High-thermal-resistant self heat-preservation building block of energy-saving building and preparation process of high-thermal-resistant self heat-preservation building block

A self-insulating block and high thermal resistance technology, applied in the field of building materials, can solve the problems of unsatisfactory compressive strength and restrictions on the use of blocks, and achieve the effects of strong rain erosion resistance, easy operation, and low sugar content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Table 1 is each component and quality of a kind of energy-saving building high thermal resistance self-insulation block of embodiment 1

[0040] components mass (kg) components mass (kg) cement 50 rock wool 8 fly ash 45 straw fiber 6 gravel 10 Sodium lignosulfonate 2 Polystyrene particles 3 water 10 expanded perlite 2

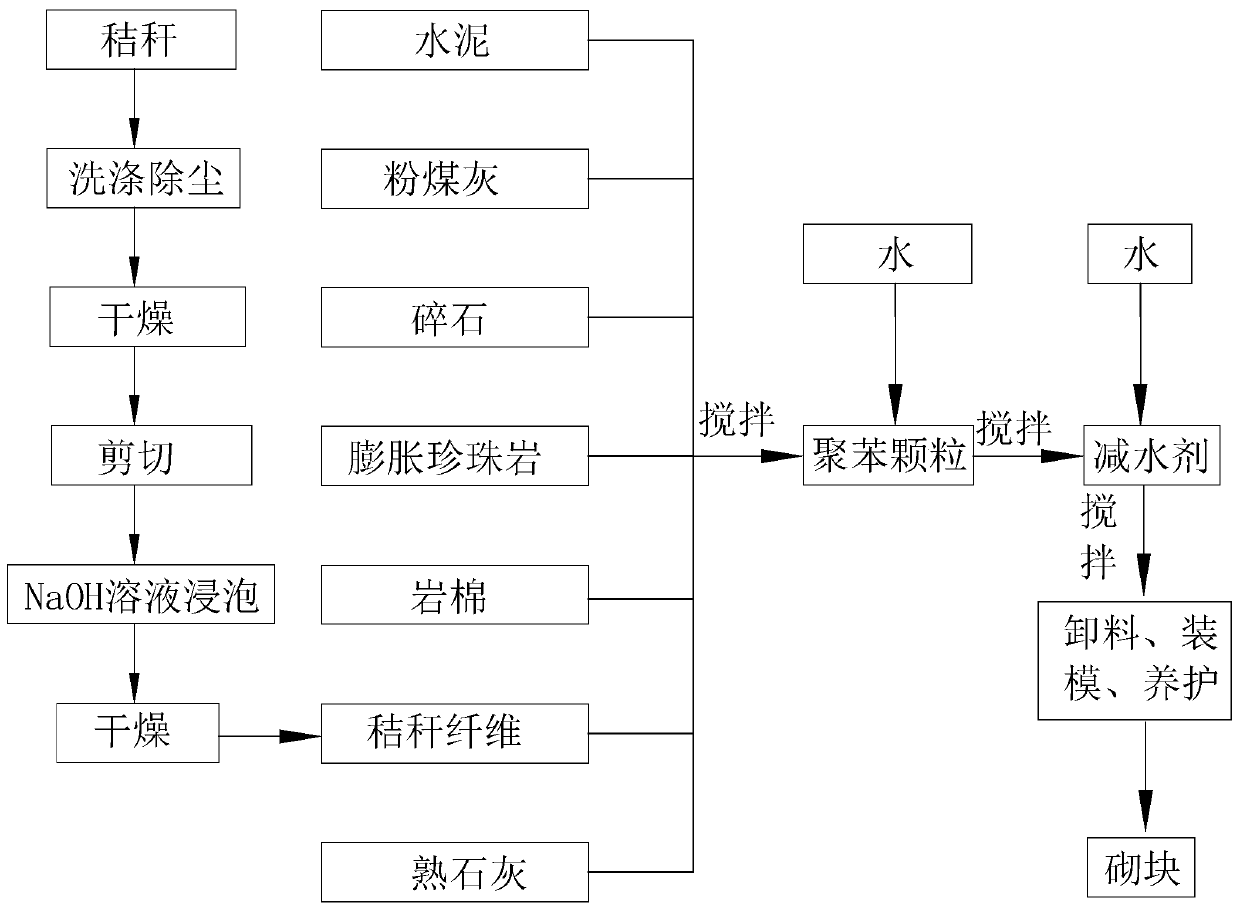

[0041] refer to figure 1, wherein the preparation method of straw fiber is as follows: 1) the straw is washed and dedusted, and then dried; 2) after the straw is dried, the straw is cut into a length of 3-5 mm; 3) the cut straw is soaked in a mass fraction of Stir the straw in 10% sodium hydroxide solution for 5 to 8 hours, and then let it stand for 10 to 12 hours; 4) The straw treated in step 3) is dried to obtain the straw fiber.

[0042] The preparation process of the energy-saving building high thermal resistance self-insulation block specifically includes the following steps:

[004...

Embodiment 2

