Core-shell special-shaped porous carbon sphere and preparation method thereof

A porous carbon, special-shaped technology, applied in the direction of nano-carbon, can solve the problems of difficult adjustment of pore size, limited development of porous carbon spheres, difficult control of morphology, etc., and achieves excellent absorbing performance, simple and easy to operate synthesis method, and good sphericity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

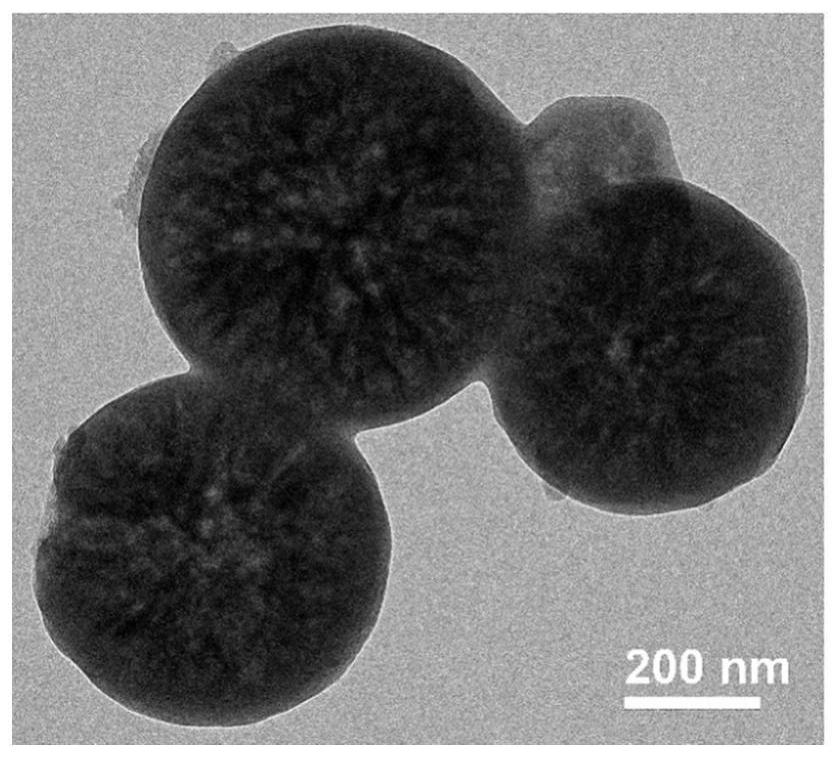

[0025] Mix 40g of ethanol and 80g of water to make a solution. To this mixed solution was added 0.8 g CTAB powder and 0.6 mL NH 4 OH, mechanically stirred at room temperature for 30 min at 600 rpm. 2.4mL of tetraethyl silicate was added to the solution, after 2min, 4.0mL of p-xylene was added, and the reaction was performed for 2h to prepare radial mesoporous SiO 2 Microspheres.

[0026] To the mesoporous SiO prepared above 2 In the microsphere system, 0.75 g of dopamine hydrochloride was added and stirred, and the reaction was fully reacted for 24 hours, and the stirring speed was 800 rpm. The reaction solution was centrifuged and washed, and the resulting powder was lyophilized in a freeze dryer and dried in a vacuum oven at 40°C. The powder was calcined in a tube furnace under nitrogen atmosphere for carbonization. The calcination means that the calcination temperature is gradually increased from room temperature to 350 °C, the heating rate is 5 °C / min, and the tempera...

Embodiment 2

[0030] Mix 50g of ethanol and 80g of water to make a solution. To this mixed solution was added 0.8 g CTAC powder and 1.2 mL NH 4 OH, mechanically stirred at room temperature for 30 min at 800 rpm. Add 3.0 mL of tetrapropyl silicate to the solution, add 4.0 mL of p-xylene after 10 min, and react for 4 h to prepare radial mesoporous SiO 2 Microspheres.

[0031] To the mesoporous SiO prepared above 2 In the microsphere system, 0.9 g of dopamine hydrochloride was added and stirred, and the reaction was fully reacted for 48 hours, and the stirring speed was 800 rpm. The reaction solution was centrifuged and washed, and the resulting powder was lyophilized in a freeze dryer and dried in a vacuum oven at 40°C. The powder was calcined in a tube furnace under nitrogen atmosphere for carbonization. The calcination means that the calcination temperature is gradually increased from room temperature to 350 °C, the heating rate is 5 °C / min, and the temperature is kept at 350 °C for 1 ...

Embodiment 3

[0034] Example 3 (counter example)

[0035] A counter-example is provided here. Compared with Example 1, the dosage of dopamine hydrochloride is reduced, and other conditions remain unchanged.

[0036] Mix 40g of ethanol and 80g of water to make a solution. To this mixed solution was added 0.8 g CTAB powder and 0.6 mL NH 4 OH, mechanically stirred at room temperature for 30 min at 600 rpm. 2.4mL of tetraethyl silicate was added to the solution, after 2min, 4.0mL of p-xylene was added, and the reaction was performed for 2h to prepare radial mesoporous SiO 2 Microspheres.

[0037] To the mesoporous SiO prepared above 2 In the microsphere system, 0.6 g of dopamine hydrochloride was added and stirred, and fully reacted for 24 hours, and the stirring speed was 800 rpm. The reaction solution was centrifuged and washed, and the resulting powder was lyophilized in a freeze dryer and dried in a vacuum oven at 40°C. The powder was calcined in a tube furnace under nitrogen atmosphere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com