MPCVD equipment capable of realizing effective doping

A technology of equipment and pipelines, applied in the field of plasma chemical vapor deposition, can solve the problems such as the exploration, research and application realization of in-situ doping technology that restricts MPCVD, less attention to MPCVD research, impurity memory effect and contamination, etc. Doping contamination and memory effect, or the effect of overcoming doping contamination and memory effect and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

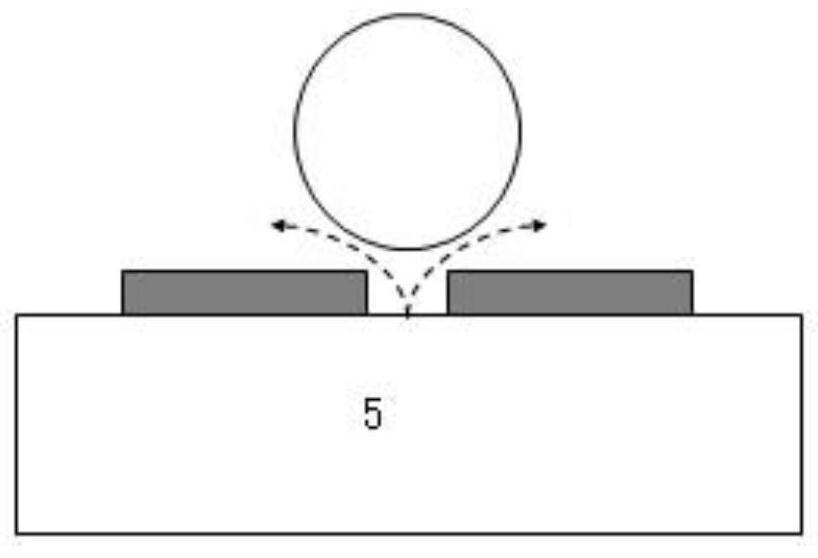

[0028] Embodiment 1, the second gas transmission ring 4 is located in the ring gas transmission structure in the center of the support

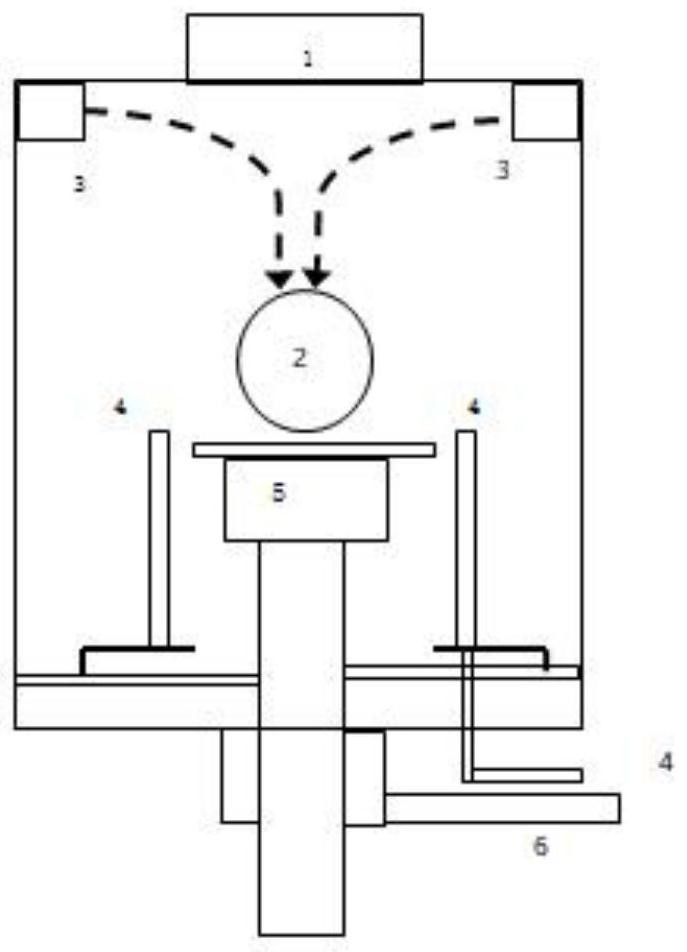

[0029] Open a small hole in the center of the substrate support 5, the diameter of which is less than 0.6 cm, to ensure that its influence on the microwave coupling and the formation of the plasma ball 2 is reduced to a controllable range, and a suitable structure is processed under the substrate support 5, The second dopant gas and buffer gas are introduced from the outside of the reaction chamber to the central gas delivery ring. The center above the reaction chamber is a microwave window 1 .

