Carbon dot/silicon dioxide composite material as well as preparation method and application thereof

A composite material, silica technology, applied in chemical instruments and methods, special compound water treatment, physical/chemical process catalysts, etc., can solve problems such as separation difficulties, achieve high photocatalytic activity, good light confinement ability, large ratio The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1SiO 2 and carbon dots / SiO 2 Synthesis of composite materials

[0038] Synthesis of SiO by Sol Method 2 and carbon dots / SiO 2 composite material.

[0039] The carbon dot solution used is the blue light carbon dot solution synthesized by the hydrothermal method, and the specific process is as follows: the carbon dot solution is prepared by the hydrothermal method, and the reagents used are absolute ethanol, tryptophan, o-phenylenediamine, concentrated hydrochloric acid (mass fraction. 38%), the above reagents were mixed uniformly with magnetic stirring in the autoclave. Put the sealed reaction kettle into an oven, set the temperature to 160 °C and heat for 7 h, and take it out after the temperature is cooled to room temperature, and the obtained carbon dot solution is filtered and sealed for storage.

[0040] Blank sample SiO 2 Preparation process: add 50 mL of anhydrous ethanol solution to the beaker, then add 2 mL of tetraethyl silicate, magnetically stir...

Embodiment 2

[0042] Example 2SiO 2 and carbon dots / SiO 2 Application of composite materials in photocatalytic removal of uranium

