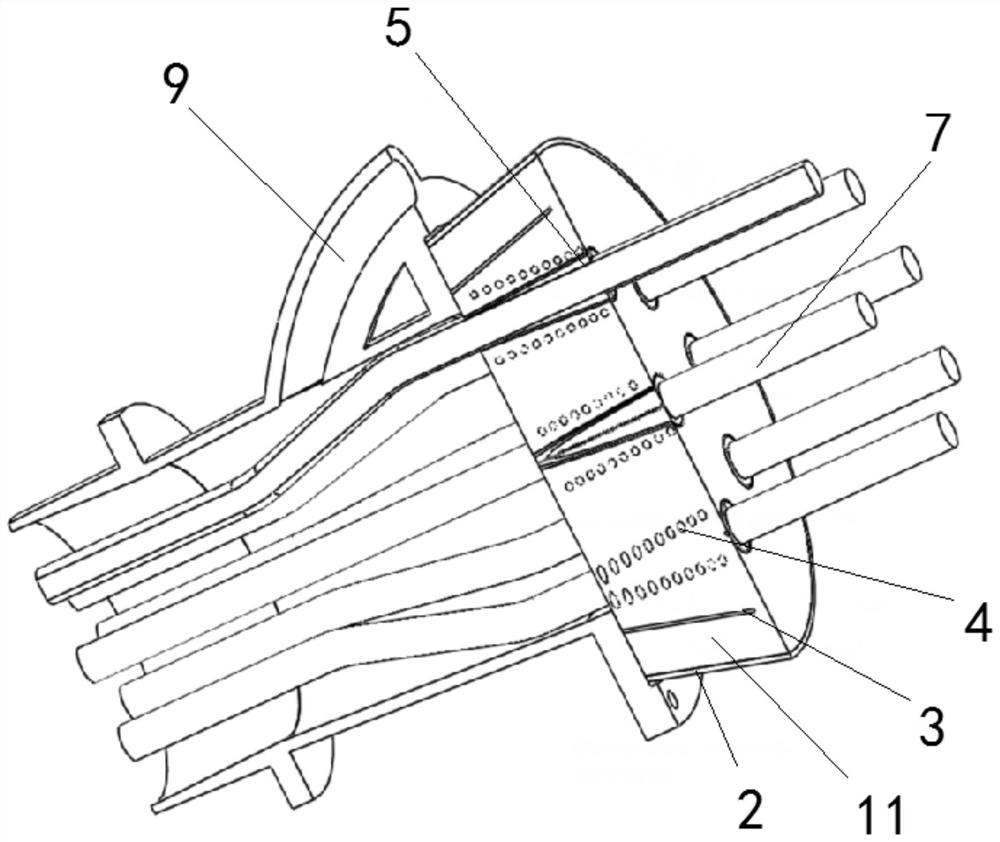

[0032] Specific implementation mode 1: refer to Figure 1 to Figure 4 Illustrating this embodiment, this embodiment provides a FRP / steel composite restraint UHPC porous anchor plate, the porous anchor plate includes a UHPC main body 1, an outer layer FRP restraint pipe 2, a restraint steel pipe 3, and N restraint protection clip bodies, N is a positive integer;

[0033] The UHPC main body 1, the outer layer FRP restraint pipe 2 and the restraint steel pipe 3 are coaxially arranged, the UHPC main body 1 is a truncated cone-shaped structure, and one end of the UHPC main body 1 is uniformly machined with an anchor plate anchor hole 10, and the outer layer FRP restraint pipe 2 Both the restraining steel pipe 3 and the constraining steel pipe 3 are in the shape of a truncated cylinder. The outer layer FRP restraining pipe 2 is sleeved on the outer side of the UHPC main body 1, and the outer layer FRP restraining pipe 2 is fitted with the outer surface of the UHPC main body 1. The r...

