Method for preparing 4-(4-methylphenoxy) benzylamine through catalysis of modified nano nickel

A technology of methylphenoxy and nano-nickel, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of amino hydroxyl compounds, etc., can solve problems such as low product purity, high production cost, and poor preparation efficiency, and achieve The effect of simple process route, low production cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

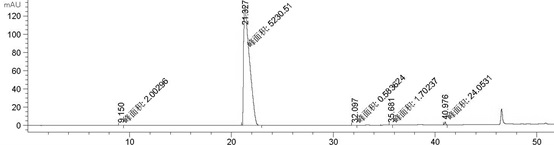

Examples

Embodiment 1

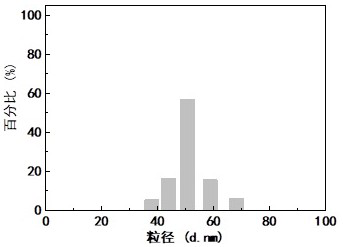

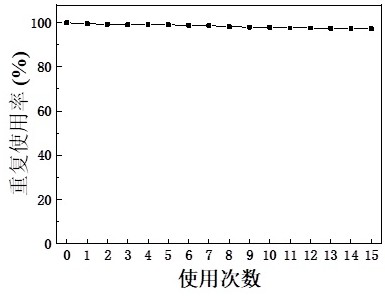

[0031] Embodiment 1 Utilizes the method for synthesizing 4-(4-methylphenoxy)benzylamine catalyzed by modified nano-nickel:

[0032] (1) Add 1 L of water, 60 g of nickel chloride, and 10 g of Span-20 into a beaker, stir and mix, add 10 g of sodium borohydride, adjust the pH to 10 with 1 mol / L sodium hydroxide solution, and carry out Ultrasonic treatment, the ultrasonic power is 1000 W, and the reaction time is 30 min. After the reaction, the modified nano-nickel is obtained after centrifugation, washing and drying;

[0033] (2) Add 1 L of water, 1.5 kg of potassium hydroxide, 2.5 kg of p-cresol, and 10 L of dimethyl sulfoxide into the reaction kettle, stir and mix and heat to 150°C, then add 3 kg of p-chlorobenzonitrile, continue Stir the reaction, finish the reaction after 3 h of reaction, recover the organic solvent, add water to cool down to room temperature, and then filter, wash and dry the reaction solution to obtain 4-(4-methylphenoxy)benzonitrile;

[0034] (3) In the a...

Embodiment 2

[0035] Embodiment 2 Utilizes the method for synthesizing 4-(4-methylphenoxy)benzylamine catalyzed by modified nano-nickel:

[0036] (1) Add 1 L of water, 60 g of nickel chloride, and 10 g of Span-60 into a beaker, stir and mix, add 10 g of sodium cyanoborohydride, and adjust the pH to 10 with 1 mol / L sodium hydroxide solution. And carry out ultrasonic treatment, the ultrasonic power is 1500 W, and the reaction time is 30 min. After the reaction, the modified nano-nickel is obtained after centrifugation, washing and drying;

[0037] (2) Add 1 L of water, 1.5 kg of potassium hydroxide, 2.5 kg of p-cresol, and 10 L of dimethyl sulfoxide into the reaction kettle, stir and mix and heat to 150°C, then add 3 kg of p-chlorobenzonitrile, continue Stir the reaction, finish the reaction after 3 h of reaction, recover the organic solvent, add water to cool down to room temperature, and then filter, wash and dry the reaction solution to obtain 4-(4-methylphenoxy)benzonitrile;

[0038] (3)...

Embodiment 3

[0039] Embodiment 3 Utilizes the method for synthesizing 4-(4-methylphenoxy)benzylamine catalyzed by modified nano-nickel:

[0040](1) Add 1 L of ethanol, 50 g of nickel nitrate, and 20 g of Span-20 into a beaker, stir and mix, add 10 g of sodium borohydride, adjust the pH to 10 with 1 mol / L sodium hydroxide solution, and perform ultrasonication treatment, the ultrasonic power was 1000 W, and the reaction time was 60 min. After the reaction, the modified nano-nickel was obtained after centrifugation, washing and drying;

[0041] (2) Add 1 L of water, 1.5 kg of potassium hydroxide, 2.5 kg of p-cresol, and 10 L of toluene into the reaction kettle, stir and mix and heat to 150°C, then add 3 kg of p-chlorobenzonitrile, continue to stir and react, and react After 3 h, the reaction was terminated, the organic solvent was recovered, the temperature was lowered to room temperature by adding water, and the reaction solution was filtered, washed and dried to obtain 4-(4-methylphenoxy)be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com