High-strength lightweight porous concrete and preparation method thereof

A porous concrete, lightweight technology, applied in the field of concrete, can solve problems such as low concrete strength and inability to meet engineering needs, and achieve the effects of reducing porosity, firm interface bonding, and alleviating stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

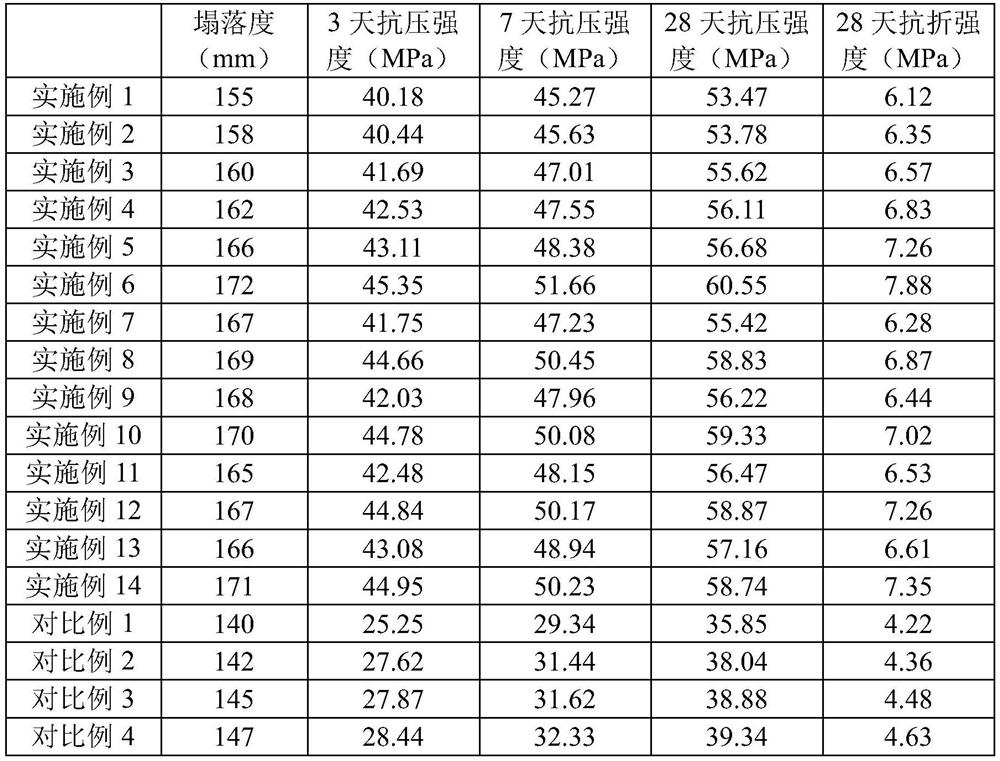

Examples

Embodiment 1

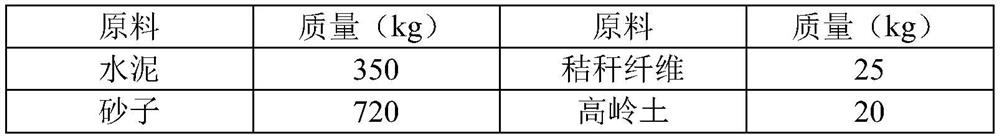

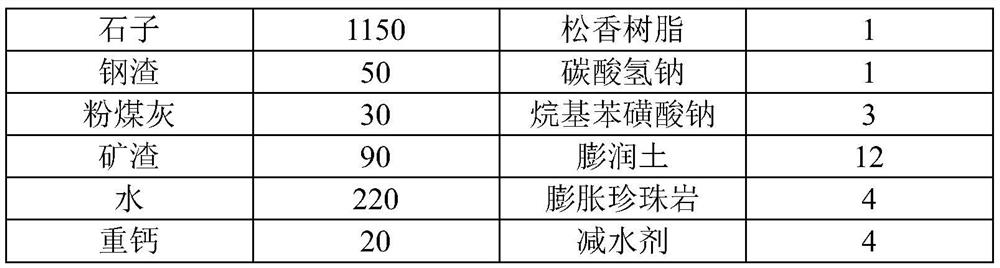

[0038] Table 1 is the raw material and quality of a kind of high-strength lightweight porous concrete of embodiment 1

[0039]

[0040]

[0041] Among them, the fineness modulus of sand is 2.8, the particle size of stone is 5-10mm, and the particle size of steel slag is 10-15um;

[0042] A preparation method of high-strength lightweight porous concrete, specifically comprising the following steps:

[0043] S1. Foaming: add 1kg rosin resin, 1kg sodium bicarbonate and 3kg sodium alkylbenzene sulfonate into 110kg water to dilute to form a foaming liquid, and foam it through an air compression foaming machine to obtain a homogeneous, stable and delicate foam Foam, foam density 50kg / m 3 ;

[0044] S2, pulping: 350kg cement, 720kg sand, 1150kg gravel, 50kg steel slag, 30kg fly ash, 90kg slag, 110kg water, 20kg heavy calcium, 25kg straw fiber, 20kg kaolin, 12kg bentonite, 4kg expanded perlite and 4kg reduced The water agent is added into the mixing tank, and stirred evenly t...

Embodiment 2

[0047] Table 2 is the raw material and quality of a kind of high-strength lightweight porous concrete of embodiment 2

[0048] raw material mass (kg) raw material mass (kg) cement 400 straw fiber 30 sand 750 Kaolin 25 pebbles 1100 Rosin resin 2 steel slag 60 sodium bicarbonate 2 fly ash 50 Sodium alkylbenzene sulfonate 4 slag 100 polyacrylamide 12 water 280 expanded perlite 6 heavy calcium 25 Superplasticizer 3

[0049] Among them, the fineness modulus of sand is 3.0, the particle size of stone is 10-20mm, and the particle size of steel slag is 15-20um;

[0050] A preparation method of high-strength lightweight porous concrete, specifically comprising the following steps:

[0051] S1. Foaming: add 2kg rosin resin, 2kg sodium bicarbonate and 4kg sodium alkylbenzene sulfonate to 140kg water to dilute it into a foaming liquid, and foam it through an air compression foaming machine to obtain ...

Embodiment 3

[0055] Table 3 is the raw material and quality of a kind of high-strength lightweight porous concrete of embodiment 3

[0056] raw material mass (kg) raw material mass (kg) cement 360 Kaolin 15 sand 800 Rosin resin 3 pebbles 1200 sodium bicarbonate 1.5 steel slag 70 Sodium alkylbenzene sulfonate 5 fly ash 50 Bentonite 6 slag 110 polyacrylamide 5 water 250 Cellulose ether 7 heavy calcium 30 expanded perlite 8 straw fiber 35 Superplasticizer 5

[0057] Among them, the fineness modulus of sand is 3.2, the particle size of stone is 20-30mm, and the particle size of steel slag is 20-25um;

[0058] A preparation method of high-strength lightweight porous concrete, specifically comprising the following steps:

[0059] S1. Foaming: Add 3kg rosin resin, 1.5kg sodium bicarbonate and 5kg sodium alkylbenzene sulfonate into 125kg water to dilute it into a foaming liquid, and foam it through a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com