specific Embodiment approach 2

[0040] Specific implementation two: refer to Figure 1 to Figure 4 This embodiment is described. This embodiment further defines the anchor plate anchor hole 10 described in the specific embodiment 1. In this embodiment, the anchor plate anchor hole 10 is a tapered hole, and the anchor plate anchor hole 10 has a large opening. The end is arranged on the large mouth end of the UHPC main body 1 , and the small mouth end of the anchor hole 10 of the anchor plate is arranged on the small mouth end of the UHPC main body 1 . Other components and connection methods are the same as in the first embodiment.

specific Embodiment approach 3

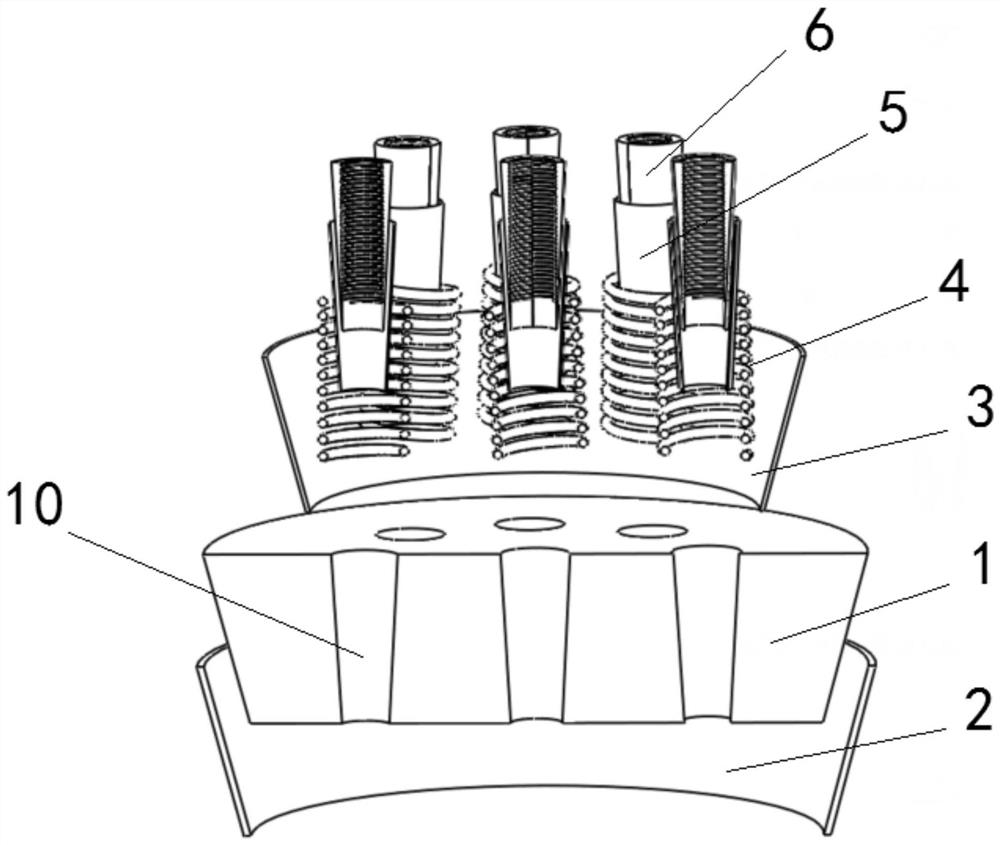

[0041] Specific implementation mode three: refer to Figure 1 to Figure 4 This embodiment is described. This embodiment further defines the restraint protection clip described in the second embodiment. In this embodiment, the restraint protection clamp specifically includes a restraining spiral steel bar 4, a protective cone tube 5 and an anchor. The clip 6, the restraining spiral steel bar 4, the protective cone tube 5 and the anchor clip 6 are sequentially set from outside to inside, and the protective cone tube 5 is arranged in cooperation with the anchor hole 10 of the anchor plate. Other components and connection methods are the same as in the first embodiment.

[0042] In this embodiment, there are spiral restraint stirrups 4 outside the protective cone pipe 5, the protective cone pipe 5 provides surface penetration and extrusion protection for the anchor hole, the taper of the protective cone pipe 5 is consistent with the relevant parameters of the clip selected in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com