Lithium battery pole piece, lithium battery cell and preparation method of lithium battery pole piece

A lithium battery and pole piece technology is applied in the preparation of lithium battery cells and lithium battery pole pieces, and in the field of lithium battery pole pieces, and can solve the problems of high cost, complex equipment structure, and difficulty in battery stacking or assembly. , to achieve the effect of eliminating powder, simple equipment, and reducing the risk of puncturing the diaphragm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The invention provides a novel preparation method of lithium battery pole piece, which adopts continuous direct coating to reduce the difficulty of coating, and adopts intermittent direct coating and split coating, which can greatly save electrode slurry, and the preparation process uses The equipment is simple, which greatly reduces the waste of pole pieces caused by rolling broken strips, slitting, die-cutting, wrinkling, etc., and greatly reduces the cost; in addition, a frame-shaped material ring is set on the periphery of the electrode coating, so that During slitting, it can avoid burrs on the pole piece and reduce the risk of burrs piercing the diaphragm; wrapping the electrode slurry in the frame-shaped material ring can greatly solve the risk of battery slurry powder dropping; the frame-shaped material ring has insulation As a result, the safety of lithium batteries is greatly improved; the assembly of lithium battery cells adopts different methods for stacking ...

Embodiment 1

[0097] This embodiment provides a preparation method of a lithium battery pole piece, the preparation method comprising the following steps:

