Beam upturning joint structure with good anti-cracking performance and construction method thereof

A technology of crack resistance and joint structure, which is applied to the processing of building components, building structures, and building materials. It can solve problems such as rusting of steel bars and unfavorable mechanical properties of beams, and achieve enhanced connection performance, enhanced crack limitation, and ease The effect of the difference in bending stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

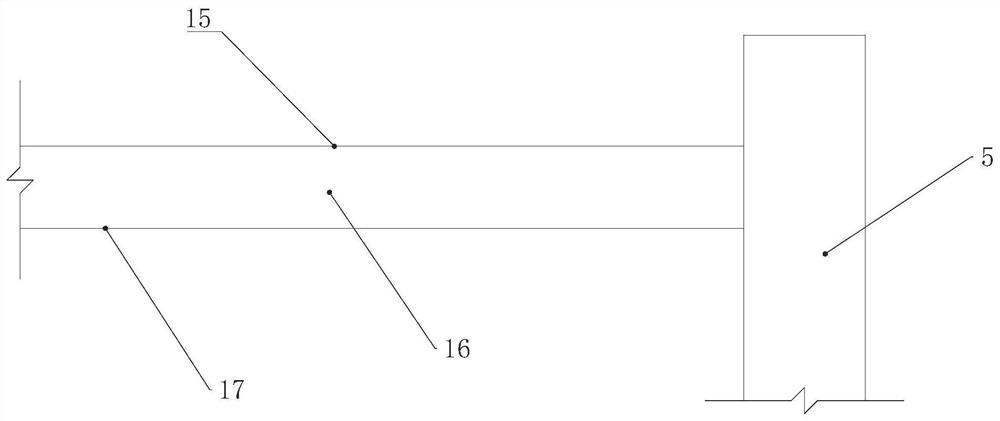

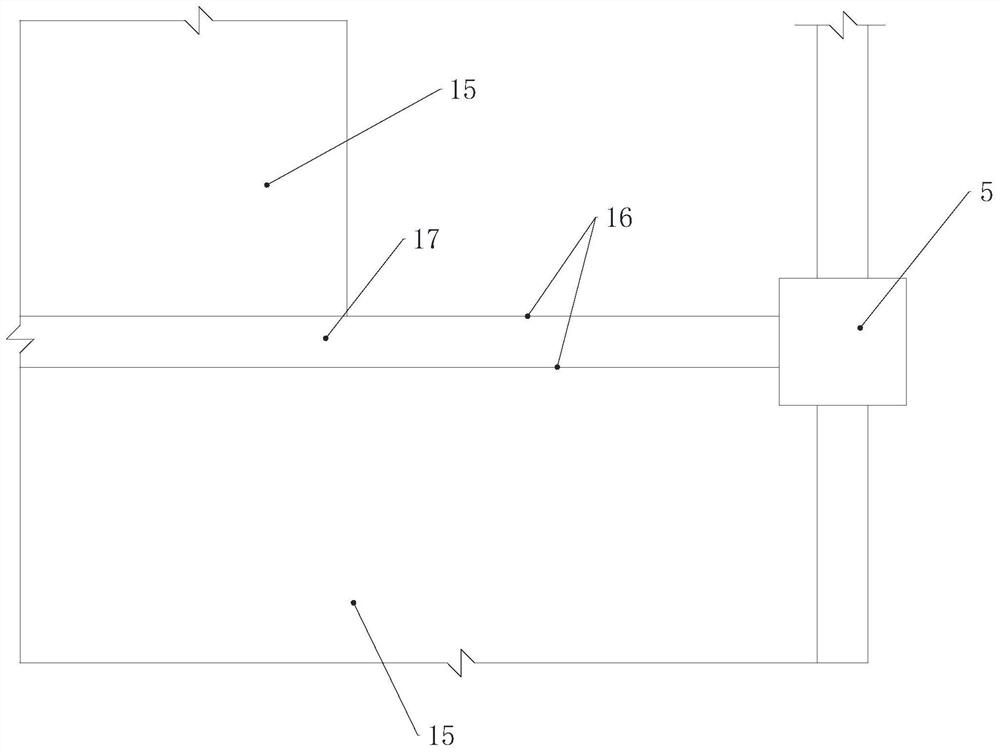

[0062] Such as figure 1 As shown, an upturned beam node structure with good crack resistance in the present invention includes a constant slab 1 , a constant beam 2 , a raised slab 3 , an upturned beam 4 and a beam support 5 . The regular slab 1 is the floor slab of normal elevation, the regular beam 2 is used to support the regular slab 1 which matches with the regular slab 1, the rising slab 3 is the floor slab at the normal elevation, and the upturning beam 4 is used to support the rising slab 3, the beam bottom of the upturned beam 4 is flush with the bottom of the regular beam, and the beam top elevation of the upturned beam 4 is higher than that of the regular beam top. The beam support 5 is connected with the upturned beam and the normal beam.

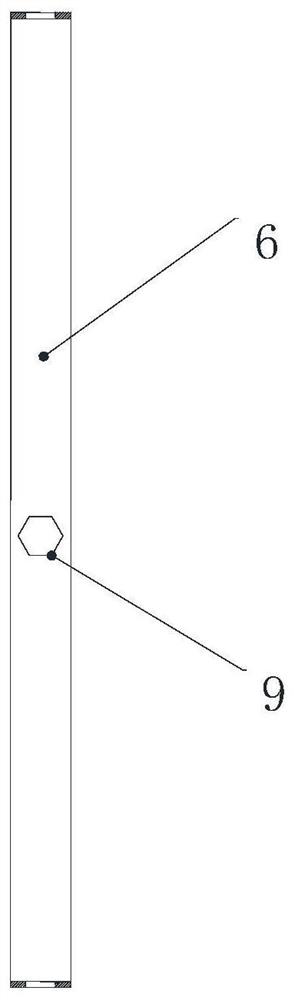

[0063] Inside the upturning beam 4, there are several channel steels 6 arranged in sequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com