[0030] The central gas transmission ring adopts a central radial ring structure, and its material can be quartz or corundum, or metal such as stainless steel or molybdenum, such as figure 2 shown.

[0031] The horizontal height difference between the gas injection hole on the second circular ring structure and the support plane is between 0.5 cm a...

Embodiment 2

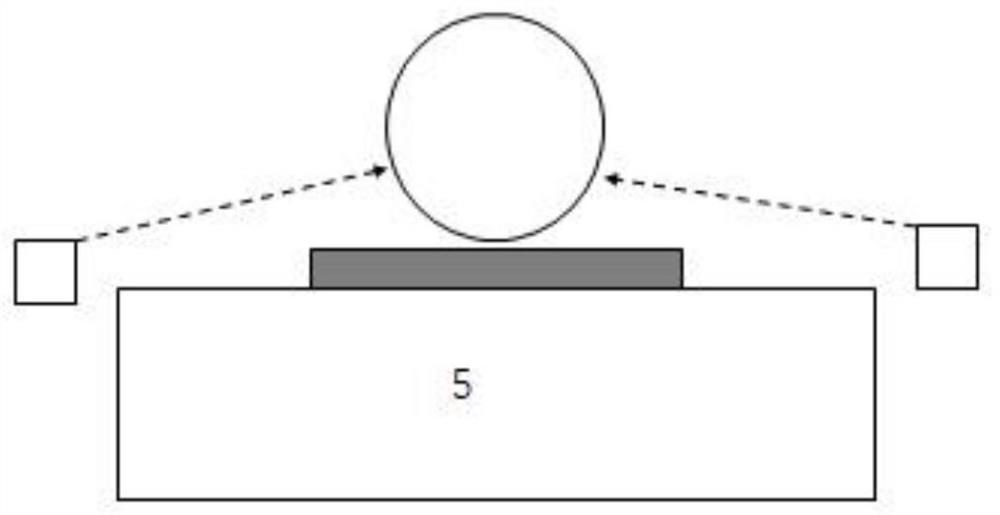

[0041] Embodiment 2, the structure in which the second gas transmission ring 4 is located around the support and keeps a certain distance from the support

[0042] Fix a circular ring around the substrate support, with a diameter of more than 6cm, and maintain a suitable distance from the edge of the substrate support to ensure that its influence on microwave coupling and plasma ball formation is reduced to a controllable range. And it is coupled with a suitable exhaust structure to ensure the normal and effective discharge of reaction waste gas.

[0043] Process a suitable support and gas connection structure under the substrate support or circular ring, and introduce the second channel of dopant gas and buffer gas from outside the reaction chamber to the surrounding gas delivery ring.

[0044] The surrounding gas transmission ring adopts a circular ring structure radial to the center, and its material can be quartz or corundum, or metal such as stainless steel or molybdenum,...

Embodiment 3

[0055] Embodiment 3, the structure in which the second gas transmission ring 4 is located around the support and in close contact with the support

[0056] Fix a circular ring around the substrate support and keep it in close contact with the edge of the substrate support to ensure that its influence on microwave coupling and plasma ball formation is reduced to a controllable range. Appropriate support and gas connection structures are processed below, and the second dopant gas and buffer gas are introduced from the outside of the reaction chamber to the surrounding gas delivery ring, such as Figure 4 shown.

[0057] The central gas transmission ring adopts a central radial ring structure, and its material can be quartz or corundum, or metal such as stainless steel or molybdenum.

[0058] The height difference between the gas injection holes on the circular ring structure and the plane of the support is between 0.5 cm and -0.5 cm, so as to facilitate the control of the spati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com