Preparation method of special polyester staple fiber for vortex spinning

A polyester staple fiber, vortex spinning technology, applied in the direction of staple fiber formation, melt spinning, fiber processing, etc., can solve the problems of poor twisting effect, long fiber length, low linear density, etc., and achieve stable temperature and fiber length. Long, dry heat stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

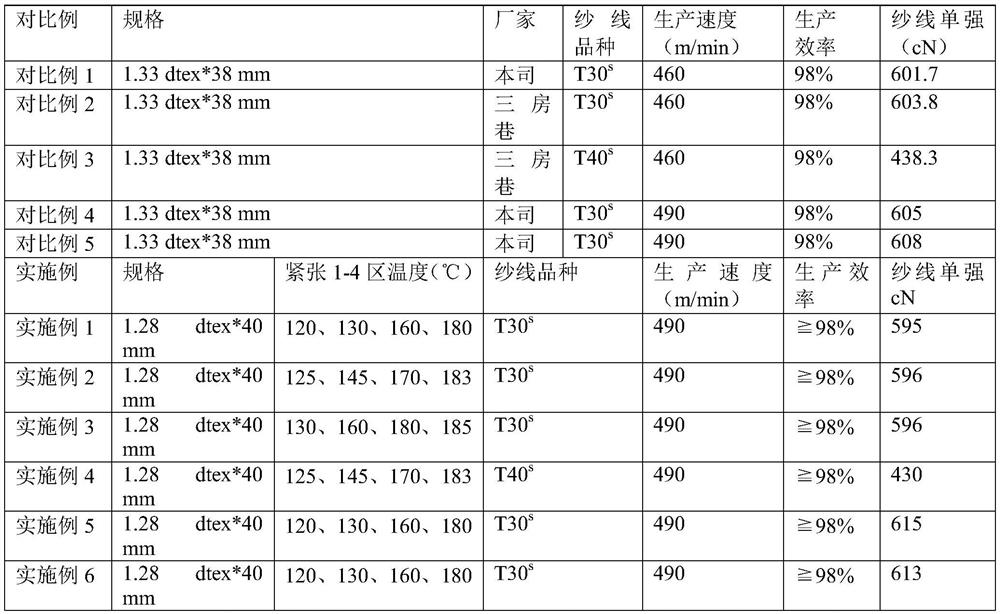

Examples

Embodiment 1

A preparation method of special polyester staple fiber for vortex spinning,

(1) Front spinning. The high-temperature melt after the final polymerization kettle is processed into a certain length of raw tow for post-spinning processing through spinning, cooling, oiling, winding, and filament-filling processes.

[0022] The polyester melt (intrinsic viscosity is 0.650) is obtained by conventional polymerization, and the raw tow of 4.2dtex is made under the spinning process speed of 1380m / min, and the spinning temperature is 298°C; Blowing humidity 80%, blowing speed 1.5m / s, EYS1.5 average value of raw tow is 160, EYS1.5 CV value average 6.0, breaking elongation average 365, breaking elongation CV value average 6.0.

[0023] (2) After spinning. The obtained raw tow is successively bundled, first-stage drafting, second-stage drafting, 20-roll tension heat-setting, three-stage drafting, crimping, relaxation heat-setting, cutting and packaging processes, to obtain 1.28dtex*40mm sp...

Embodiment 2

Embodiment 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com