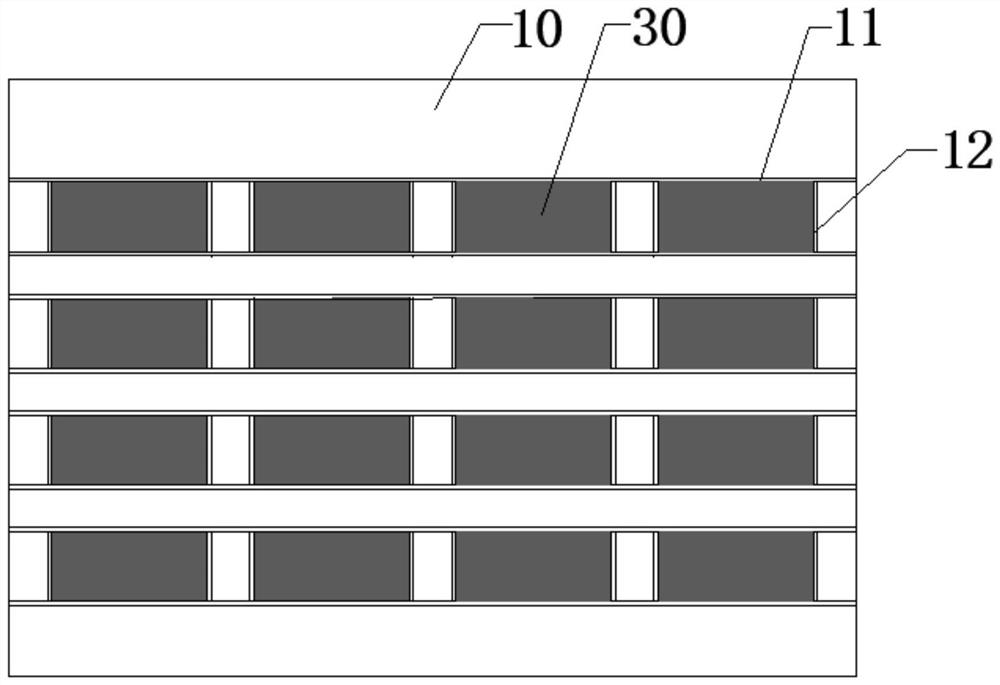

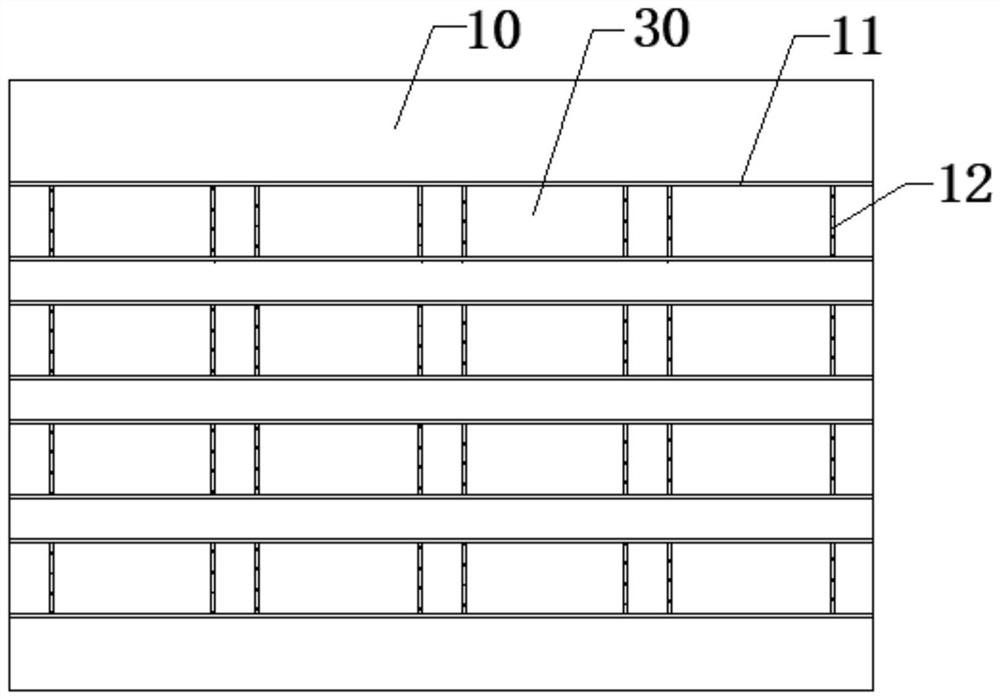

[0098] S1. Refer to figure 1 As shown, a metal substrate 10 is provided, and electrode slurry and ceramic slurry are coated on both sides of the metal substrate 10 to form a frame-shaped bead 20 and an electrode coating 30 located in the frame-shaped bead 20 to obtain double-sided Coated pole piece; wherein, the electrode slurry and the ceramic slurry are coated on both sides of the metal substrate 10, specifically including the following steps: S11, directly coating the ceramic slurry along the horizontal continuity of the metal substrate 10 to form multiple A first ceramic edge 21; S12, intermittently directly coating ceramic slurry and electrode slurry along the longitudinal direction of the metal substrate 10 to form a plurality of second ceramic edges 22, and two second ceramic edges 22 adjacent to each other laterally Vertically ...

Embodiment 2

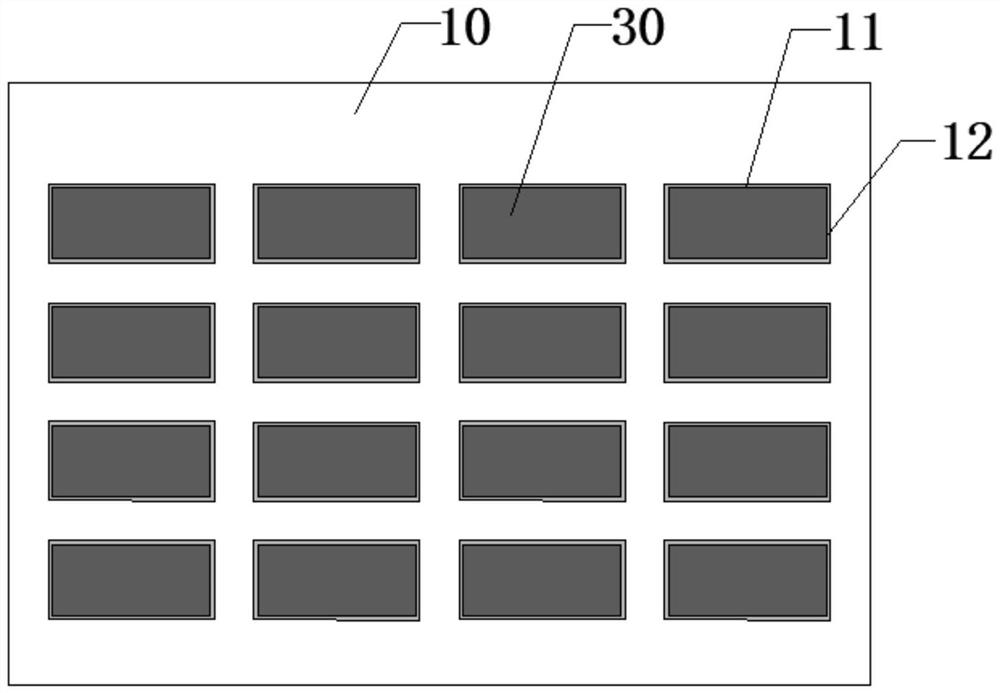

[0105] This embodiment provides a method for preparing lithium battery pole pieces. The difference between this preparation method and Embodiment 1 is that in step S1, refer to figure 2 As shown, when the electrode slurry and the ceramic slurry are coated on both sides of the metal substrate 10, the ceramic slurry is applied intermittently along the horizontal direction of the metal substrate 10 in step S11, and the ceramic slurry is directly applied along the vertical direction of the metal substrate 10 in S12. The ceramic slurry and the electrode slurry are applied intermittently directly, and the width of the formed first ceramic edge 21 and the second ceramic edge 22 is 5 mm, and the thickness of the first ceramic edge 21 and the second ceramic edge 22 is 10 μm. Other methods and steps are the same as those in Embodiment 1, and will not be repeated here.

[0106] This embodiment also provides a lithium battery pole piece. The lithium battery pole piece includes a positive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com