Method for preparing graphene masterbatch by water-phase synergistic coagulation process and forming long-service-life loading wheel tire of heavy vehicle

A graphene and ene masterbatch technology, which is applied in the direction of rolling resistance optimization, road transportation emission reduction, etc., can solve the problems that it is difficult to obtain high graphene content masterbatch, graphene oxide and latex have a large difference in specific gravity, and achieve the preparation process Green environmental protection, excellent dispersion effect, and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] ①Preparation of graphene oxide aqueous dispersion: add an anionic surfactant to water, and after thorough mixing, add graphene oxide, and after uniform dispersion, adjust the pH value of the obtained graphene oxide aqueous dispersion to 10 to obtain oxidized graphene oxide. Graphene water dispersion;

[0026] ②Preparation of modified graphene oxide aqueous dispersion: add the surface modifier into the water, after fully mixing, add the graphene oxide dispersion prepared in step 1 into it, then add the activator and catalyst, and react for 6-48h, A stably dispersed modified graphene oxide aqueous dispersion is obtained;

[0027] (3) Preparation of graphene masterbatch by water-phase synergistic coagulation process: adding deionized water to natural latex, then adding the modified graphene oxide aqueous dispersion prepared in step (2), and fully mixing to obtain a uniformly dispersed mixed emulsion. The stable graphene oxide particles will form binding particles with the...

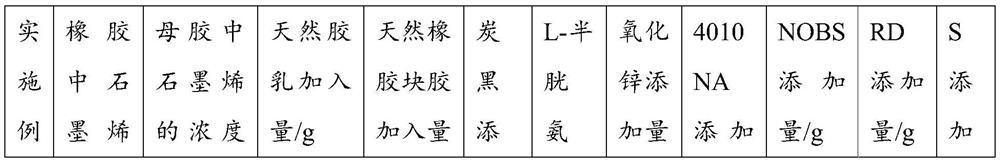

Embodiment 1~4

[0040] The specific execution steps in Embodiments 1 to 4 are:

[0041] ①Add 2g of anionic surfactant alkylbenzene sulfonate into 100ml of water, stir for 10min, then add 1g, 2g, 3g, 4g of graphene oxide powder respectively, and disperse for 30min to obtain a uniform graphene oxide dispersion, Then add 10wt.% ammonia water to it, adjust the pH value to 10, obtain the graphene oxide dispersion liquid of required concentration;

[0042] ②Preparation of modified graphene oxide aqueous dispersion: add 1g of surface modifier L-cysteine to 50ml of hot water, and after the solution is cooled to room temperature, add the graphene oxide dispersion prepared in step ① Add it, stir, add activator 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride 0.02g, catalyst N-hydroxysuccinimide 0.02g, stir and react for 8h to obtain Well-dispersed modified graphene oxide dispersion;

[0043] ③Preparation of graphene masterbatch by water-phase synergistic coagulation process: adding a cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com