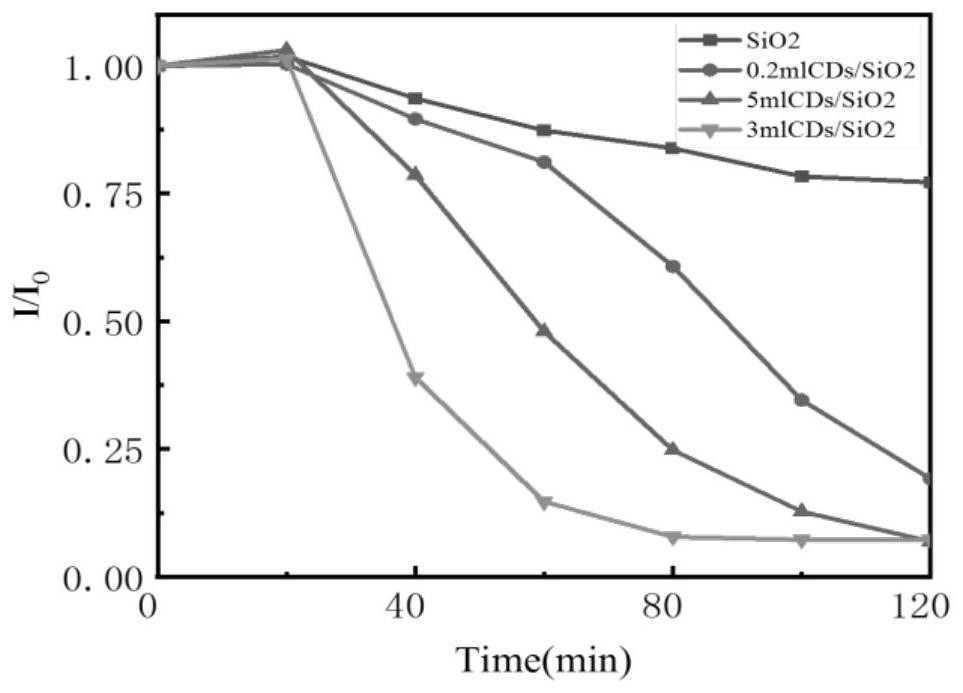

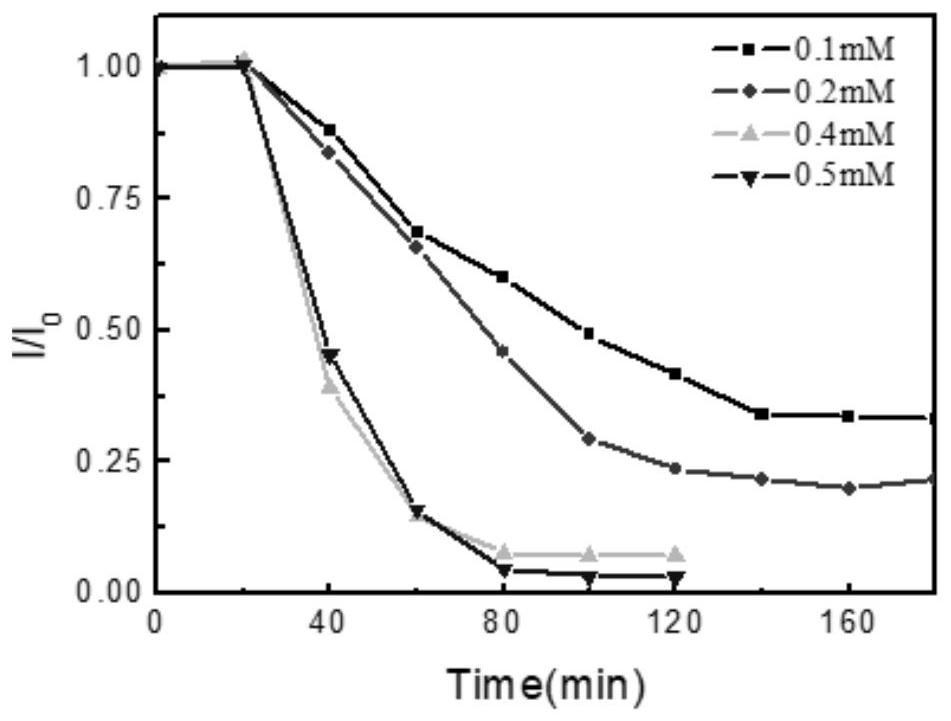

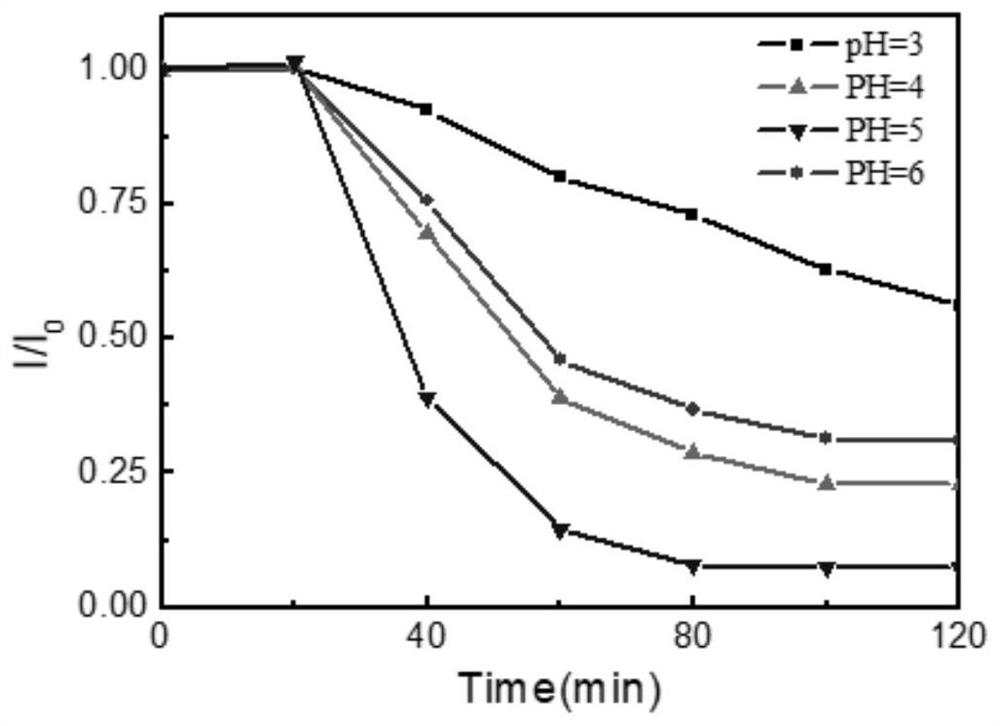

[0043] 30mg SiO 2 and 30mg carbon dots / SiO 2 The composite material was used for photocatalytic removal of uranium solution with a concentration of 0.4 mM and a volume of 50 mL. It was reacted in the dark for 1 h under dark conditions, and then placed in a photoreaction box, and a 425 nm filter was added to obtain visible light conditions. Begin under visible light conditions, begin to carry out photocatalytic reaction, take a sample every 20min, use the mixed solution of tartaric acid+diluted nitric acid+arsazo III as color developer, place it in a spectrophotometer and measure its absorbance at 652nm. The experimental results are as figure 1 shown, it is SiO 2 and different carbon dots / SiO 2 Comparison of photocatalytic removal of uranium by composite materials. It can be clearly seen that the composite material added with carbon dots is better than Si...

Embodiment 3

[0045] Embodiment 3 The research of recycling performance

[0046] To study the carbon dots / SiO of the present invention 2 The practical applicability of the composite was tested for its photocatalytic cycling performance. The specific operation process is as follows: according to the operation process of Example 2, the photocatalysis is performed once, and the absorbance is measured about an hour after the light is turned on, and the measured value reaches more than 0.8h. At this time, 10mL of dilute HNO is added to the remaining solution. 3 solution, let stand for half an hour, and measure the absorbance value of uranium until it returns to the initial value. Then centrifuged, washed twice with pure water, poured off the supernatant and added new uranium solution to start a new round of photocatalysis. The experimental results are as Image 6 As shown, after 5 cycles, the carbon dots / SiO prepared in Example 1 2 The photocatalytic performance of the composite material for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com