[0048] Table 2 is each component and quality of a kind of energy-saving building high thermal resistance self-insulation block of embodiment 2

[0049] components mass (kg) components mass (kg) cement 60 rock wool 6 fly ash 40 straw fiber 8 gravel 13 calcium lignosulfonate 3 Polystyrene particles 5 water 12 expanded perlite 3

[0050] Wherein the preparation method of straw fiber is with embodiment 1.

[0051] The preparation process of the high thermal resistance self-insulating block of the energy-saving building is the same as that in Example 1.

Embodiment 3

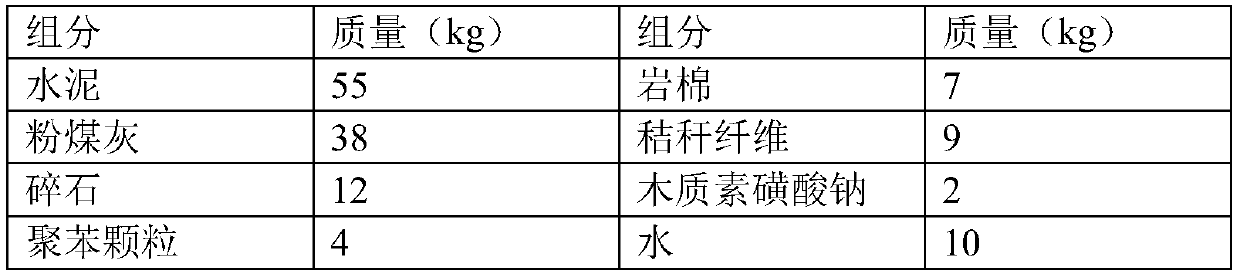

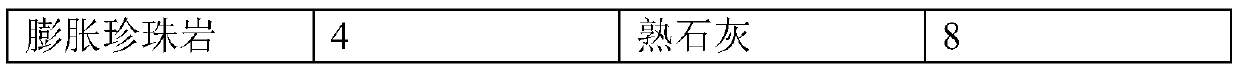

[0053] Table 3 is each component and quality of a kind of energy-saving building high thermal resistance self-insulation block of embodiment 3

[0054] components mass (kg) components mass (kg) cement 70 rock wool 5 fly ash 35 straw fiber 10 gravel 15 Sodium lignosulfonate 4 Polystyrene particles 6 water 15 expanded perlite 5

[0055] Wherein the preparation method of straw fiber is with embodiment 1.

[0056] The preparation process of the energy-saving building high thermal resistance self-insulation block specifically includes the following steps:

[0057] Step 1. Weigh each material according to the formula quantity, mix cement, fly ash, crushed stone, expanded perlite, rock wool, straw fiber and slaked lime evenly, then add half of the formula quantity of water, and stir evenly;

[0058] Step 2, continue to add the polyphenylene particles of formula quantity to step 1 and continue to stir until the polysty...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com