Substrate-free one-step synthesis method of yellow green solid carbon dots

A yellow-green, matrix-free technology, used in chemical instruments and methods, nanocarbons, luminescent materials, etc., can solve the problems of cumbersome synthesis steps of solid carbon dots, and achieve the effects of low cost, broad application prospects and excellent fluorescence properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Dissolve 1 mmol of resorcinol in 10 mL of absolute ethanol, ultrasonically treat it for 25 min at an ultrasonic frequency of 160 W, add 1 mL of m-xylylenediamine after it is completely dissolved, continue to ultrasonicate for 10 min, and then transfer the mixed solution into 25 mL of polytetrafluoroethylene. The vinyl fluoride reactor was lined, put into a stainless steel reactor, put into an electric heating blast drying oven, and reacted at 200°C for 6 hours. After the reaction is completed, the reaction kettle is naturally cooled to room temperature, and the supernatant liquid after the reaction is taken out; the supernatant liquid obtained after the reaction is subjected to suction filtration using a 0.22 μm filter membrane to remove impurities such as large particles, and then the solution is introduced. Naturally volatilized in the petri dish to obtain solid luminescent yellow-green carbon dots.

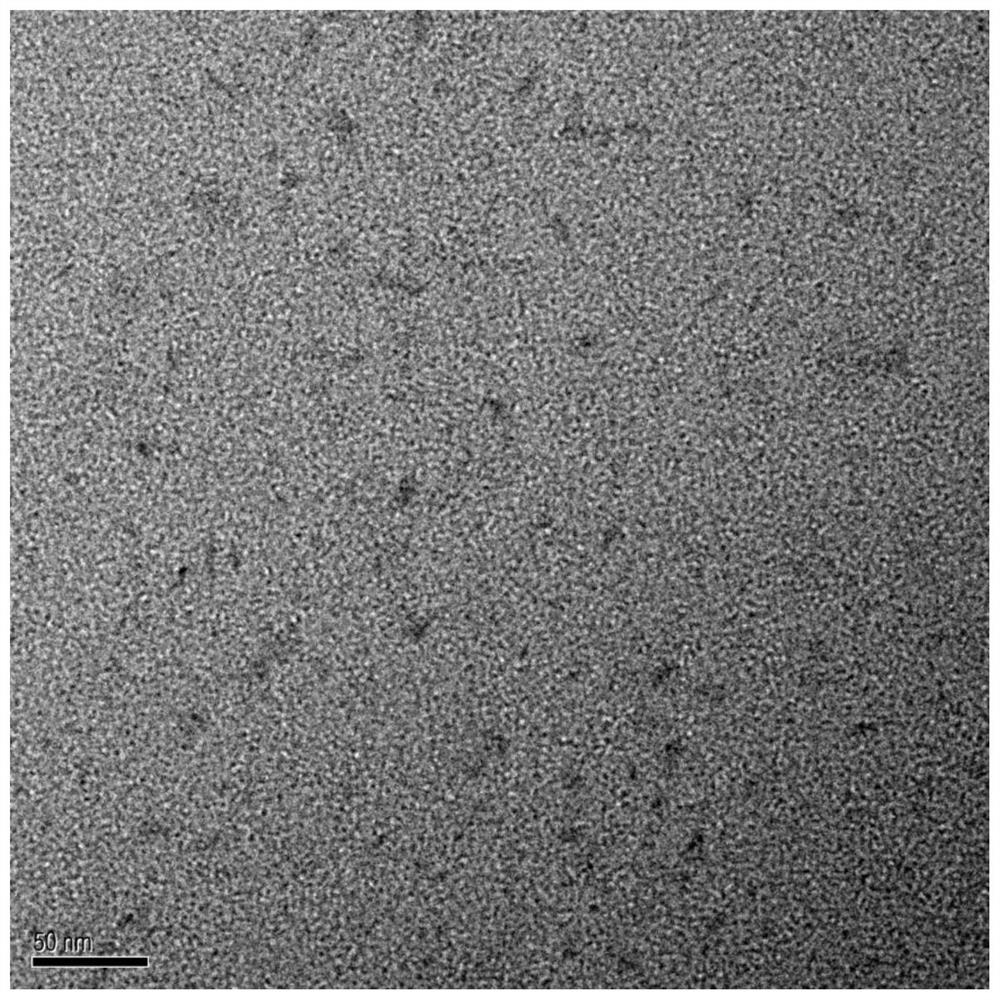

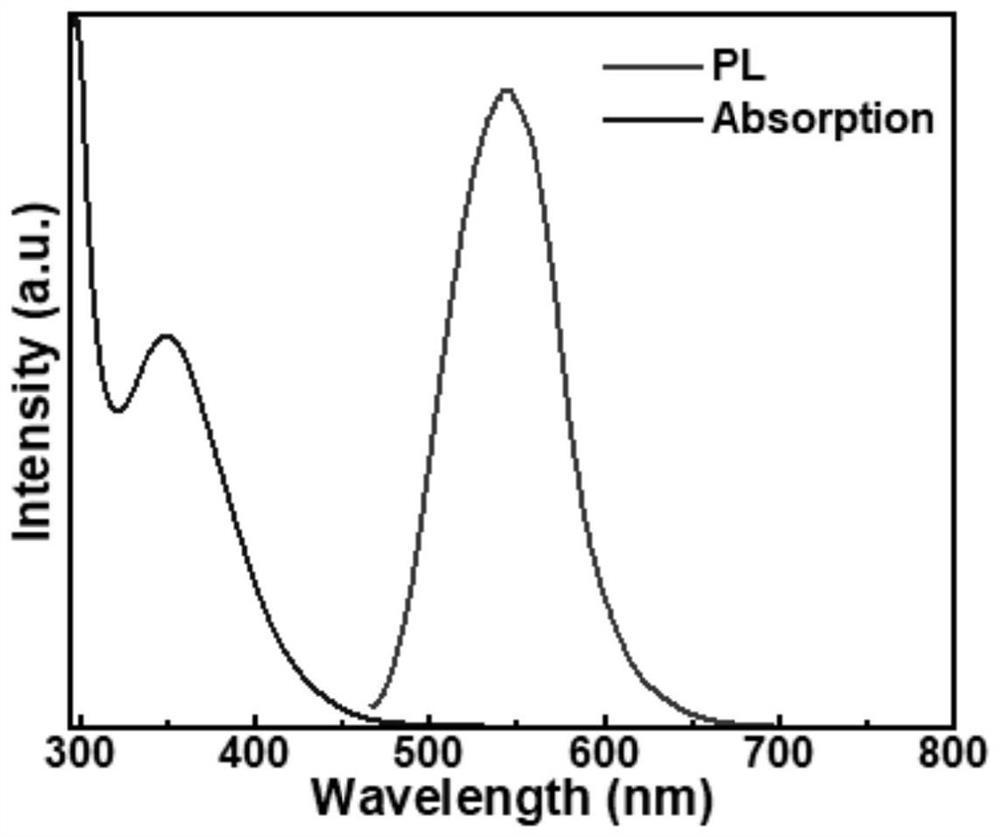

[0029] see figure 1 , figure 1 The optical images of the solid ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com