Method for treating flammulina velutipes cultivation waste as well as product and application thereof

A technology for Flammulina velutipes and waste, applied in the field of biological agriculture, can solve the problems of low calorific value and low added value, and achieve the effects of high total carbon content, increased added value and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

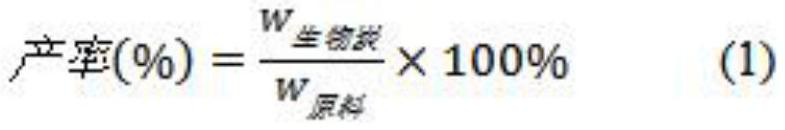

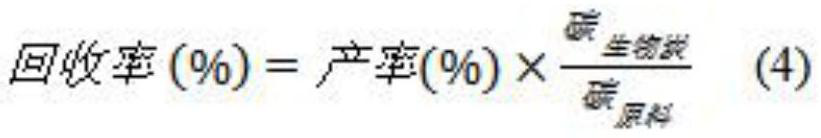

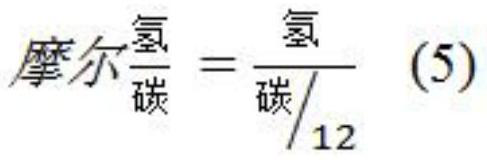

Method used

Image

Examples

Embodiment 1

[0023] The biochar used in the experiment came from the cut root of Flammulina velutipes. Cut root stock was dried in an oven at 55 °C to constant weight. Weigh 30-50 g of dry raw materials, place them in a tube furnace, and set the carbonization temperature at 300°C. Before heating up, use an air pump to evacuate the entire pipeline into a vacuum (-0.5MPa), and then pass helium until the gas outlet reaches (+0.02MPa). At this time, the pyrolysis atmosphere in the furnace is high-purity helium. The heating rate is 10~15℃min -1 , keep warm for 2h, cool to room temperature and take out. The solid product is root-cut charcoal and stored in a desiccator at 300°C until use.

Embodiment 2

[0025] The biochar used in the experiment came from the cut root of Flammulina velutipes. Cut root stock was dried in an oven at 55 °C to constant weight. Weigh 30-50 g of dry raw materials, place them in a tube furnace, and set the carbonization temperature at 500°C. Before heating up, use an air pump to evacuate the entire pipeline into a vacuum (-0.5MPa), and then pass helium until the gas outlet reaches (+0.02MPa). At this time, the pyrolysis atmosphere in the furnace is high-purity helium. The heating rate is 10~15℃min -1 , keep warm for 2h, cool to room temperature and take out. The solid product is root-cut charcoal at 500°C, and it is stored in a desiccator until use.

Embodiment 3

[0027] The biochar used in the experiment was derived from Flammulina velutipes mushroom residue. Cut root stock was dried in an oven at 55 °C to constant weight. Weigh 30-50 g of dry raw materials, place them in a tube furnace, and set the carbonization temperature at 300°C. Before heating up, use an air pump to evacuate the entire pipeline into a vacuum (-0.5MPa), and then pass helium until the gas outlet reaches (+0.02MPa). At this time, the pyrolysis atmosphere in the furnace is high-purity helium. The heating rate is 10~15℃min -1 , keep warm for 2h, cool to room temperature and take out. The solid product is mushroom residue charcoal, and it is stored in a desiccator at 300°C until use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com