Silicon carbide MOSFET of integrated grid-controlled diode with high surge current resistance

A gate-controlled diode and surge current technology, which is applied in the direction of high-efficiency power electronic conversion, circuits, electrical components, etc., can solve the problems of reducing the reliability of the gate oxide layer of gate-controlled diodes, so as to improve long-term reliability and reduce cell Effect of increased size and reduced switching loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

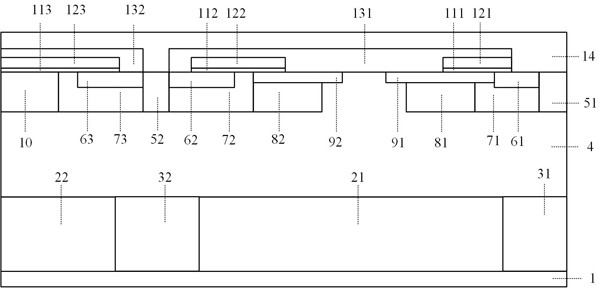

[0032] The cellular structure of the present invention is as figure 1 shown in figure 1 Each part includes backside metal 1, first N-type silicon carbide substrate 21, second N-type silicon carbide substrate 22, first P-type backside implant 31, second P-type backside implant 32, N-type silicon carbide epitaxy 4 , the first P-type source implant 51, the second P-type source implant 52, the first N-type source implant 61, the second N-type source implant 62, the third N-type source implant 63, the first P-type Well region 71, second P-type well region 72, third P-type well region 73, first P-type buried layer 81, second P-type buried layer 82, first N-type conduction layer 91, second N-type conduction layer Flow layer 92, N-type JFET i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Doping concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com