Beam upturned joint structure with good crack resistance and its construction method

A technology of crack resistance and node structure, which is applied to the processing of building components, building structures, and building materials. The effect of overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

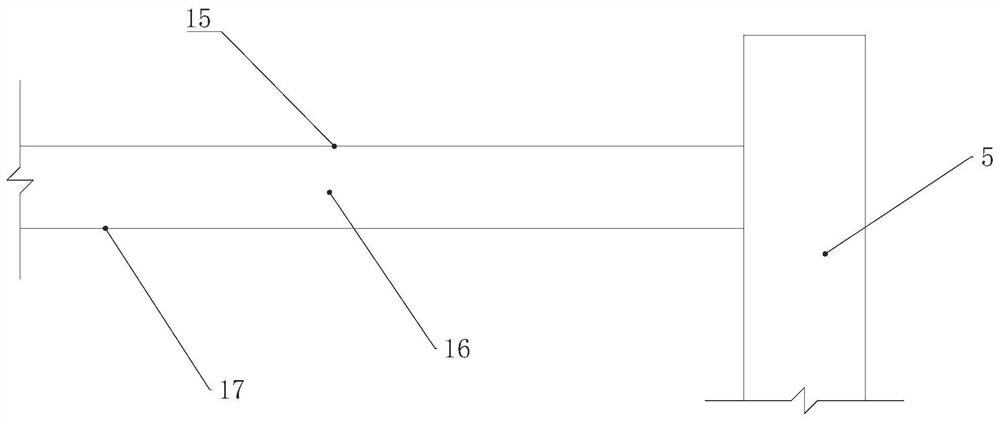

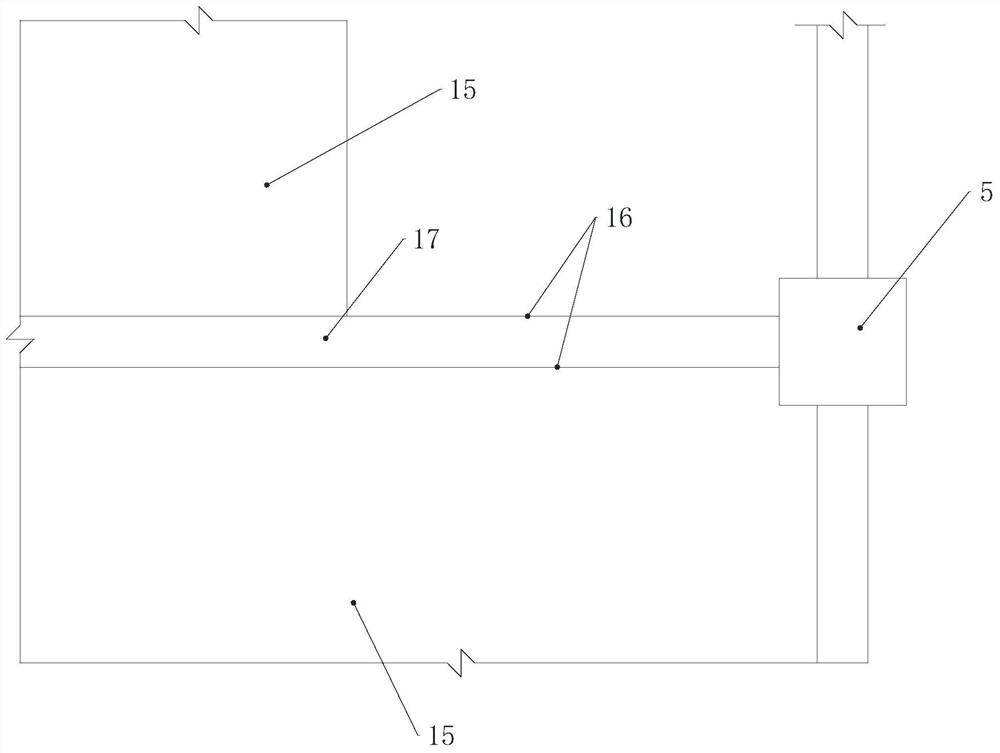

[0062] Such as figure 1 As shown, an upturned beam node structure with good crack resistance in the present invention includes a constant slab 1 , a constant beam 2 , a raised slab 3 , an upturned beam 4 and a beam support 5 . The regular slab 1 is the floor slab of normal elevation, the regular beam 2 is used to support the regular slab 1 which matches with the regular slab 1, the rising slab 3 is the floor slab at the normal elevation, and the upturning beam 4 is used to support the rising slab 3, the beam bottom of the upturned beam 4 is flush with the bottom of the regular beam, and the beam top elevation of the upturned beam 4 is higher than that of the regular beam top. The beam support 5 is connected with the upturned beam and the normal beam.

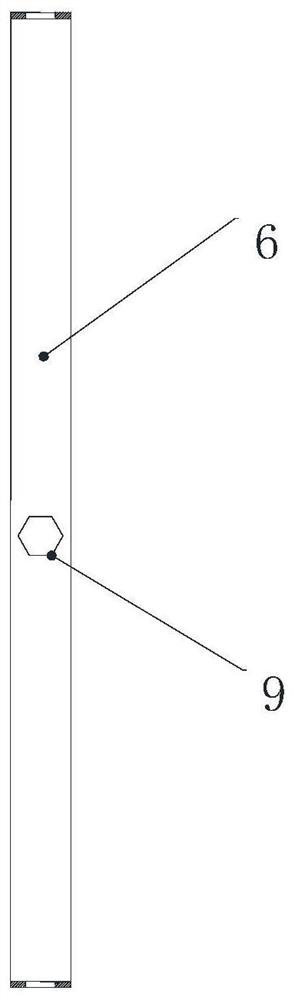

[0063] Inside the upturning beam 4, there are several channel steels 6 arranged in sequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com